10

LTC1435

APPLICATIONS INFORMATION

WUU

U

where δ is the temperature dependency of R

DS(ON)

and k

is a constant inversely related to the gate drive current.

Both MOSFETs have I

2

R losses while the topside

N-channel equation includes an additional term for tran-

sition losses, which are highest at high input voltages.

For V

IN

< 20V the high current efficiency generally im-

proves with larger MOSFETs, while for V

IN

> 20V the

transition losses rapidly increase to the point that the use

of a higher R

DS(ON)

device with lower C

RSS

actual pro-

vides higher efficiency. The synchronous MOSFET losses

are greatest at high input voltage or during a short circuit

when the duty cycle in this switch is nearly 100%. Refer

to the Foldback Current Limiting section for further

applications information.

The term (1 + δ) is generally given for a MOSFET in the

form of a normalized R

DS(ON)

vs Temperature curve, but

δ = 0.005/°C can be used as an approximation for low

voltage MOSFETs. C

RSS

is usually specified in the MOSFET

characteristics. The constant k = 2.5 can be used to

estimate the contributions of the two terms in the main

switch dissipation equation.

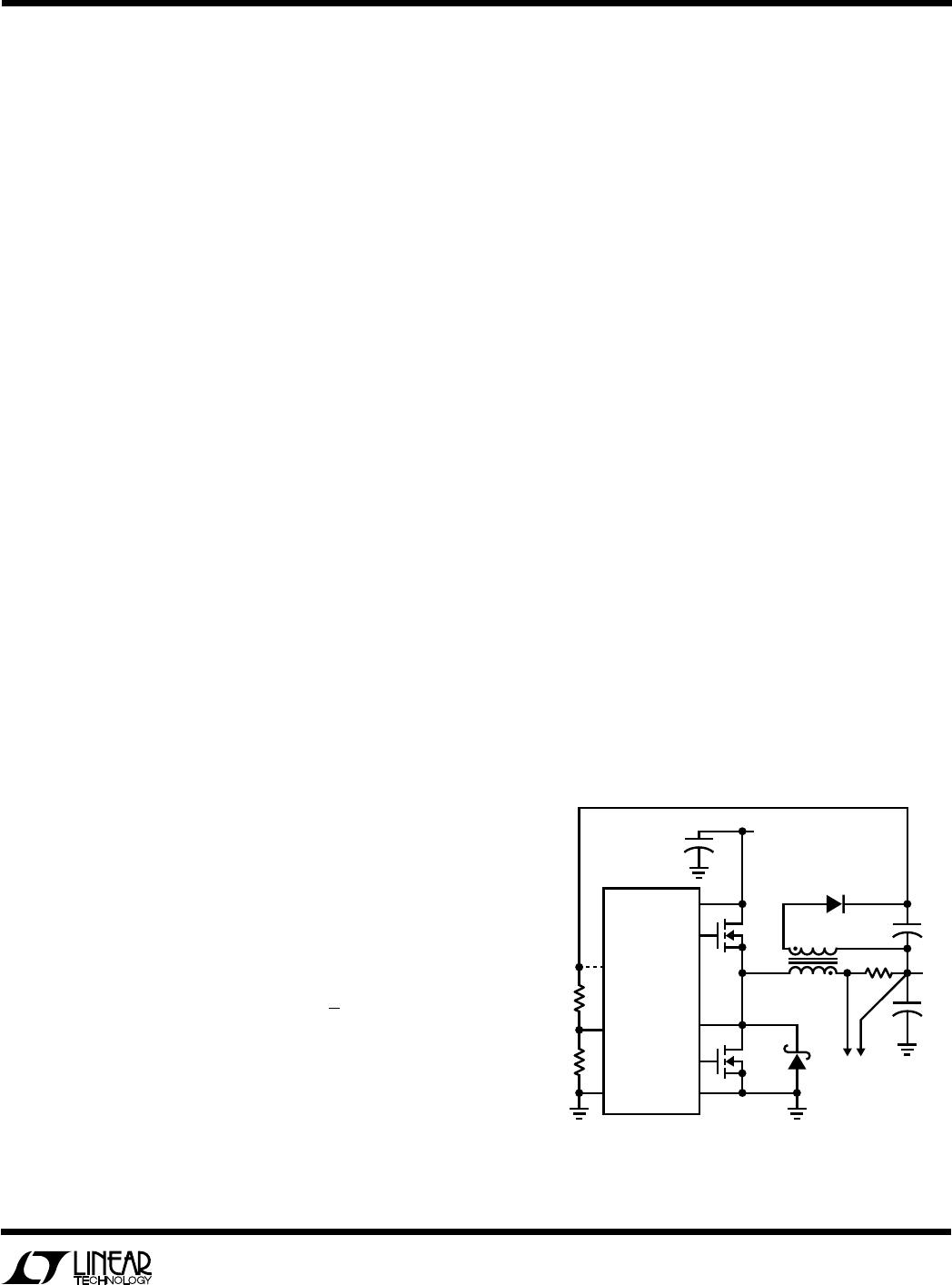

The Schottky diode D1 shown in Figure 1 conducts during

the dead-time between the conduction of the two large

power MOSFETs. This prevents the body diode of the

bottom MOSFET from turning on and storing charge

during the dead-time, which could cost as much as 1% in

efficiency. A 1A Schottky is generally a good size for 3A

regulators.

C

IN

and C

OUT

Selection

In continuous mode, the source current of the top

N-channel MOSFET is a square wave of duty cycle V

OUT

/

V

IN

. To prevent large voltage transients, a low ESR input

capacitor sized for the maximum RMS current must be

used. The maximum RMS capacitor current is given by:

C required

IN

II

VVV

V

RMS MAX

OUT IN OUT

IN

≈

−

()

[]

12/

This formula has a maximum at V

IN

= 2V

OUT

, where

I

RMS

= I

OUT

/2. This simple worst-case condition is com-

monly used for design because even significant deviations

