General Capacitors

NO

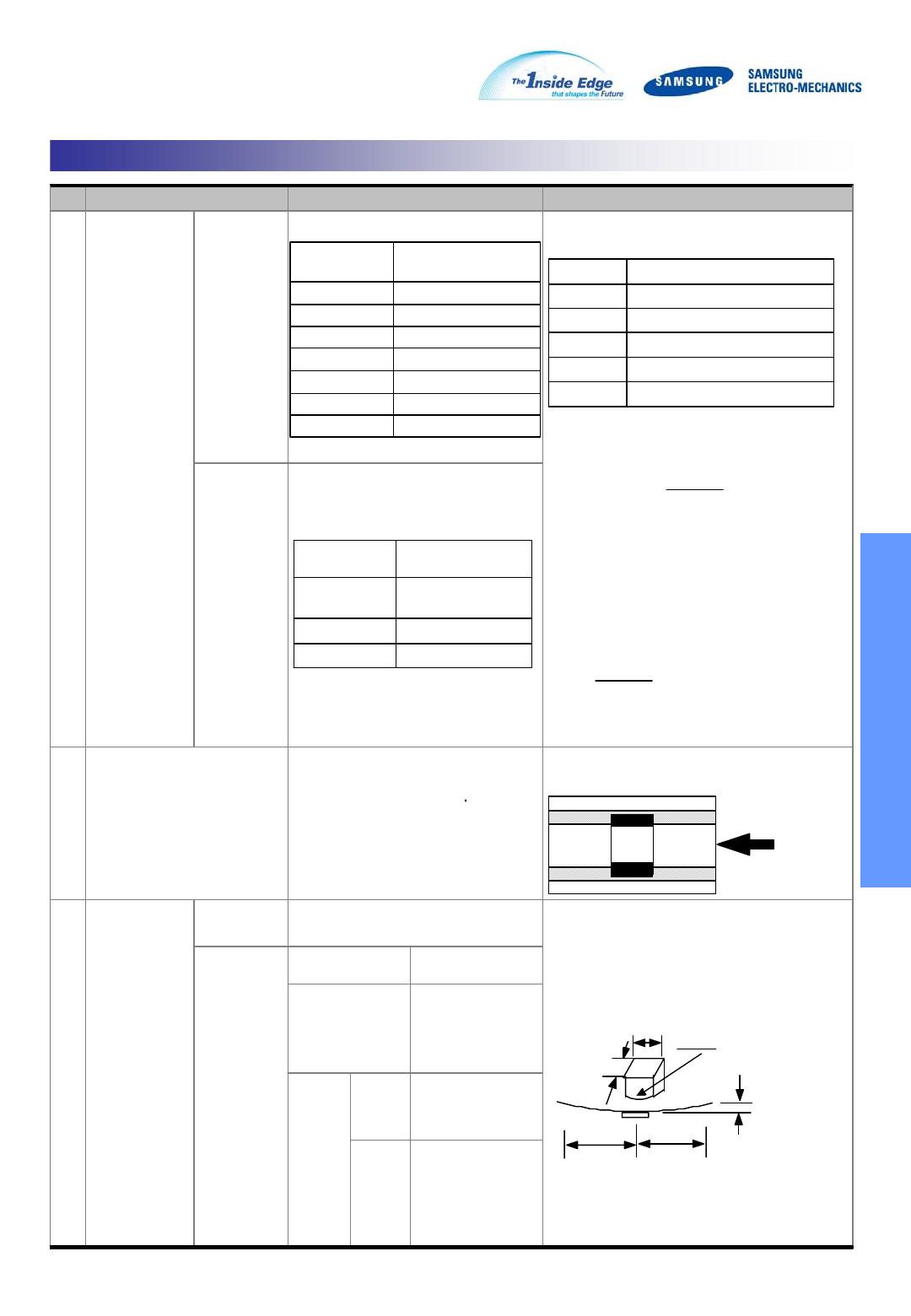

ITEM PERFORMANCE TEST CONDITION

10

Solderability

More Than 75% of the terminal surface is to

be soldered newly, So metal part does not

come out or dissolve

11

Resistance to

Soldering heat

Apperance No mechanical damage shall occur. Solder Temperature : 270±5

℃

Dip Time : 10±1 sec.

Each termination shall be fully immersed and

preheated as below :

Leave the capacitor in ambient condition for

specified time* before measurement

*24±2hours(Class

Ⅰ

)

24 ± 2 hours (Class

Ⅱ

)

Capacitance

Characteristics Capacitance Change

Class

Ⅰ

Within ±2.5% or

±0.25

㎊

whichever is

larger

Class

Ⅱ

A(X5R)/

B(X7R)

Within ±7.5%

X(X6S) Within ±15%

F Within ±20%

Q

(Class

Ⅰ

)

Capacitance

≥

30

㎊

:Q

≥

1000

<30

㎊

:Q

≥

400+20×C

(C: Capacitance)

Tan

δ

(Class

Ⅱ

)

