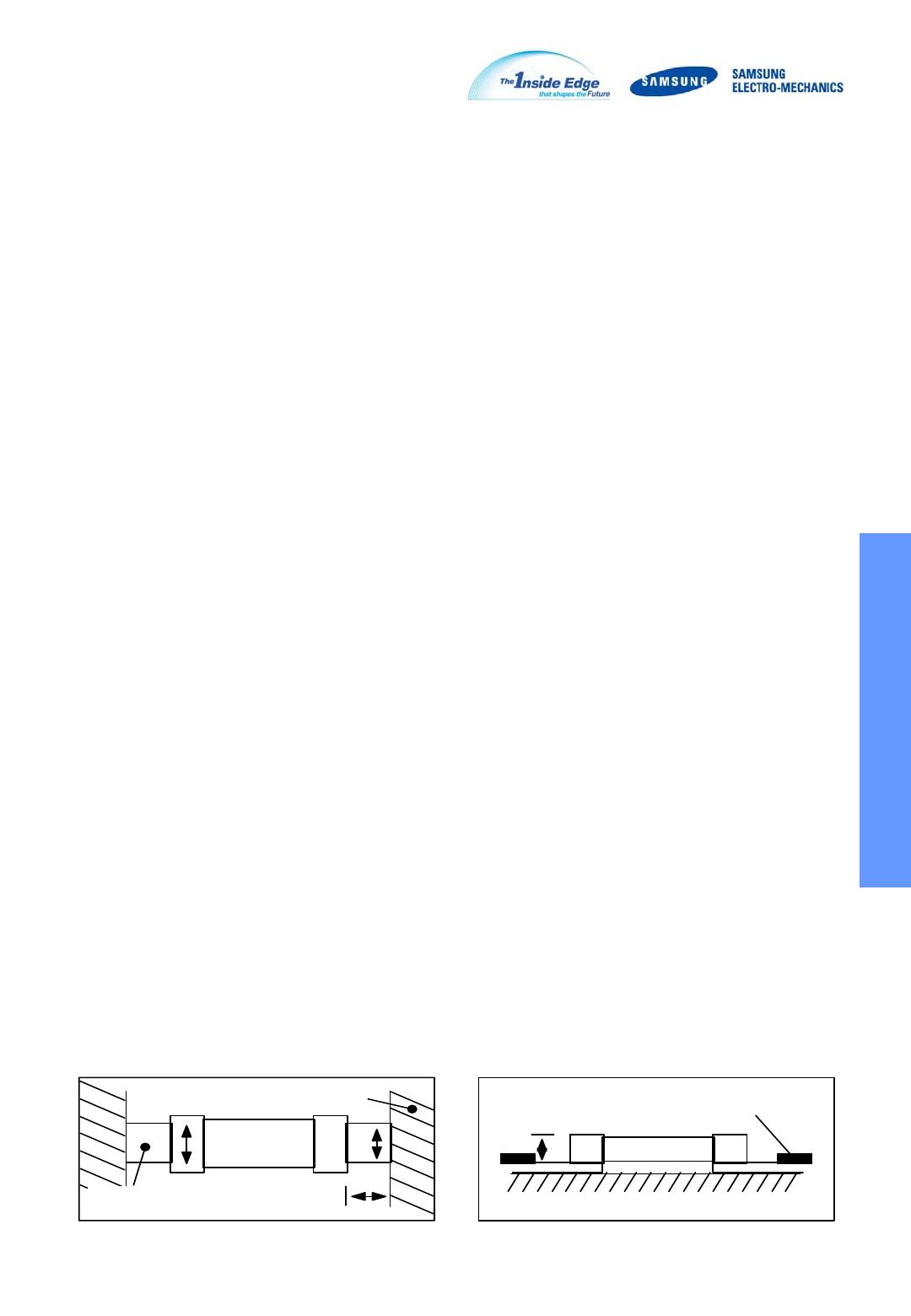

W b

a

Solder

Land

Solder Resist

2/3W < b < W

T

Solder Resist

2/3T < a < T

General Capacitors

● STORAGE CONDITION

▶ Storage Environment

The electrical characteristics of MLCCs were degraded by the environment of high temperature or

humidity. Therefore, the MLCCs shall be stored in the ambient temperature and the relative humidity

of less than 40℃ and 70%, respectively.

Guaranteed storage period is within 6 months from the outgoing date of delivery.

▶ Corrosive Gases

Since the solderability of the end termination in MLCC was degraded by a chemical atmosphere

such as chlorine, acid or sulfide gases, MLCCs must be avoid from these gases.

