LTC2927

7

2927fb

0.8V

–

+

–

+

5

RAMPBUF

5

RAMP

2927 F06

5

V

CC

5

5

FB

5

ON

5

TRACK

1.2V

10μA

10μA

V

CC

1x

R

ONB

R

ONA

MASTER

SLAVE

DC/DC

C

RAMP

R

TB

R

FB

R

FA

R

TA

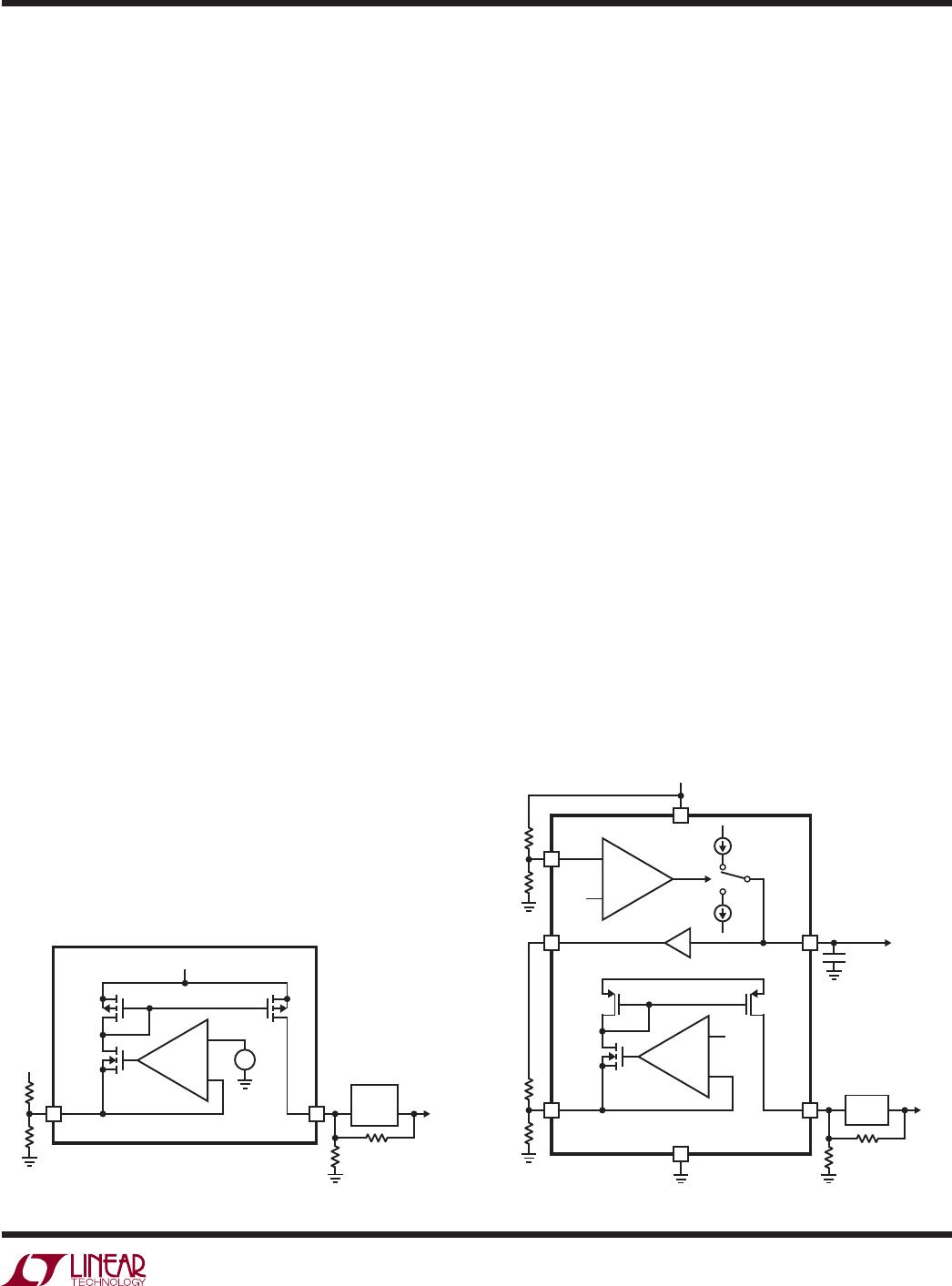

Figure 6. Simplifi ed Functional DiagramFigure 5. Simplifi ed Tracking Cell

0.8V

–

+

2927 F05

5

FB

5

TRACK

V

CC

MASTER

SLAVE

FB OUT

DC/DC

R

TB

R

FB

R

FA

R

TA

+

–

pin is mirrored at the FB pin to establish a voltage at the

output of the slave supply. The slave output voltage varies

with the master signal, enabling the slave supply to be

controlled as a function of the master signal with terms

set by R

TA

and R

TB

. By selecting appropriate values of

R

TA

and R

TB

, it is possible to generate any of the profi les

in Figures 1 to 4.

