LT3480

11

3480fe

For more information www.linear.com/LT3480

APPLICATIONS INFORMATION

where V

D

is the voltage drop of the catch diode (~0.4V),

V

IN(MAX)

is the maximum input voltage, V

OUT

is the output

voltage, f

SW

is the switching frequency (set by RT), and L

is in the inductor value.

The inductor’s RMS current rating must be greater than the

maximum load current and its saturation current should be

about 30% higher. For robust operation in fault conditions

(start-up or short circuit) and high input voltage (>30V),

the saturation current should be above 3.5A. To keep the

efficiency high, the series resistance (DCR) should be less

than 0.1

, and the core material should be intended for

high frequency applications. Table 1 lists several vendors

and suitable types.

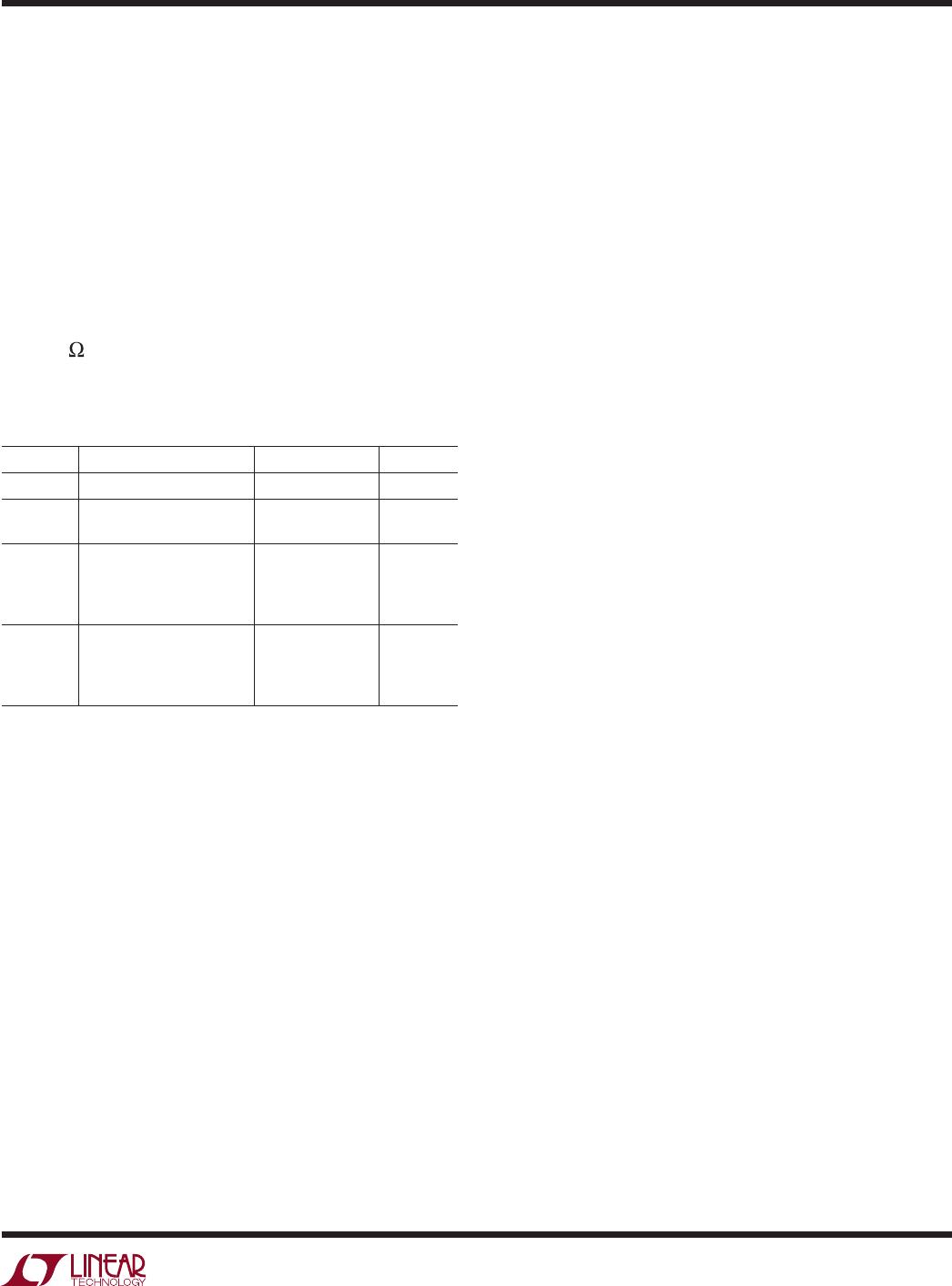

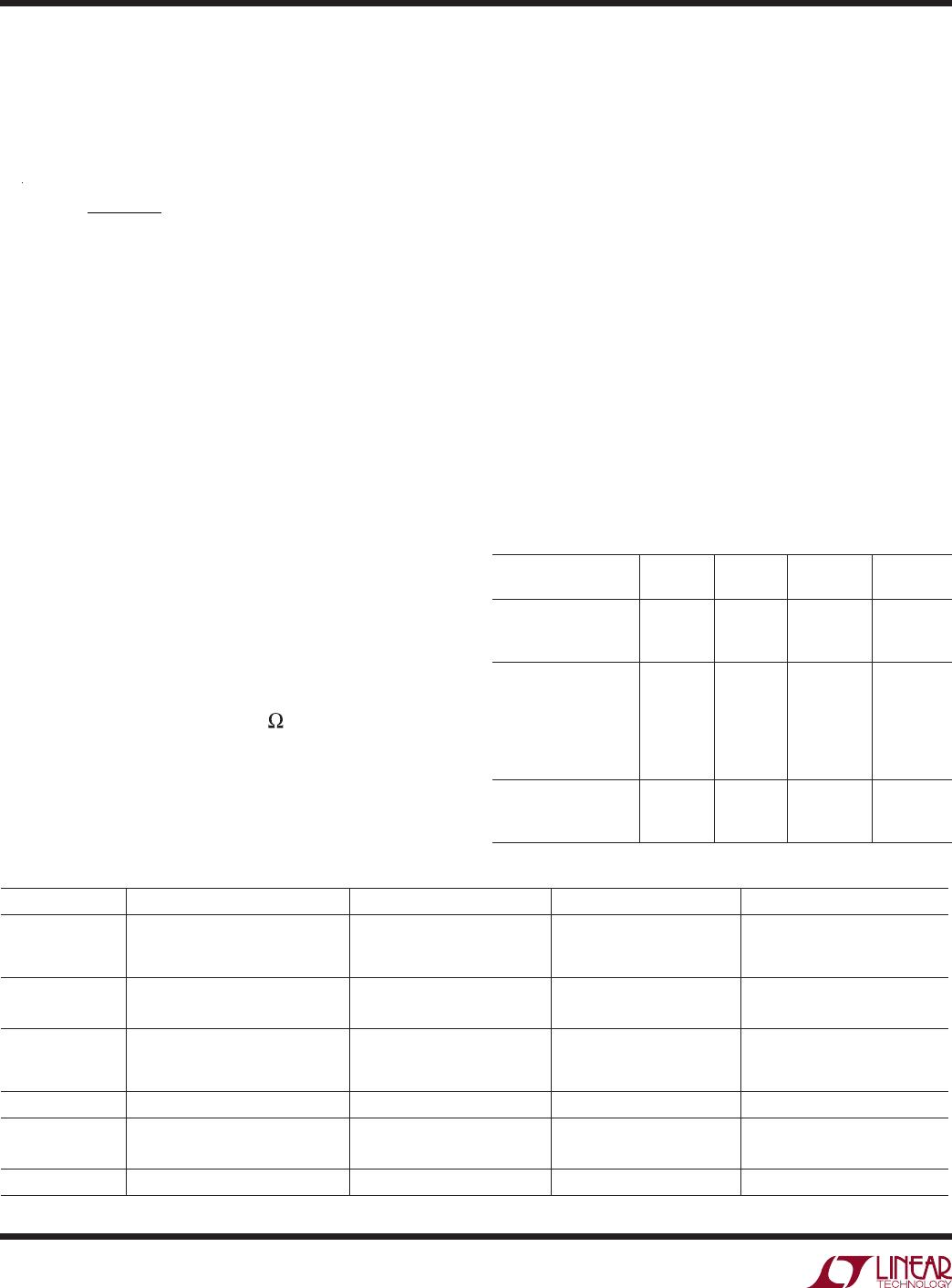

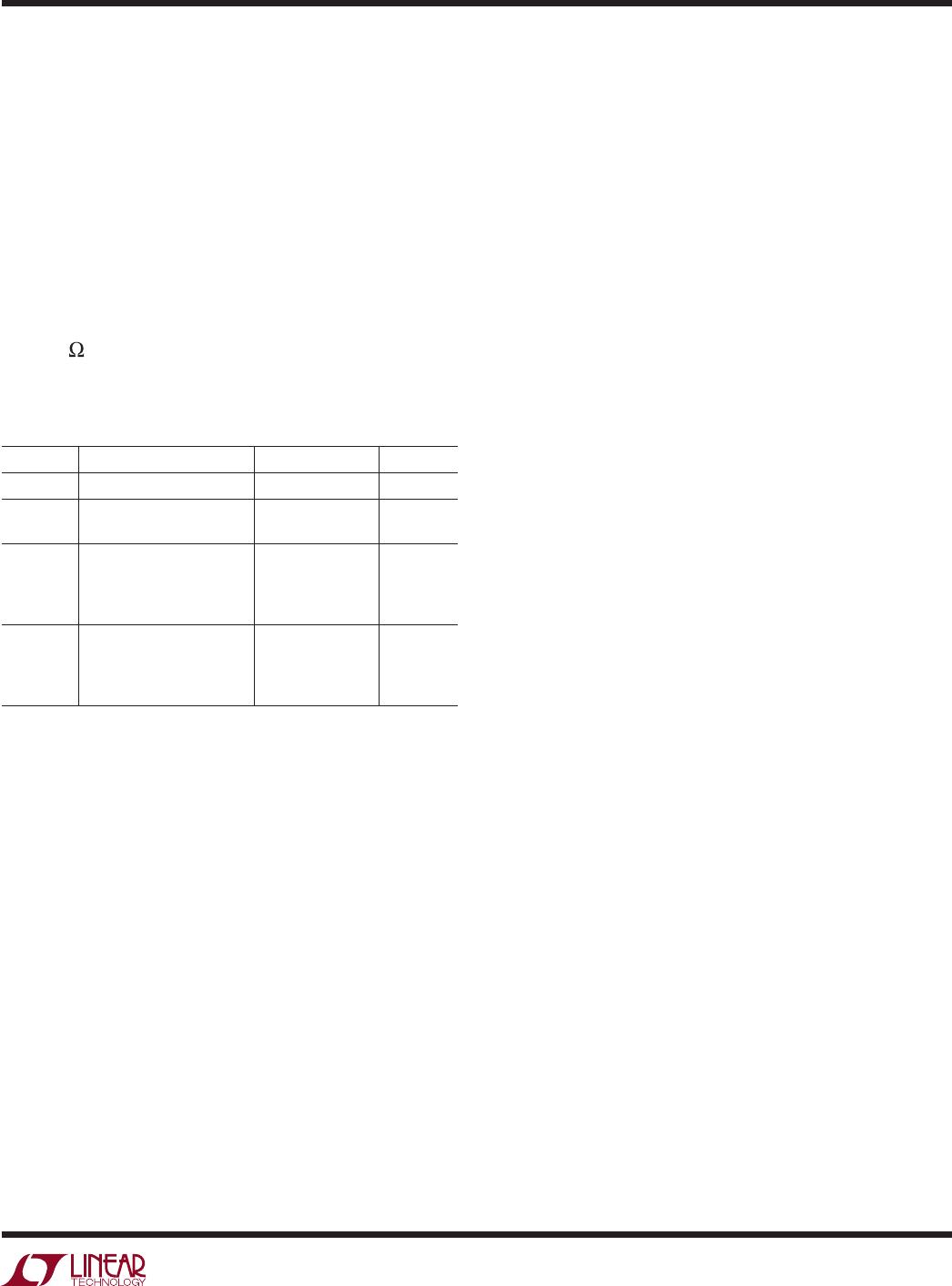

Table 1. Inductor Vendors

VENDOR URL PART SERIES TYPE

Murata www.murata.com LQH55D Open

TDK www.componenttdk.com SLF7045

SLF10145

Shielded

Shielded

Toko www.toko.com D62CB

D63CB

D75C

D75F

Shielded

