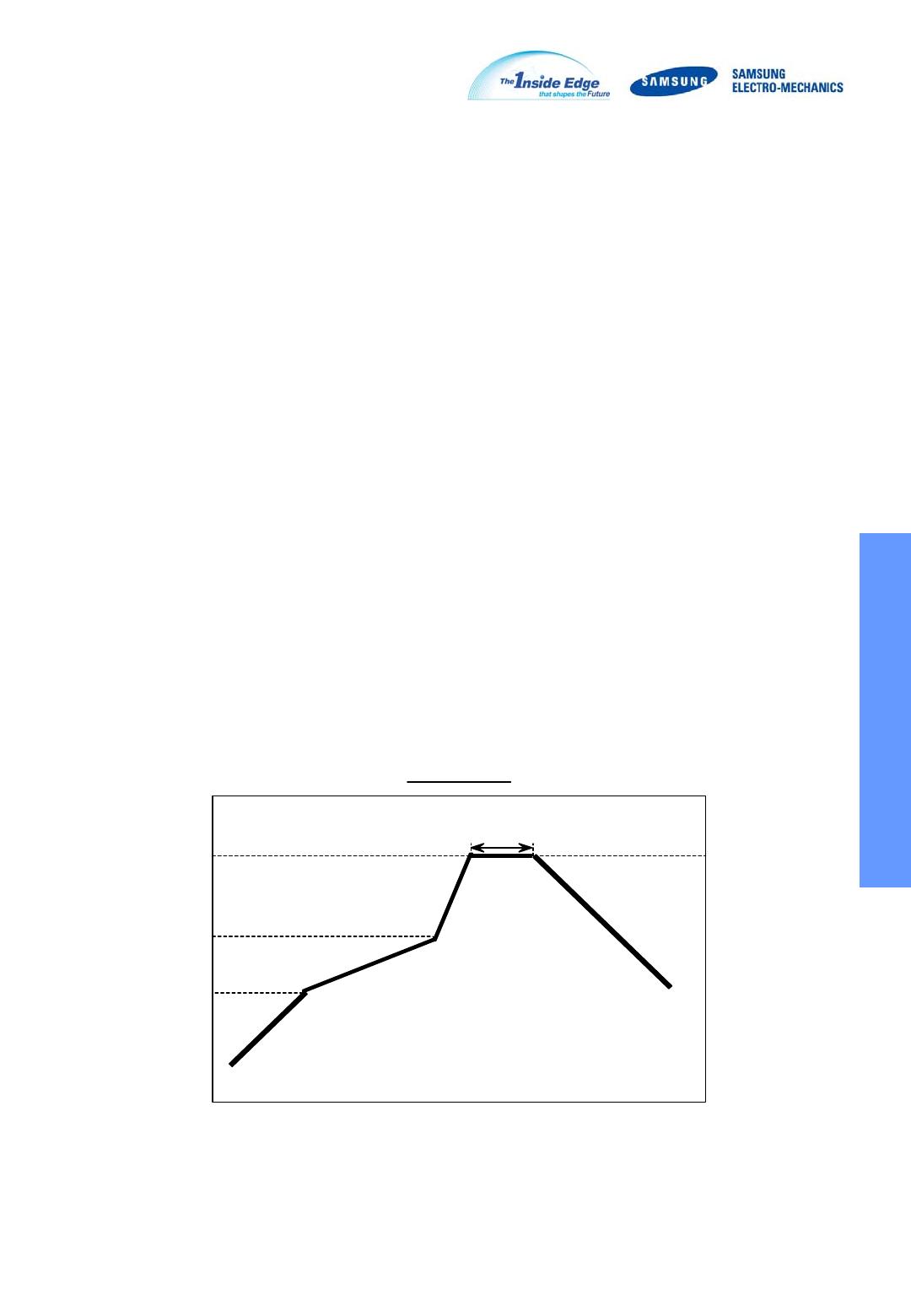

Pre-heating

Gradual cooling

in the air

Soldering

Temp.(℃ )

260+0/-5℃

10sec.max.

Time(sec)

Reflow

200℃

150℃

General Capacitors

▶ Cooling

Natural cooling using air is recommended. If the chips are dipped into solvent for cleaning, the

temperature difference(△T) must be less than 100℃

▶ Cleaning

If rosin flux is used, cleaning usually is unnecessary. When strongly activated flux is used, chlorine in

the flux may dissolve into some types of cleaning fluids, thereby affecting the chip capacitors. This

means that the cleaning fluid must be carefully selected, and should always be new.