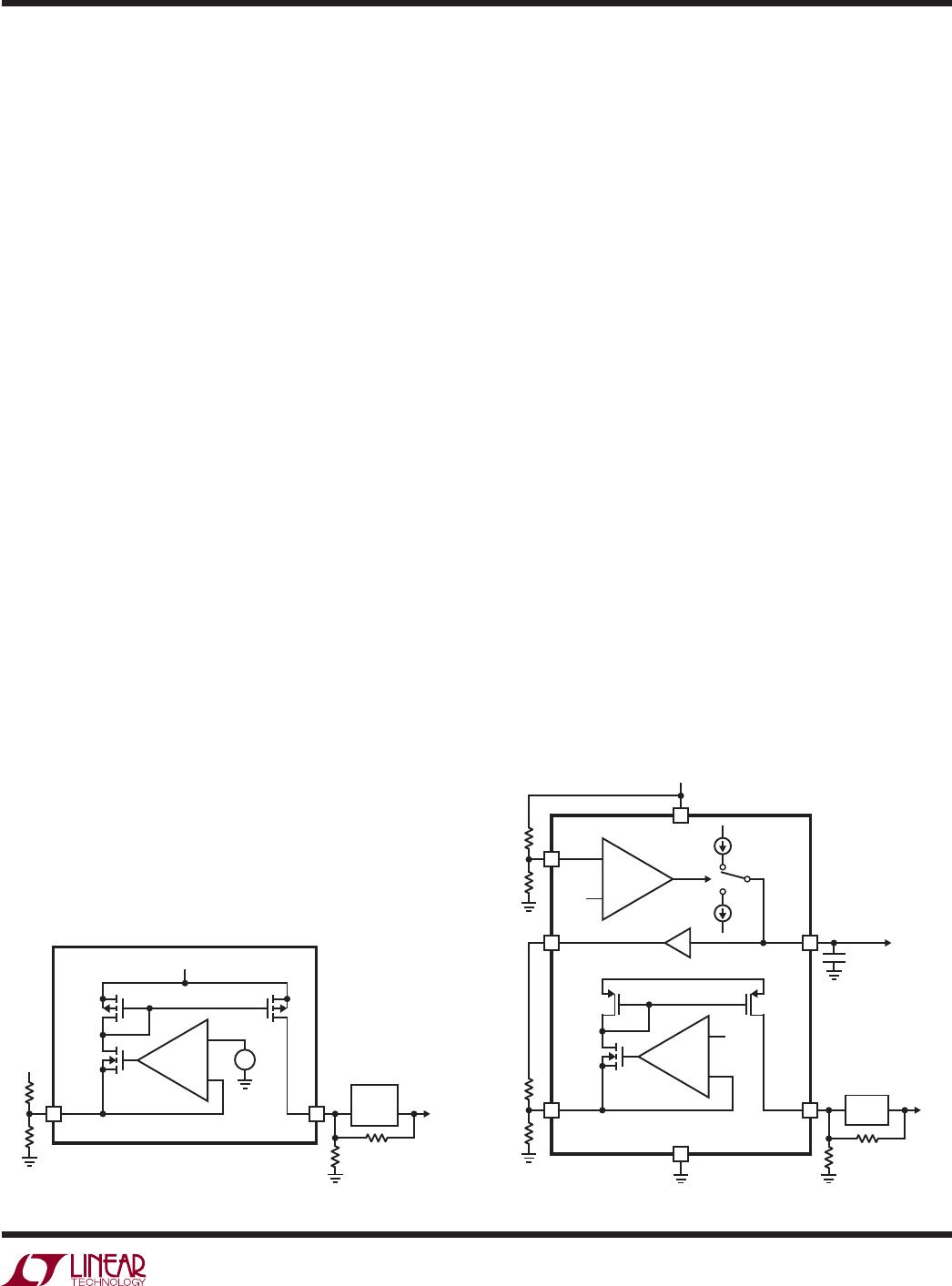

Controlling the Ramp-Up and Ramp-Down Behavior

The operation of the LTC2927 is most easily understood

by referring to the simplifi ed functional diagram in Figure

6. When the ON pin is low, the master signal at the RAMP

pin is pulled to ground. Since the current through R

TB

is

at its maximum when the master signal is low, the current

from FB is also at its maximum. This current drives the

slave output to its minimum voltage.

When the ON pin rises above 1.23V, the master signal

rises and the slave supply tracks the master signal. The

ramp rate is set by an external capacitor driven by a 10μA

current source at the RAMP pin. Alternatively, the RAMP

pin can be connected to a separate supply to be used as

the master signal.

In a properly designed system, when the master signal

has reached its maximum voltage the current from the

TRACK pin is zero. In this case, there is no current from

the FB pin and the LTC2927 has no effect on the output

voltage accuracy, transient response or stability of the

slave supply.

When the ON pin falls below V

ON(TH)

– ΔV

ON(HYST)

, typi-

cally 1.225V, the RAMP pin pulls down with 10μA and the

master signal and slave supplies will fall at the same rate

as they rose previously.

The ON pin can be controlled by a digital I/O pin or it

can be used to monitor an input supply. By connecting a

resistive divider from an input supply to the ON pin, the

supplies will ramp up only after the monitored supply has

reached a preset voltage.

If a resistive divider is used to set the ON pin voltage, choose

values that will keep this voltage above the maximum ON

pin threshold voltage of 1.25V at the lowest operating

supply level.

The Ramp Buffer

The RAMPBUF pin provides a buffered version of the

RAMP pin voltage that drives the resistive divider on the

TRACK pin. The buffered master signal provides up to

2mA to drive the resistors.

Shutdown Output

In some applications it might be necessary to control

the shutdown or RUN/SS pins of the slave supplies. The

LTC2927 may not be able to supply the rated 1mA of current

from the FB pin when V

CC

is below 2.9V. If the slave power

supply is capable of operating at low input voltages, use

the open-drain SDO output to drive the SHDN or RUN/SS

pin of the slave supply (see Figure 7). This will hold the

slave supply output low until the ON pin is above 1.23V

and V

CC

is above the 2.5V undervoltage lockout condition.

APPLICATIO S I FOR ATIO

WUU

U