M41ST85W Clock operation

Doc ID 7531 Rev 11 21/43

3.3 Calibrating the clock

The M41ST85W is driven by a quartz controlled oscillator with a nominal frequency of

32,768 Hz. The devices are tested not exceed +/–35 ppm (parts per million) oscillator

frequency error at 25

o

C, which equates to about +/–1.53 minutes per month. When the

Calibration circuit is properly employed, accuracy improves to better than ±2 ppm at 25°C.

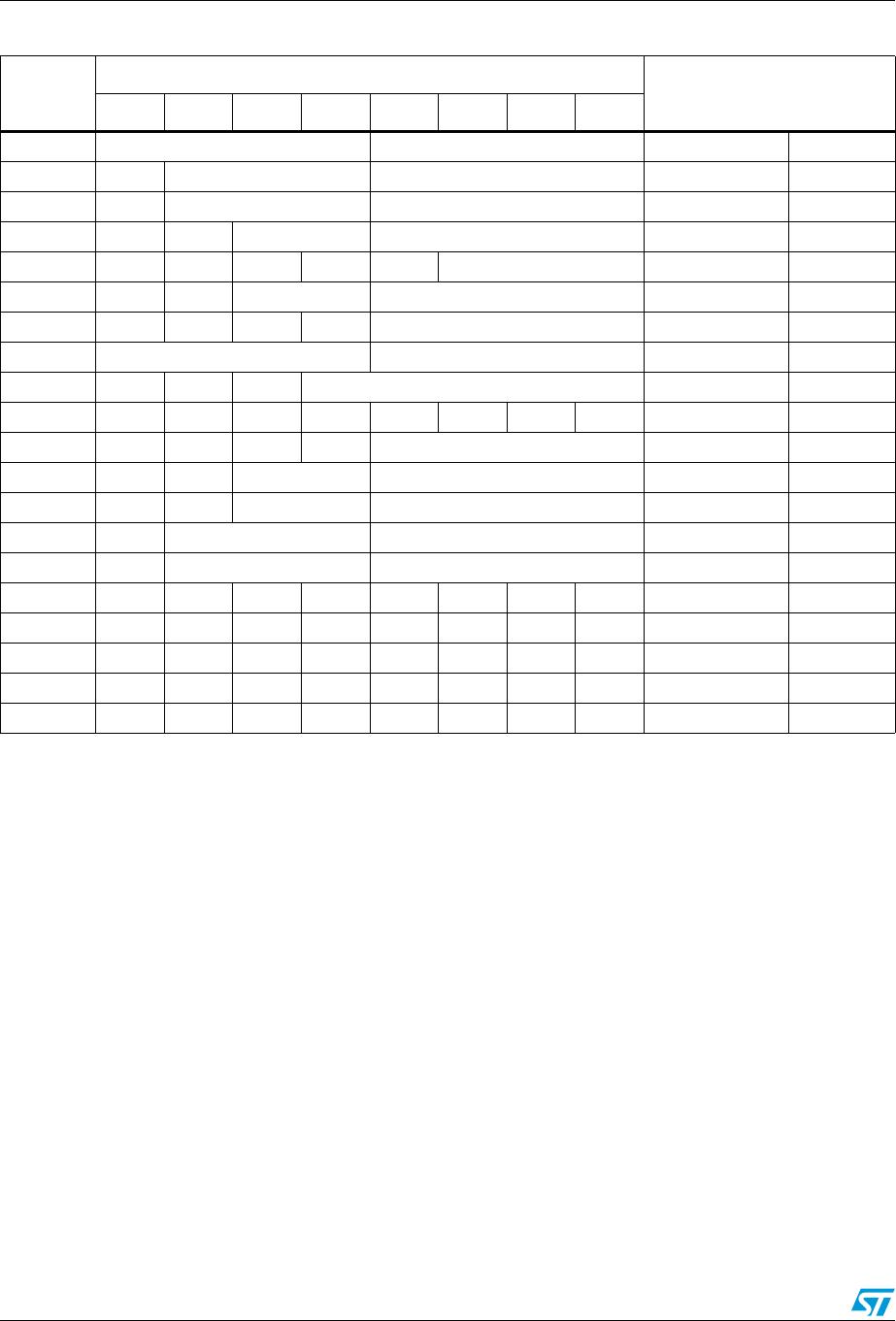

The oscillation rate of crystals changes with temperature (see Figure 13 on page 22).

Therefore, the M41ST85W design employs periodic counter correction. The calibration

circuit adds or subtracts counts from the oscillator divider circuit at the divide by 256 stage,

as shown in Figure 14 on page 22. The number of times pulses which are blanked

(subtracted, negative calibration) or split (added, positive calibration) depends upon the

value loaded into the five calibration bits found in the control register. Adding counts speeds

the clock up, subtracting counts slows the clock down.

The calibration bits occupy the five lower order bits (D4-D0) in the control register (08h).

These bits can be set to represent any value between 0 and 31 in binary form. Bit D5 is a

sign bit; '1' indicates positive calibration, '0' indicates negative calibration. Calibration occurs

within a 64 minute cycle. The first 62 minutes in the cycle may, once per minute, have one

second either shortened by 128 or lengthened by 256 oscillator cycles. If a binary '1' is

loaded into the register, only the first 2 minutes in the 64 minute cycle will be modified; if a

binary 6 is loaded, the first 12 will be affected, and so on.

Therefore, each calibration step has the effect of adding 512 or subtracting 256 oscillator

cycles for every 125,829,120 actual oscillator cycles, that is +4.068 or –2.034 ppm of

adjustment per calibration step in the calibration register. Assuming that the oscillator is

running at exactly 32,768 Hz, each of the 31 increments in the calibration byte would

represent +10.7 or –5.35 seconds per month which corresponds to a total range of +5.5 or

–2.75 minutes per month.

Two methods are available for ascertaining how much calibration a given M41ST85W may

require.

The first involves setting the clock, letting it run for a month and comparing it to a known

accurate reference and recording deviation over a fixed period of time. Calibration values,

including the number of seconds lost or gained in a given period, can be found in application

note AN934, “TIMEKEEPER

®

calibration.” This allows the designer to give the end user the

ability to calibrate the clock as the environment requires, even if the final product is

packaged in a non-user serviceable enclosure. The designer could provide a simple utility

that accesses the calibration byte.

The second approach is better suited to a manufacturing environment, and involves the use

of the IRQ

/FT/OUT pin. The pin will toggle at 512 Hz, when the stop bit (ST, D7 of 01h) is '0,'

the frequency test bit (FT, D6 of 08h) is '1,' the alarm flag enable bit (AFE, D7 of 0Ah) is '0,'

and the watchdog steering bit (WDS, D7 of 09h) is '1' or the watchdog register (09h = 0) is

reset.

Any deviation from 512 Hz indicates the degree and direction of oscillator frequency shift at

the test temperature. For example, a reading of 512.010124 Hz would indicate a +20 ppm

oscillator frequency error, requiring a –10 (XX001010) to be loaded into the calibration byte

for correction. Note that setting or changing the calibration byte does not affect the

frequency test output frequency.

The IRQ

/FT/OUT pin is an open drain output which requires a pull-up resistor to V

CC

for

proper operation. A 500 to 10 k resistor is recommended in order to control the rise time.

The FT bit is cleared on power-down.