AD7858/AD7858L

REV. B

–21–

Automatic Calibration on Power-On

The CAL pin has a 0.15 µA pull-up current source connected

to it internally to allow for an automatic full self-calibration on

power-on. A full self-calibration will be initiated on power-on if

a capacitor is connected from the CAL pin to DGND. The

internal current source connected to the CAL pin charges up

the external capacitor and the time required to charge the exter-

nal capacitor will depend on the size of the capacitor itself. This

time should be large enough to ensure that the internal refer-

ence is settled before the calibration is performed. A 33 nF

capacitor is sufficient to ensure that the internal reference has

settled (see Power-Up Times) before a calibration is initiated

taking into account trigger level and current source variations

on the CAL pin. However, if an external reference is being

used, this reference must have stabilized before the automatic

calibration is initiated (a larger capacitor on the CAL pin

should be used if the external reference has not settled when the

autocalibration is initiated). Once the capacitor on the CAL pin

has charged, the calibration will be performed which will take

32 ms (4 MHz CLKIN). Therefore the autocalibration should

be complete before operating the part. After calibration, the

part is accurate to the 12-bit level and the specifications quoted

on the data sheet apply. There will be no need to perform

another calibration unless the operating conditions change or

unless a system calibration is required.

Self-Calibration Description

There are four different calibration options within the self-

calibration mode. First, there is a full self-calibration where the

DAC, internal gain, and internal offset errors are calibrated out.

Then, there is the (Gain + Offset) self-calibration which cali-

brates out the internal gain error and then the internal offset

errors. The internal DAC is not calibrated here. Finally, there

are the self-offset and self-gain calibrations which calibrate out

the internal offset errors and the internal gain errors respectively.

The internal capacitor DAC is calibrated by trimming each of

the capacitors in the DAC. It is the ratio of these capacitors to

each other that is critical, and so the calibration algorithm en-

sures that this ratio is at a specific value by the end of the cali-

bration routine. For the offset and gain there are two separate

capacitors, one of which is trimmed when an offset or gain

calibration is performed. Again, it is the ratio of these capacitors

to the capacitors in the DAC that is critical and the calibration

algorithm ensures that this ratio is at a specified value for both

the offset and gain calibrations.

The zero-scale error is adjusted for an offset calibration, and

the positive full-scale error is adjusted for a gain calibration.