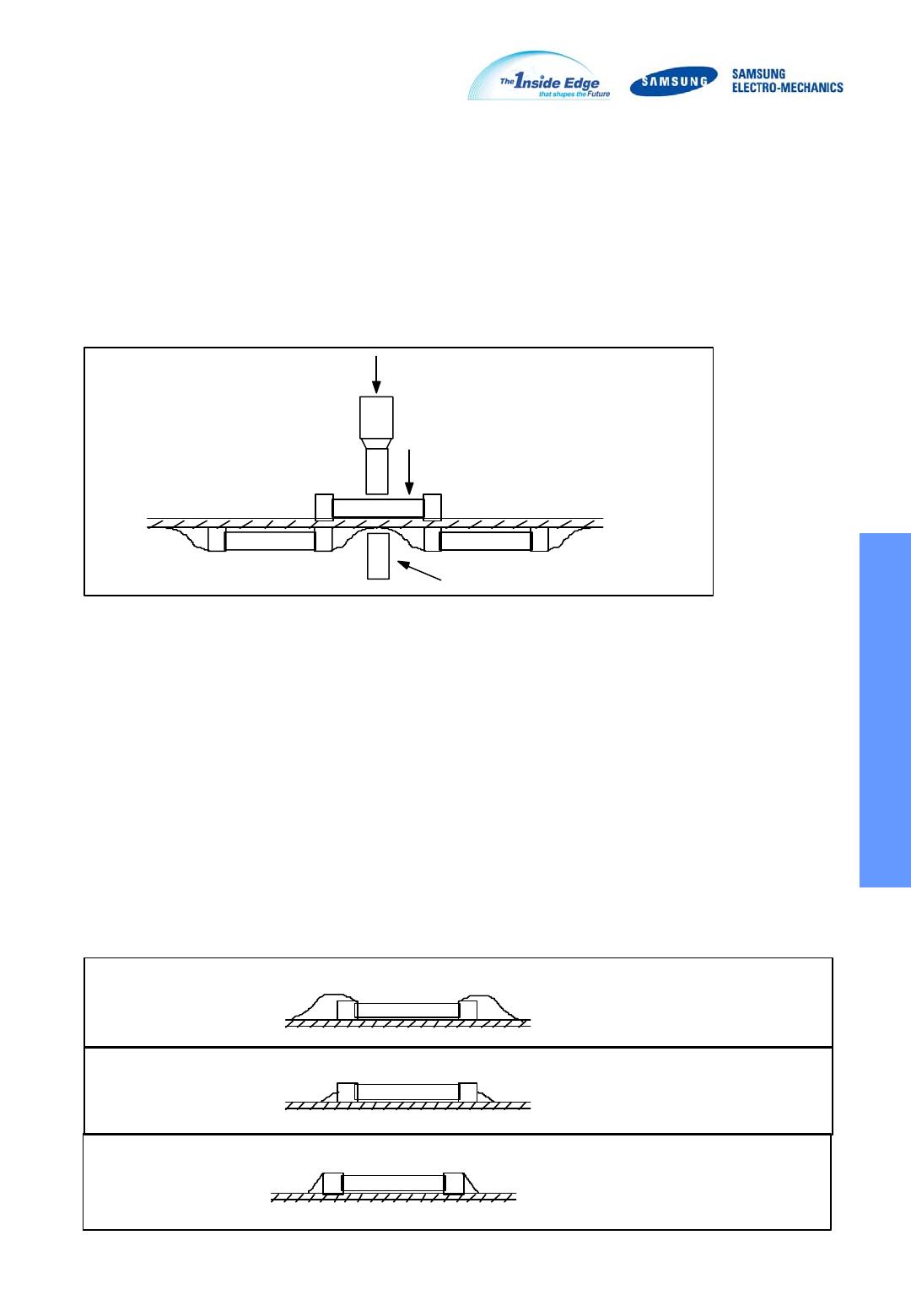

▶ Notes for Separating Multiple, Shared PC Boards.

A multi-PC board is separated into many individual circuit boards after soldering has been completed.

If the board is bent or distorted at the time of separation, cracks may occur in the chip capacitors.

Carefully choose a separation method that minimizes the bending often circuit board.

▶ Recommended Soldering Profile