▶ Temperature Fluctuations

Since dew condensation may occur by the differences in temperature when the MLCCs are taken

out of storage, it is important to maintain the temperature-controlled environment

.

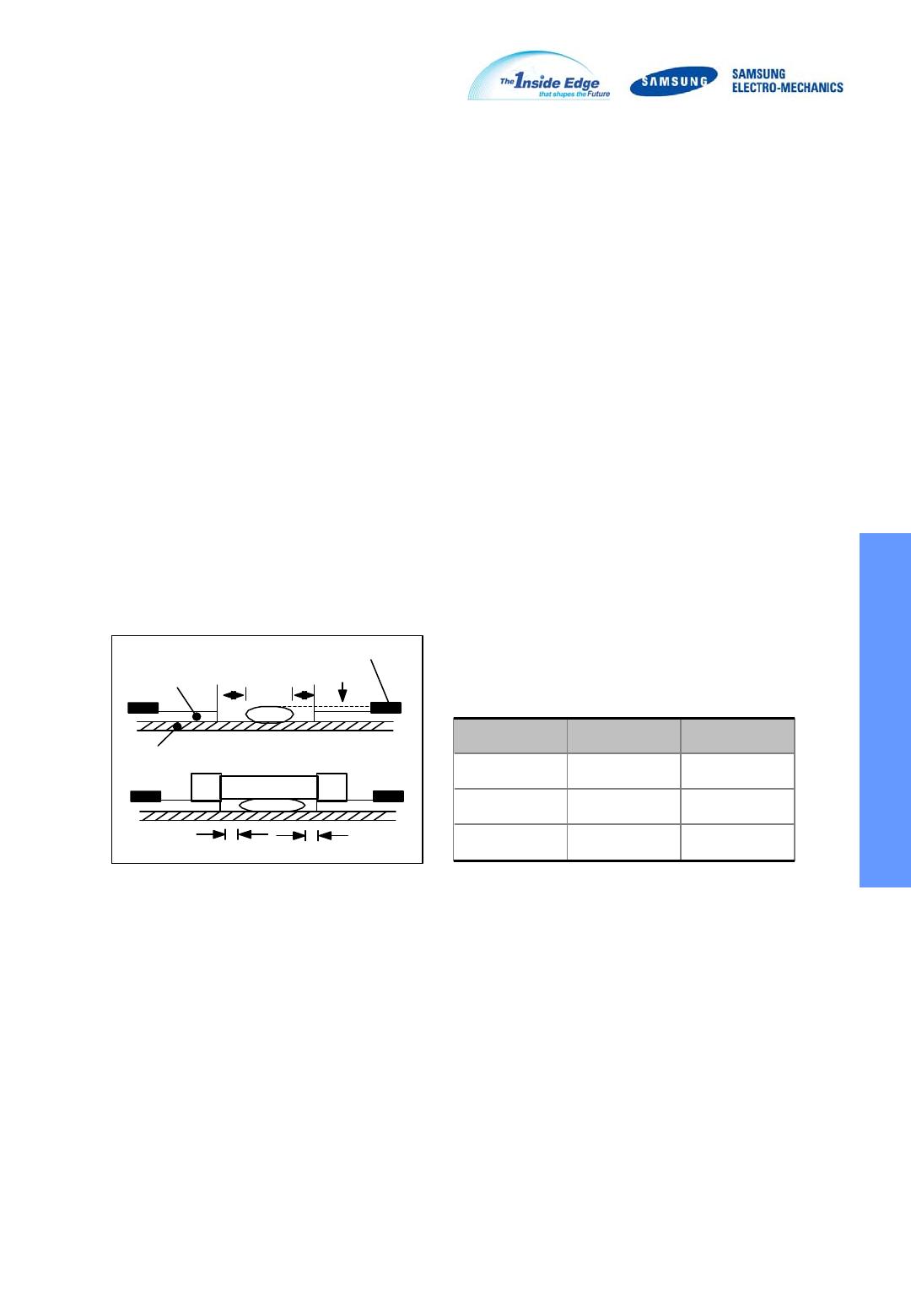

● DESIGN OF LAND PATTERN

When designing printed circuit boards, the shape and size of the lands must allow for the proper

amount of solder on the capacitor.

The amount of solder at the end terminations has a direct effect on the crack.

The crack in MLCC will be easily occurred by the tensile stress which was due to too much amount

of solder. In contrast, if too little solder is applied, the termination strength will be insufficiently.

Use the following illustrations as guidelines for proper land design.

Recommendation of Land Shape and Size.