Self-Calibration Timing

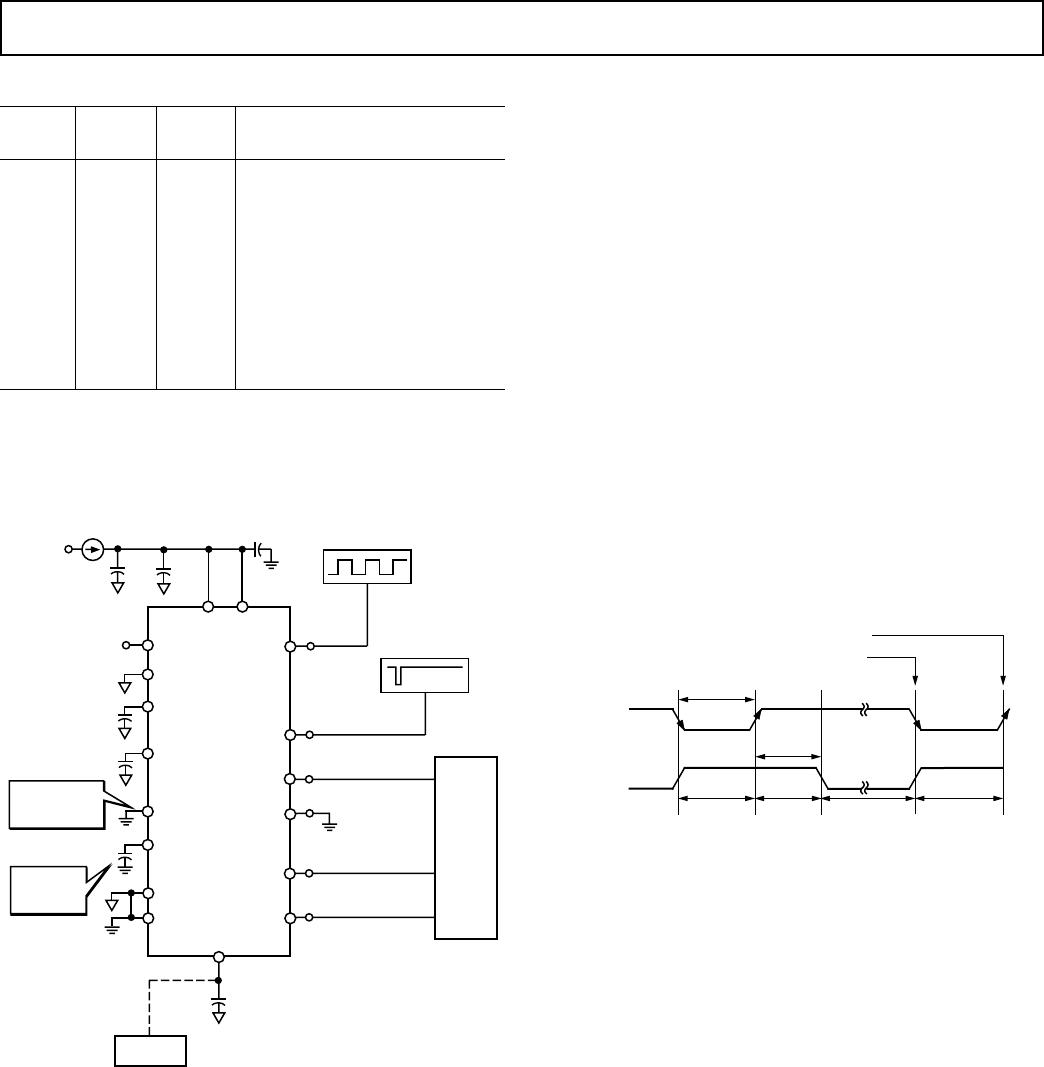

The diagram of Figure 25 shows the timing for a full self-

calibration. Here the BUSY line stays high for the full length of

the self-calibration. A self-calibration is initiated by bringing the

CAL pin low (which initiates an internal reset) and then high

again or by writing to the control register and setting the STCAL

bit to 1 (note that if the part is in a power-down mode the CAL pulse-

width must take account of the power-up time ). The BUSY line is

triggered high from the rising edge of CAL (or the end of the

write to the control register if calibration is initiated in soft-

ware), and BUSY will go low when the full self-calibration is

complete after a time t

CAL

as shown in Figure 25.

For the self- (gain + offset), self-offset, and self-gain calibrations

the BUSY line will be triggered high by the rising edge of the

CAL signal (or the end of the write to the control register if

calibration is initiated in software) and will stay high for the

full duration of the self-calibration. The length of time that

the BUSY is high will depend on the type of self-calibration

that is initiated. Typical figures are given in Table VIII. The

timing diagrams for the other self-calibration options will be

similar to that outlined in Figure 25.

t

1

= 100ns MIN,

t

15

= 2.5

t

CLKIN

MAX,

t

CAL

= 125013

t

CLKIN

t

1

t

15

t

CAL

BUSY (O/P)

CAL (I/P)

Figure 25. Timing Diagram for Full Self-Calibration

System Calibration Description

System calibration allows the user to take out system errors

external to the AD7858/AD7858L as well as calibrate the errors

of the AD7858/AD7858L itself. The maximum calibration

range for the system offset errors is ±5% of V

REF

and for the

system gain errors is ±2.5% of V

REF

. This means that the maxi-

mum allowable system offset voltage applied between the

AIN(+) and AIN(–) pins for the calibration to adjust out this

error is ±0.05 × V

REF

(i.e., the AIN(+) can be 0.05

×

V

REF

above

AIN(–) or 0.05

×

V

REF

below AIN(–)). For the System gain error

the maximum allowable system full-scale voltage that can be

applied between AIN(+) and AIN(–) for the calibration to

adjust out this error is V

REF

± 0.025

×

V

REF

( i.e., the AIN(+)

above AIN(–)). If the system offset or system gain errors are

outside the ranges mentioned the system calibration algorithm

will reduce the errors as much as the trim range allows.

