LT3081

21

3081fc

For more information www.linear.com/LT3081

applicaTions inForMaTion

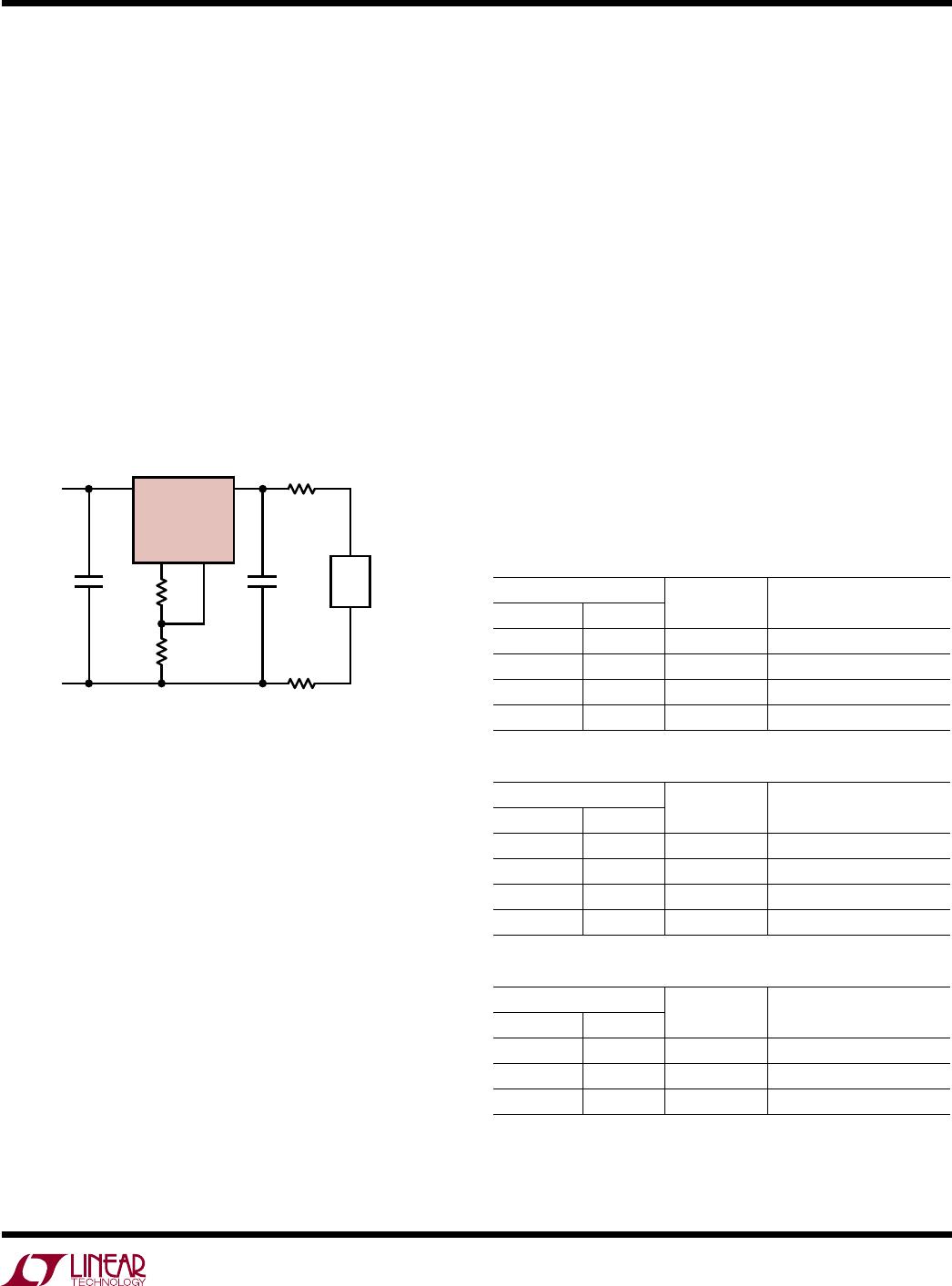

The second technique for reducing power dissipation,

shown in Figure 13, uses a resistor in parallel with the

LT3081. This resistor provides a parallel path for current

flow, reducing the current flowing through the LT3081.

This technique works well if input voltage is reasonably

constant and output load current changes are small. This

technique also increases the maximum available output

current at the expense of minimum load requirements.

R

P

dissipates 1.52W of power. As with the first technique,

choose appropriate wattage resistors to handle and dis-

sipate the

power properly. With this configuration, the

LT3081

supplies only 0.86A. Therefore, load current can

increase by 0.64A to a total output current of 2.14A while

keeping the LT3081 in its normal operating range.

High Temperature Operation

Care must be taken when designing the LT3081H/

LT3081MP applications to operate at high ambient tem

-

peratures. The LT3081

H/LT3081MP operates at high

temperatures, but erratic operation can occur due to un-

foreseen variations

in

external components. Some tantalum

capacitors are available for high temperature operation, but

ESR is often several ohms; capacitor ESR above 0.5Ω is

unsuitable for use with the LT3081H/LT3081MP. Multiple

ceramic capacitor manufacturers

now offer

ceramic capaci-

tors that are rated to 150°C using an X8R dielectric. Check

each

passive component for absolute value and voltage

ratings over the operating temperature range.

Leakages in capacitors or from solder flux left after insuf

-

ficient board cleaning adversely affects low current nodes,

such

as the SET, I

MON

, and TEMP pins. Consider junction

temperature increase due to power dissipation in both

the junction and nearby components to ensure maximum

specifications are not violated for the LT3081H/LT3081MP

or external components.

