General Capacitors

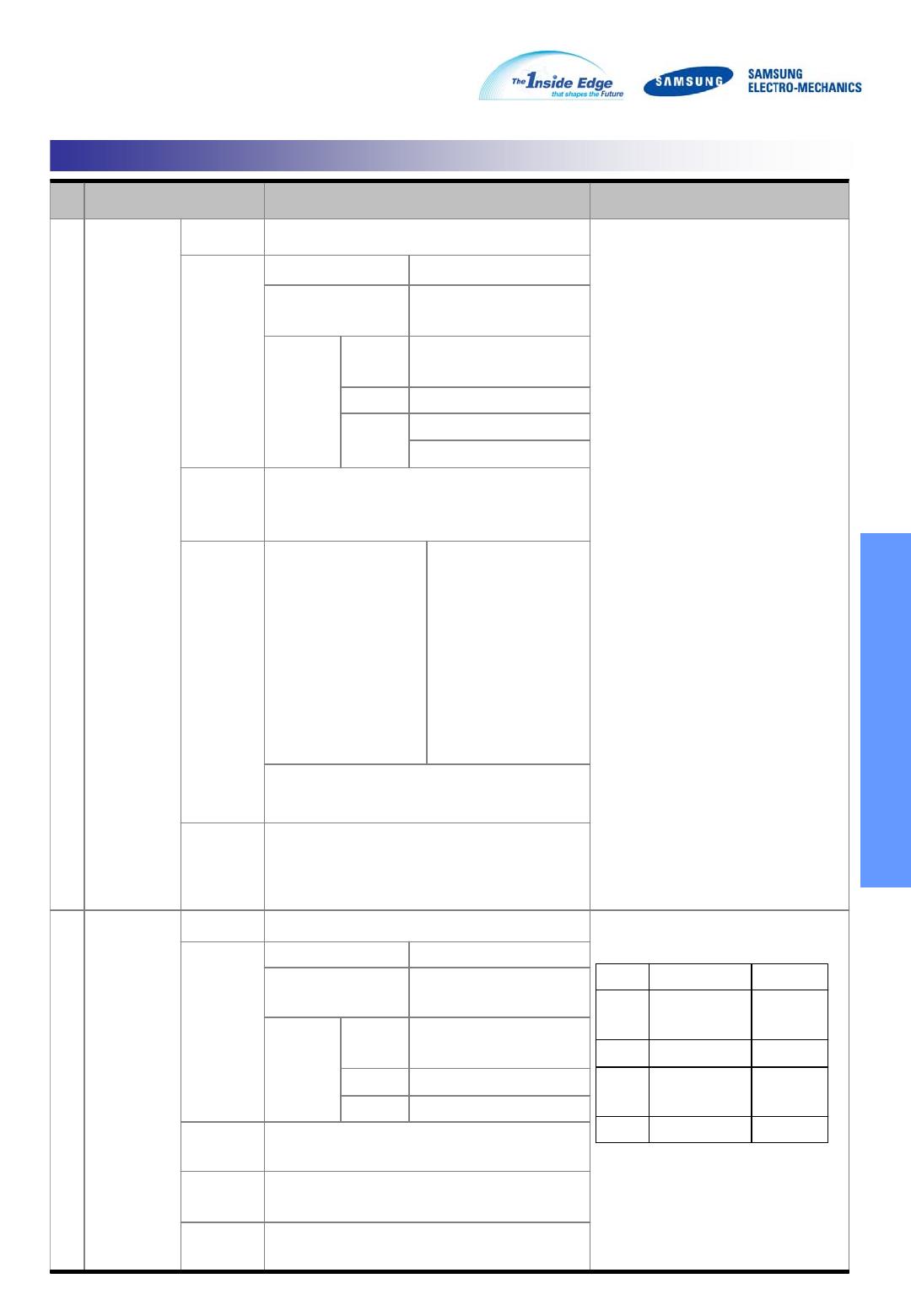

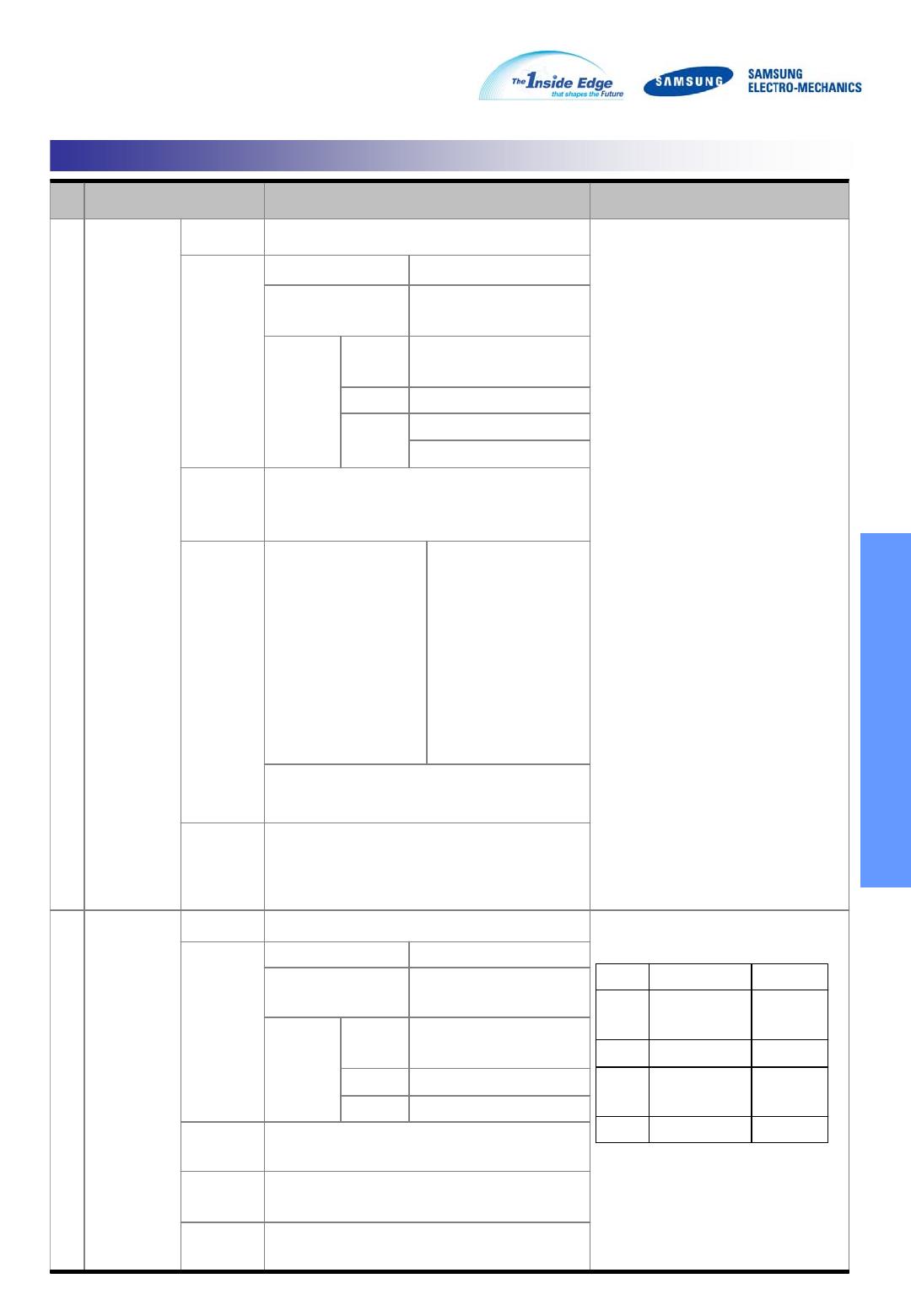

NO ITEM PERFORMANCE TEST CONDITION

15

High

Temperature

Resistance

Appearance No mechanical damage shall occur.

Applied Voltage : 200%* of the rated voltage

Temperature : max. operating temperature

Duration Time : 1000 +48/-0 Hr.

Charge/Discharge Current : 50

㎃

max.

* refer to table(3) : 150%/100% of the rated

voltage

Perform the initial measurement according to

Note1 for Class

Ⅱ

Perform the final measurement according to

Note2.

Capacitance

Characteristics Capacitance Change

Class

Ⅰ

Within ±3% or ±0.3

㎊

,

Whichever is larger

Class

Ⅱ

A(X5R)/

B(X7R)

Within ±12.5%

X(X6S) Within ±25%

F(Y5V)

Within ±30%

Within ±30%

Q

(Class

Ⅰ

)

Capacitance

≥

30

㎊

:Q

≥

350

10

≤

Capacitance <30

㎊

:Q

≥

275 + 2.5×C

Capacitance < 10

㎊

:Q

≥

200 +10×C (C: Capacitance)

Tan

δ

(Class

Ⅱ

)

1. Characteristic : A(X5R),

B(X7R)

0.05max

(16V and over)

0.075max (10V)

0.075max

(6.3V except Table 1)

0.125max*

(refer to Table 1)

2. Characteristic : F(Y5V)

0.075max

(25V and over)

0.1max(16V, C<1.0

㎌

)

0.125max(16V, C

≥

1.0

㎌

)

0.15max ( 10V)

0.195max (6.3V)

X(X6S) 0.11max (6.3V and below)

Insulation

Resistance

1,000

㏁

or 50

㏁

·

㎌

whichever is smaller.