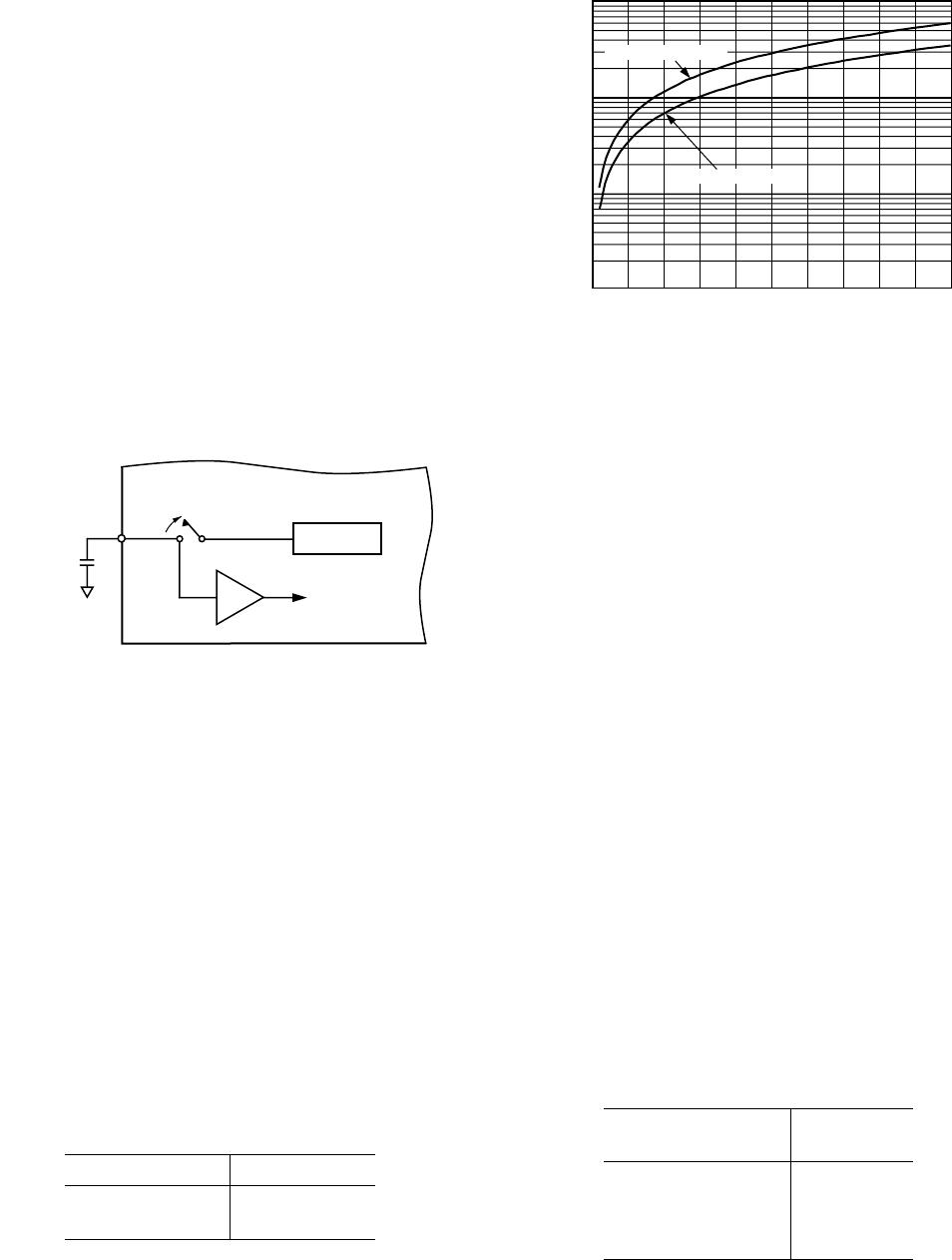

Figures 26 through 28 illustrate why a specific type of system

calibration might be used. Figure 26 shows a system offset

calibration (assuming a positive offset) where the analog input

range has been shifted upwards by the system offset after the

system offset calibration is completed. A negative offset may

also be accounted for by a system offset calibration.

MAX SYSTEM OFFSET

IS ⴞ5% OF V

REF

V

REF

–1LSB

SYS OFFSET

AGND

ANALOG

INPUT

RANGE

MAX SYSTEM FULL SCALE

IS ⴞ2.5% FROM V

REF

SYSTEM OFFSET

CALIBRATION

MAX SYSTEM OFFSET

IS ⴞ5% OF V

REF

SYS OFFSET

AGND

V

REF

+ SYS OFFSET

V

REF

– 1LSB

ANALOG

INPUT

RANGE

Figure 26. System Offset Calibration