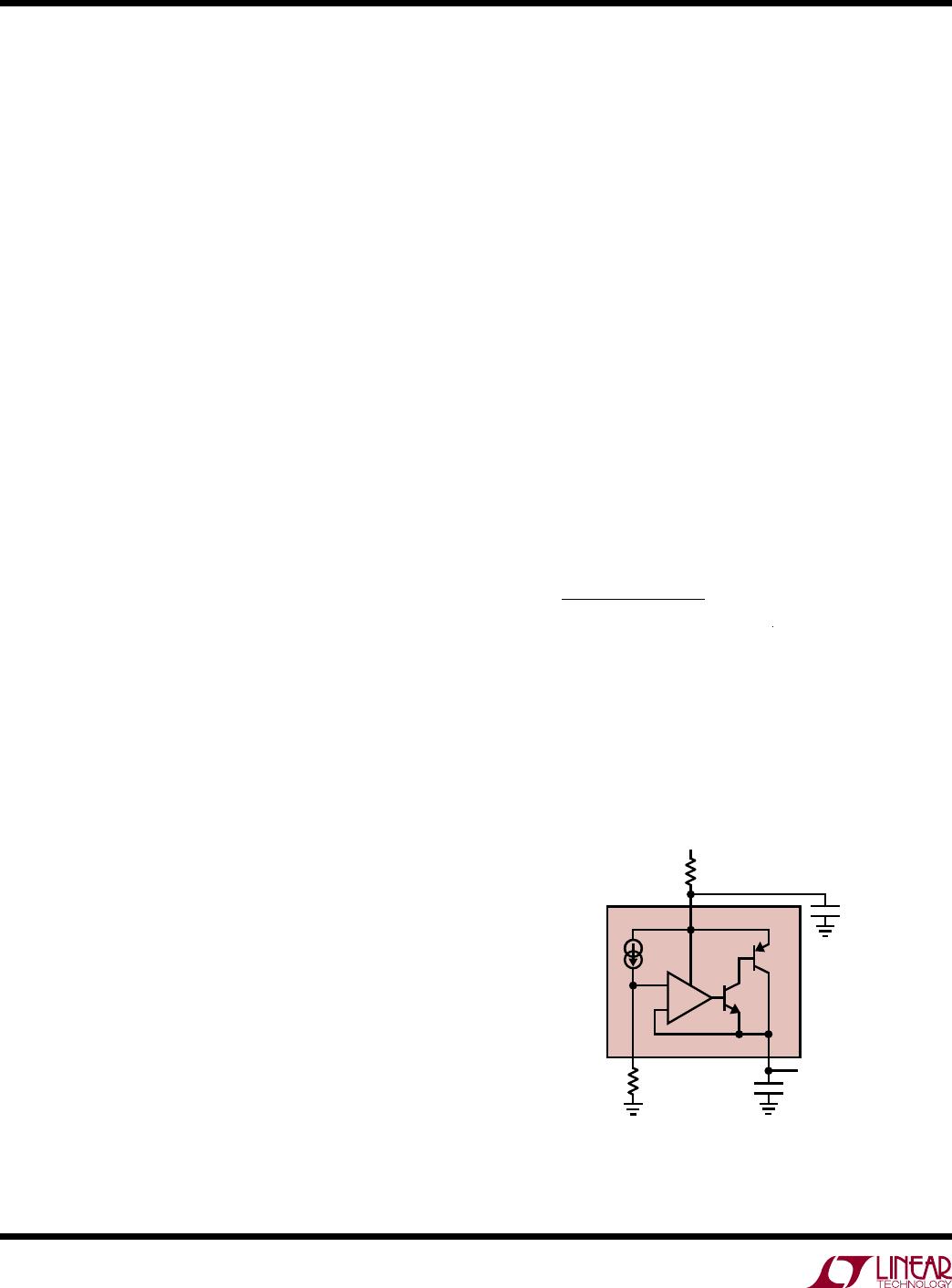

Protection Features

The LT3081 incorporates several protection features ideal

for harsh industrial and automotive environments, among

other applications. In addition to normal monolithic regula

-

tor protection features such as current limiting and thermal

limiting, the LT3081 protects itself against reverse-input

voltages, reverse-output voltages, and large OUT-to-SET

pin voltages.

Current limit protection and thermal overload protection

protect the IC against output current overload conditions.

For normal operation, do not exceed the rated absolute

maximum junction temperature. The thermal shutdown

circuit’s temperature threshold is typically 165°C and

incorporates about 5°C of hysteresis.

3081 F13

IN

SET OUT

+

–

LT3081

50µA

R

SET

V

OUT

V

IN

C2

C1

R

P

Figure 13. Reducing Power Dissipation Using a Parallel Resistor

As an example, assume: V

IN

= 5V, V

IN(MAX)

= 5.5V, V

OUT

= 3.3V, V

OUT(MIN)

= 3.2V, I

OUT(MAX)

= 1.5A and I

OUT(MIN)

= 0.7A. Also, assuming that R

P

carries no more than 90%

of I

OUT(MIN)

= 630mA.

Calculating R

P

yields:

R

P

=

= 3.65Ω

(5% Standard value = 3.6Ω)

The maximum total power dissipation is:

(5.5V – 3.2V) • 1.5A = 3.5W

However, the LT3081 supplies only:

1.5A –

= 0.86A

Therefore, the LT3081’s power dissipation is only:

P

DISS

= (5.5V – 3.2V) • 0.86A = 1.98W