LT3008 Series

13

3008fc

APPLICATIONS INFORMATION

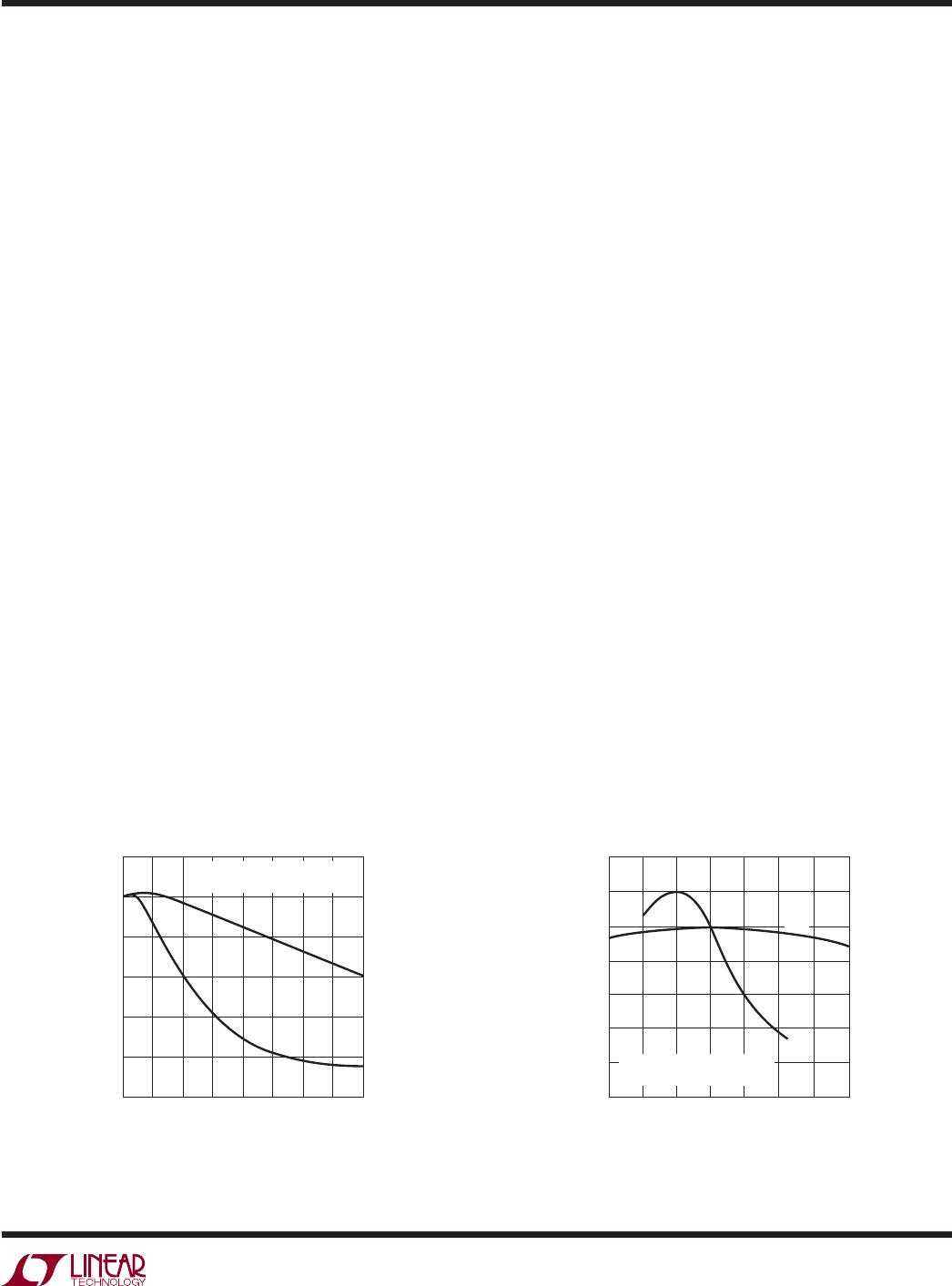

DC BIAS VOLTAGE (V)

CHANGE IN VALUE (%)