Within the specified initial value

Insulation

Resistance

Within the specified initial value

Withstanding

Voltage

Within the specified initial value

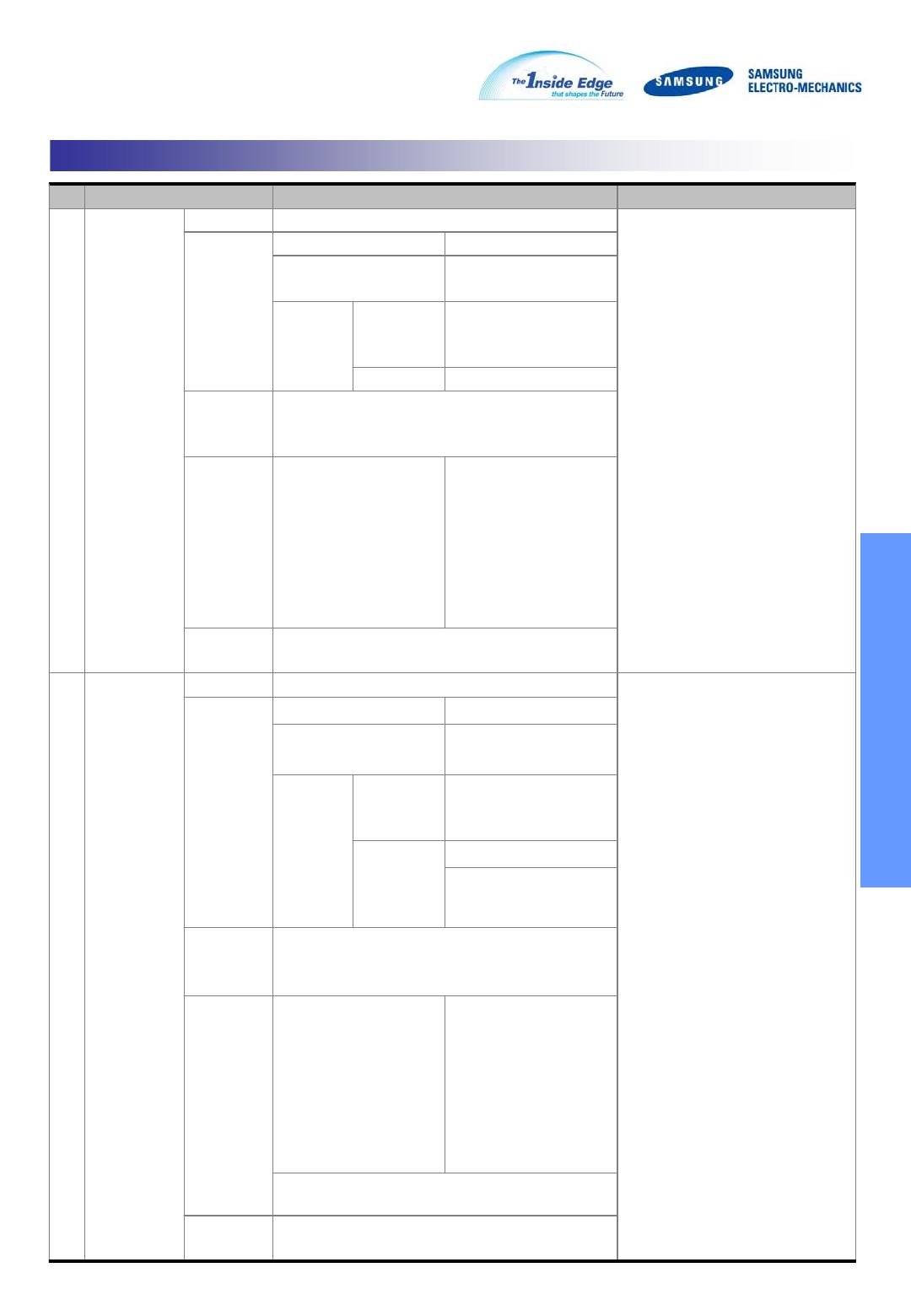

12

Vibration

Test

Appearance No mechanical damage shall occur.

The capacitor shall be subjected to a

Harmonic Motion having a total amplitude of

1.5mm changing frequency from 10Hz to 55Hz

and back to 10Hz In 1 min.

Repeat this for 2hours each in 3 mutually

perpendicular directions

Capacitance

Characteristics Capacitance Change

Class

Ⅰ

Within ±2.5% or

±0.25

㎊

whichever is

larger

Class

Ⅱ

A(X5R)/

B(X7R)

Within ±5%

X(X6S) Within ±10%

F(Y5V) Within ±20%

Q

(Class

Ⅰ

)

Within the specified initial value

Tan

δ

(Class

Ⅱ

)

Within the specified initial value

Insulation

Resistance

Within the specified initial value

STEP TEMP.(

℃

) TIME(SEC.)

1 80~100 60

2 150~180 60

Solder Sn-3Ag-0.5Cu 63Sn-37Pb

Solder

Temp.

245±5

℃

235±5

℃

Flux RMA Type

Dip Time 3±0.3 sec. 5±0.5 sec.

Pre-heating at 80~120

℃

for 10~30 sec.

RELIABILTY TEST CONDITION