Shielded

Shielded

Open

Sumida www.sumida.com CR54

CDRH74

CDRH6D38

CR75

Open

Shielded

Shielded

Open

Of course, such a simple design guide will not always re-

sult in the optimum inductor for your application. A larger

value inductor provides a slightly higher maximum load

current and will reduce the output voltage ripple. If your

load is lower than 2A, then you can decrease the value of

the inductor and operate with higher ripple current. This

allows you to use a physically smaller inductor, or one

with a lower DCR resulting in higher efficiency. There are

several graphs in the Typical Performance Characteristics

section of this data sheet that show the maximum load

current as a function of input voltage and inductor value

for several popular output voltages. Low inductance may

result in discontinuous mode operation, which is okay

but further reduces maximum load current. For details of

maximum output current and discontinuous mode opera-

tion, see Linear Technology Application Note 44. Finally,

for duty cycles greater than 50% (V

OUT

/V

IN

> 0.5), there

is a minimum inductance required to avoid subharmonic

oscillations. See AN19.

Input Capacitor

Bypass the input of the LT3480 circuit with a ceramic capaci-

tor of X7R or X5R type. Y5V types have poor performance

over temperature and applied voltage, and should not be

used. A 4.7µF to 10µF ceramic capacitor is adequate to

bypass the LT3480 and will easily handle the ripple current.

Note that larger input capacitance is required when a lower

switching frequency is used. If the input power source has

high impedance, or there is significant inductance due to

long wires or cables, additional bulk capacitance may be

necessary. This can be provided with a lower performance

electrolytic capacitor.

Step-down regulators draw current from the input sup-

ply in pulses with very fast rise and fall times. The input

capacitor is required to reduce the resulting voltage

ripple at the LT3480 and to force this very high frequency

switching current into a tight local loop, minimizing EMI.

A 4.7µF capacitor is capable of this task, but only if it is

placed close to the LT3480 and the catch diode (see the

PCB Layout section). A second precaution regarding the

ceramic input capacitor concerns the maximum input

voltage rating of the LT3480. A ceramic input capacitor

combined with trace or cable inductance forms a high

quality (under damped) tank circuit. If the LT3480 circuit

is plugged into a live supply, the input voltage can ring to

twice its nominal value, possibly exceeding the LT3480’s

voltage rating. This situation is easily avoided (see the Hot

Plugging Safely section).

For space sensitive applications, a 2.2µF ceramic capaci-

tor can be used for local bypassing of the LT3480 input.

However, the lower input capacitance will result in in-

creased input current ripple and input voltage ripple, and

may couple noise into other circuitry. Also, the increased

voltage ripple will raise the minimum operating voltage

of the LT3480 to ~3.7V.

Output Capacitor and Output Ripple

The output capacitor has two essential functions. Along

with the inductor, it filters the square wave generated by the

LT3480 to produce the DC output. In this role it determines

the output ripple, and low impedance at the switching

frequency is important. The second function is to store