do not offer much relief. Note that capacitor manufacturer’s

ripple current ratings are often based on only 2000 hours

of life. This makes it advisable to further derate the

capacitor or to choose a capacitor rated at a higher

temperature than required. Several capacitors may also be

paralleled to meet size or height requirements in the

design. Always consult the manufacturer if there is any

question.

The selection of C

OUT

is driven by the required effective

series resistance (ESR). Typically, once the ESR require-

ment is satisfied the capacitance is adequate for filtering.

The output ripple (∆V

OUT

) is approximated by:

∆∆V I ESR

fC

OUT L

OUT

≈+

1

4

where f = operating frequency, C

OUT

= output capacitance

and ∆I

L

= ripple current in the inductor. The output ripple

is highest at maximum input voltage since ∆I

L

increases

with input voltage. With ∆I

L

= 0.4I

OUT(MAX)

the output

ripple will be less than 100mV at max V

IN

assuming:

C

OUT

required ESR < 2R

SENSE

Manufacturers such as Nichicon, United Chemicon and

Sanyo should be considered for high performance through-

hole capacitors. The OS-CON semiconductor dielectric

capacitor available from Sanyo has the lowest ESR(size)

product of any aluminum electrolytic at a somewhat

higher price. Once the ESR requirement for C

OUT

has been

met, the RMS current rating generally far exceeds the

I

RIPPLE(P-P)

requirement.

In surface mount applications multiple capacitors may

have to be paralleled to meet the ESR or RMS current

handling requirements of the application. Aluminum elec-

trolytic and dry tantalum capacitors are both available in

surface mount configurations. In the case of tantalum, it is

critical that the capacitors are surge tested for use in

switching power supplies. An excellent choice is the AVX

TPS series of surface mount tantalum, available in case

heights ranging from 2mm to 4mm. Other capacitor types

include Sanyo OS-CON, Nichicon PL series and Sprague

593D and 595D series. Consult the manufacturer for other

specific recommendations.