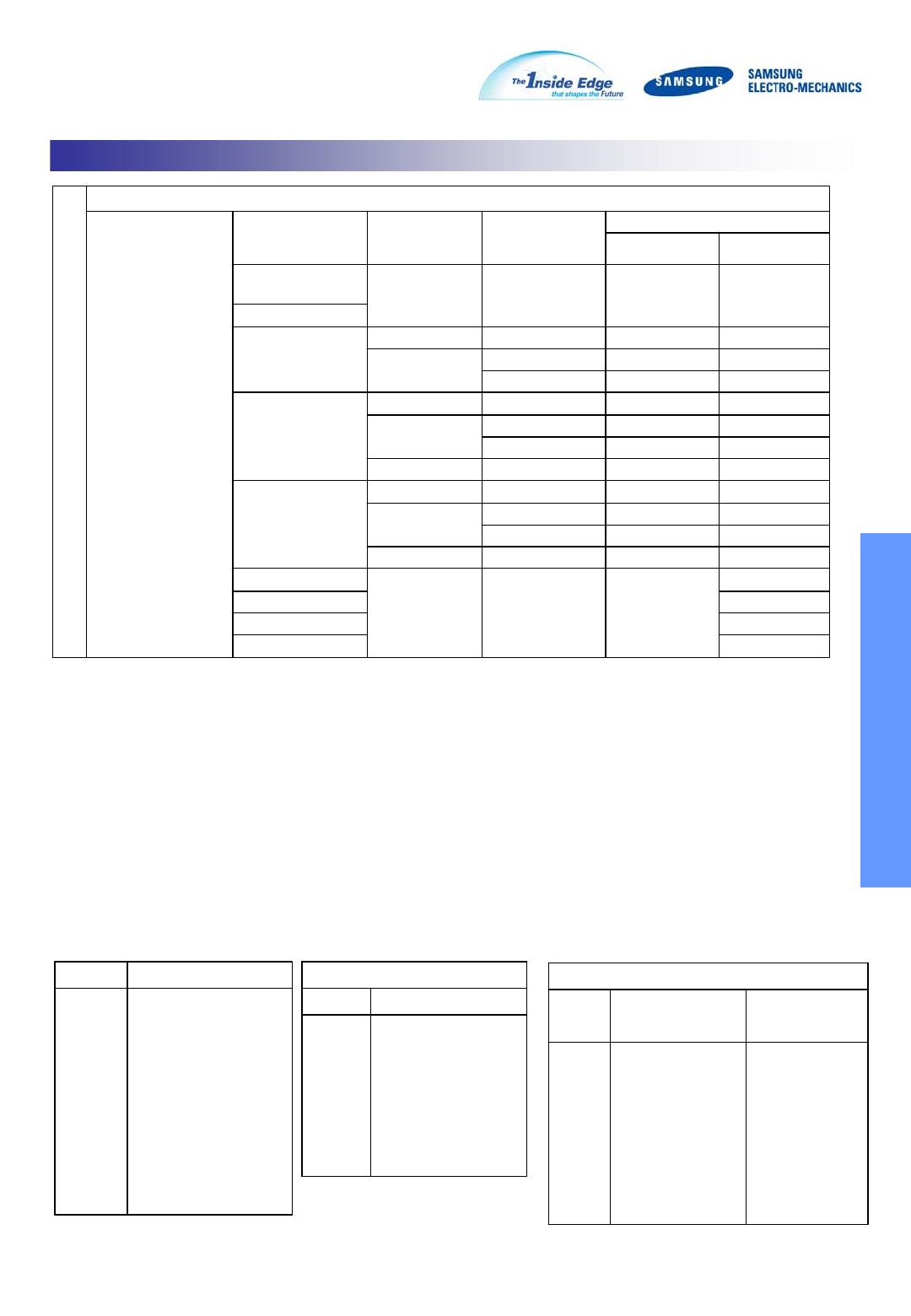

16

Temperature

Cycle

Appearance No mechanical damage shall occur.

Capacitor shall be subjected to 5 cycles.

Condition for 1 cycle :

Step Temp.(

℃

) Time(min.)

1

Min. operating

temp.+0/-3

30

225 2~3

3

Max. operating

temp.+3/-0

30

425 2~3

Leave the capacitor in ambient condition

for specified time* before measurement

*24±2hours(Class

Ⅰ

)

24 ± 2 hours (Class

Ⅱ

)

Capacitance

Characteristics Capacitance Change

Class

Ⅰ

Within ±2.5% or ±0.25

㎊

Whichever is larger

Class

Ⅱ

A(X5R)/

B(X7R)/

Within ±7.5%

X(X6S) Within ±15%

F(Y5V) Within ±20%

Q

(Class

Ⅰ

)

Within the specified initial value

Tan

δ

(Class

Ⅱ

)

Within the specified initial value

Insulation

Resistance

Within the specified initial value

RELIABILTY TEST CONDITION