23

Intersil products are manufactured, assembled and tested utilizing ISO9001 quality systems as noted

in the quality certifications found at www.intersil.com/en/support/qualandreliability.html

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time

without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be

accurate and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

For additional products, see www.intersil.com/en/products.html

82C54

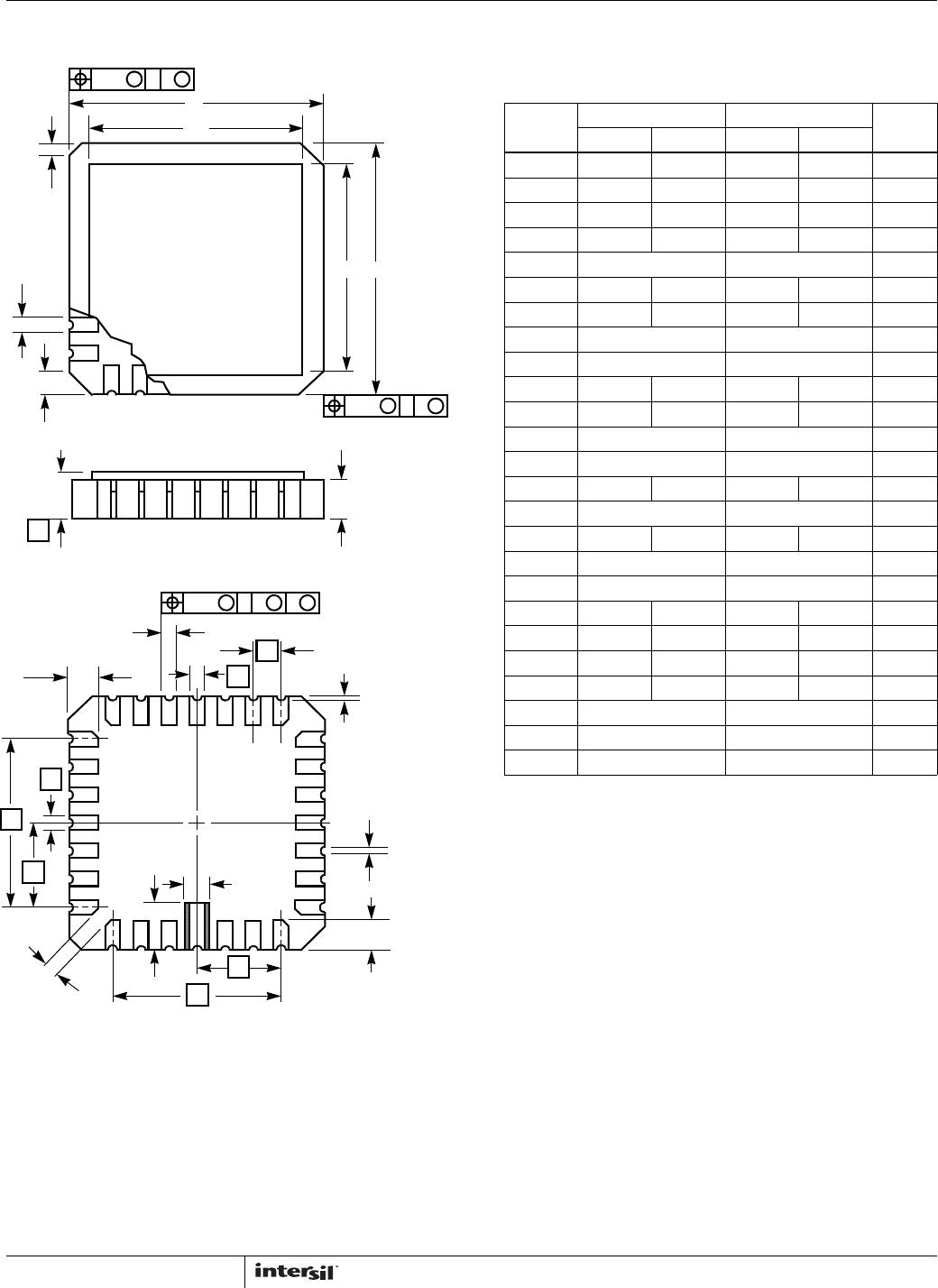

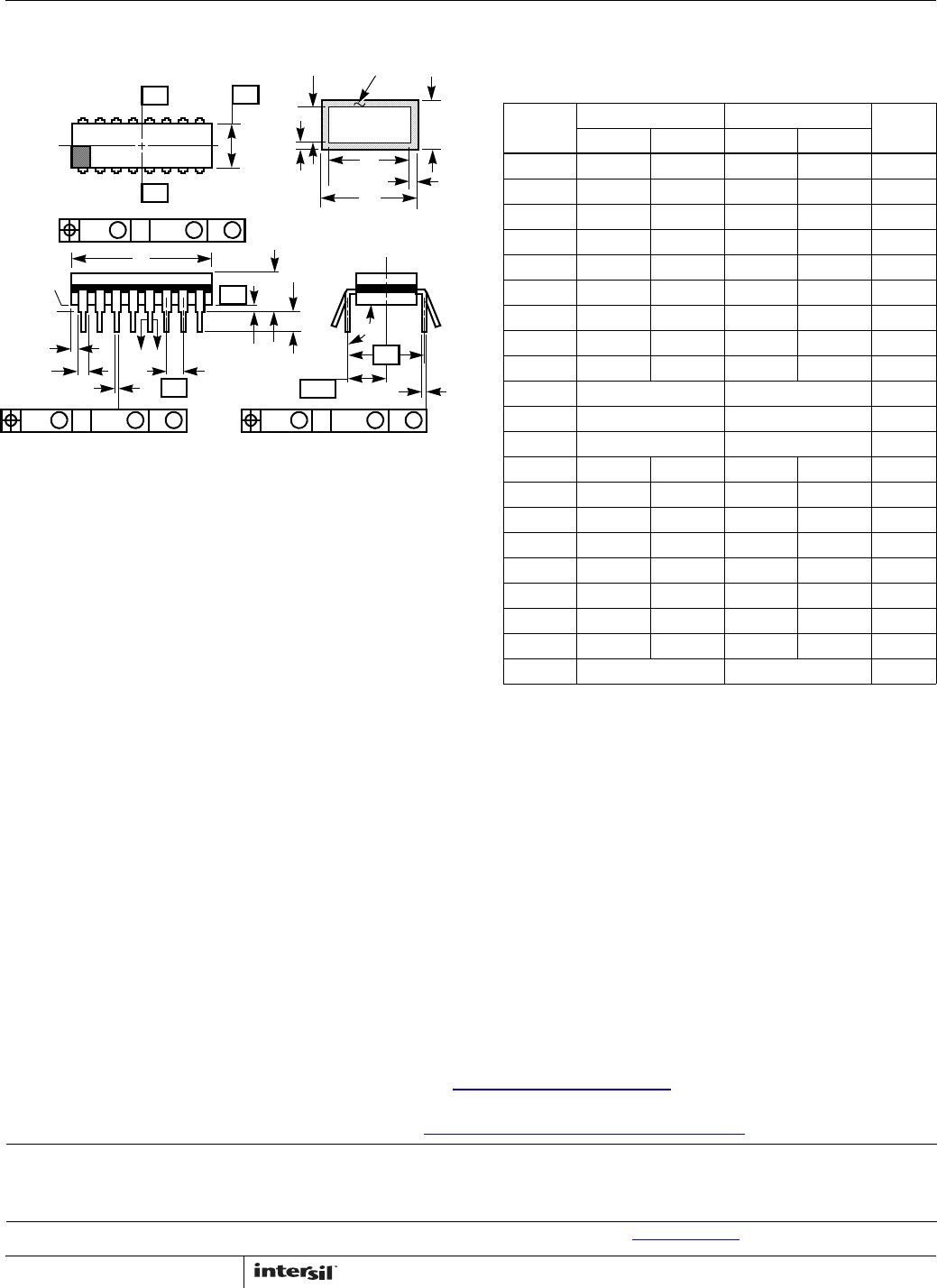