3008 F03

20

0

–20

–40

–60

–80

–100

0

4

8

10

26

12

14

X5R

Y5V

16

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10µF

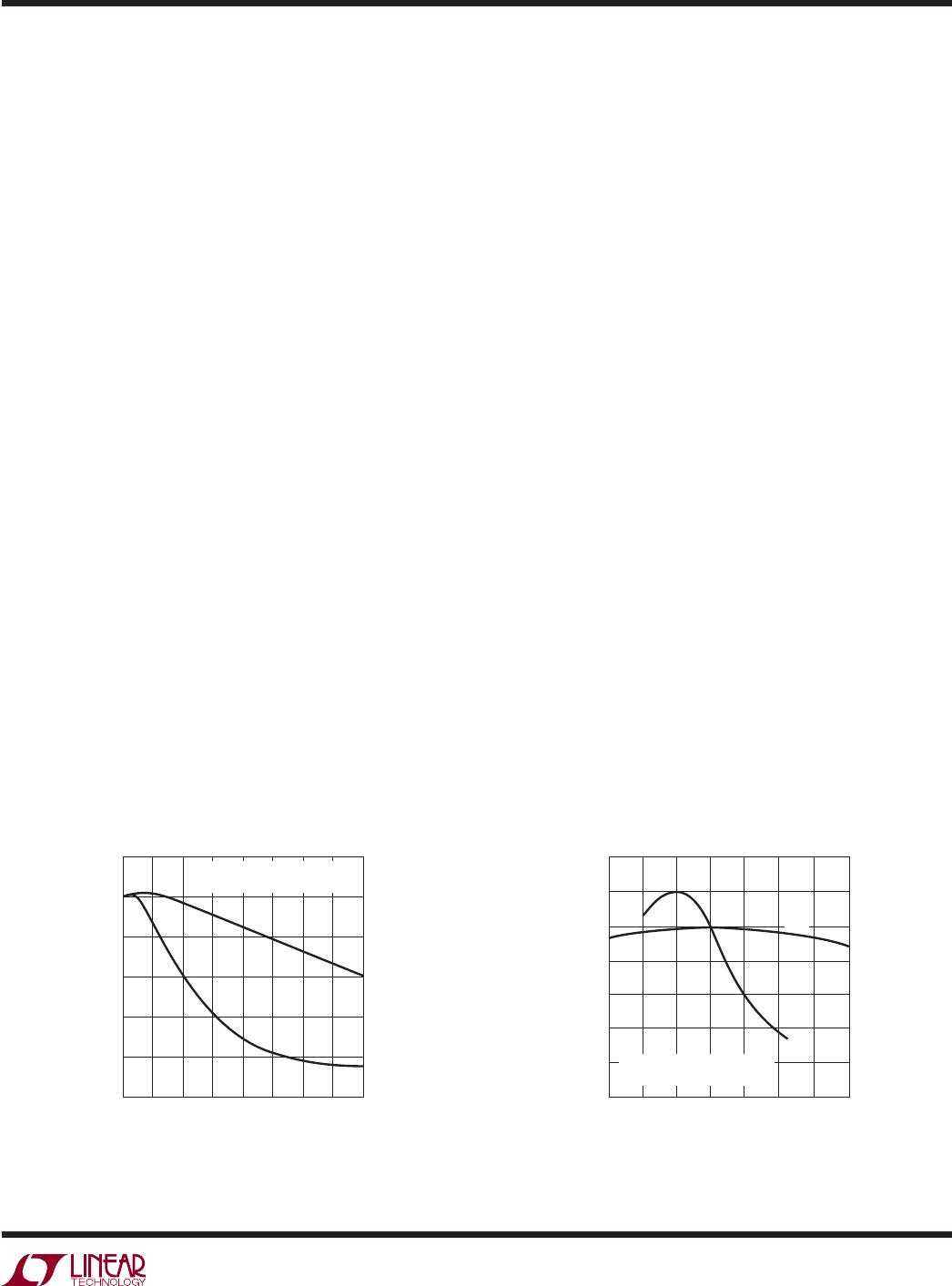

TEMPERATURE (°C)

–50

40

20

0

–20

–40

–60

–80

–100

25 75

3008 F04

–25 0

50 100 125

Y5V

CHANGE IN VALUE (%)

X5R

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10µF

Figure 3. Ceramic Capacitor DC Bias Characteristics

Figure 4. Ceramic Capacitor Temperature Characteristics

Because the ADJ pin is relatively high impedance (de-

pending on the resistor divider used), stray capacitances

at this pin should be minimized. Special attention should

be given to any stray capacitances that can couple ex-

ternal signals onto the ADJ pin, producing undesirable

output transients or ripple.

Extra care should be taken in assembly when using high

valued resistors. Small amounts of board contamination

can lead to signifi cant shifts in output voltage. Appropriate

post-assembly board cleaning measures should be

implemented to prevent board contamination. If the

board is to be subjected to humidity cycling or if board

cleaning measures cannot be guaranteed, consideration

should be given to using resistors an order of magnitude

smaller than in Table 1 to prevent contamination from

causing unwanted shifts in the output voltage. A fi xed

voltage option in the LT3008 series will not need these

special considerations.

Output Capacitance and Transient Response

The LT3008 is stable with a wide range of output capacitors.

The ESR of the output capacitor affects stability, most

notably with small capacitors. Use a minimum output

capacitor of 2.2µF with an ESR of 3 or less to prevent

oscillations. The LT3008 is a micropower device and output

load transient response is a function of output capacitance.

Larger values of output capacitance decrease the peak

deviations and provide improved transient response for

larger load current changes.

Give extra consideration to the use of ceramic capacitors.

Manufacturers make ceramic capacitors with a variety of

dielectrics, each with different behavior across temperature

and applied voltage. The most common dielectrics are

specifi ed with EIA temperature characteristic codes of

Z5U, Y5V, X5R and X7R. The Z5U and Y5V dielectrics

provide high C-V products in a small package at low cost,

but exhibit strong voltage and temperature coeffi cients as

shown in Figures 3 and 4. When used with a 5V regulator,

a 16V 10µF Y5V capacitor can exhibit an effective value

as low as 1µF to 2µF for the DC bias voltage applied and

over the operating temperature range. The X5R and

X7R dielectrics yield more stable characteristics and are

more suitable for use as the output capacitor. The X7R

type has better stability across temperature, while the

X5R is less expensive and is available in higher values.

One must still exercise care when using X5R and X7R

capacitors; the X5R and X7R codes only specify operating

temperature range and maximum capacitance change

over temperature. Capacitance change due to DC bias

with X5R and X7R capacitors is better than Y5V and Z5U

capacitors, but can still be signifi cant enough to drop

capacitor values below appropriate levels. Capacitor DC

bias characteristics tend to improve as component case

size increases, but expected capacitance at operating

voltage should be verifi ed.

Voltage and temperature coeffi cients are not the only

sources of problems. Some ceramic capacitors have a