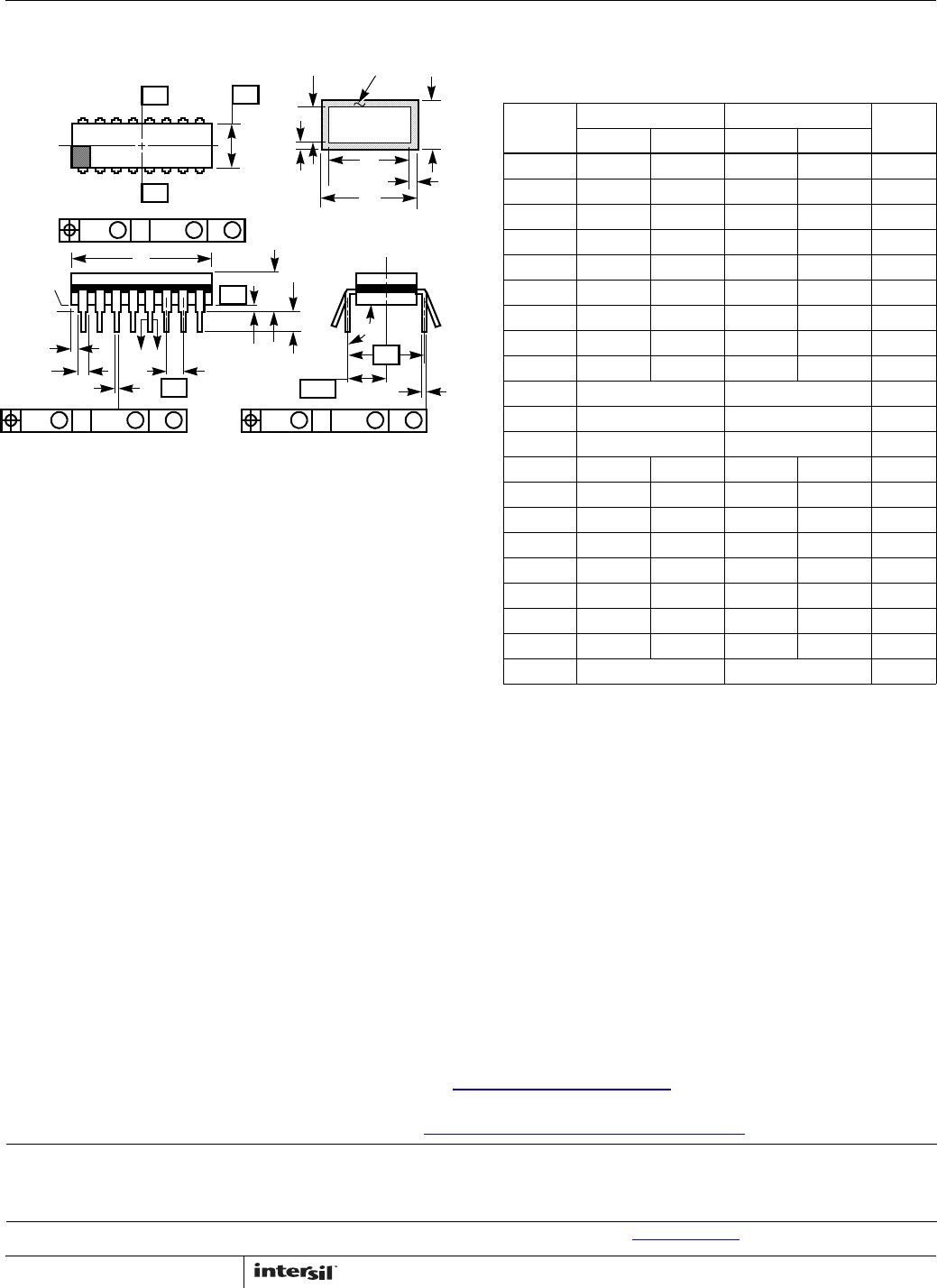

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

NOTES:

1. Index area: A notch or a pin one identification mark shall be locat-

ed adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

bbb C A - B

S

c

Q

L

A

SEATING

BASE

D

PLANE

PLANE

-D-

-A-

-C-

-B-

D

E

S1

b2

b

A

e

M

c1

b1

(c)

(b)

SECTION A-A

BASE

LEAD FINISH

METAL

eA/2

A

M

S

S

ccc C A - B

M

D

S

S

aaa CA - B

M

D

S

S

eA

F24.6 MIL-STD-1835 GDIP1-T24 (D-3, CONFIGURATION A)

24 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

SYMBOL

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

A - 0.225 - 5.72 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 -

b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 1.290 - 32.77 5

E 0.500 0.610 12.70 15.49 5

e 0.100 BSC 2.54 BSC -

eA 0.600 BSC 15.24 BSC -

eA/2 0.300 BSC 7.62 BSC -

L 0.120 0.200 3.05 5.08 -

Q 0.015 0.075 0.38 1.91 6

S1 0.005 - 0.13 - 7

90

o

105

o

90

o

105

o

-

aaa - 0.015 - 0.38 -

bbb - 0.030 - 0.76 -

ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2, 3

N24 248

Rev. 0 4/94