LTC2450-1

14

24501fc

APPLICATIONS INFORMATION

Digital Signal Levels

The LTC2450-1’s digital interface is easy to use. Its digital

inputs (SCK and CS) accept standard CMOS logic levels

and the internal hysteresis receivers can tolerate edge

rates as slow as 100μs. However, some considerations

are required to take advantage of the exceptional accuracy

and low supply current of this converter.

The digital output signal SDO is less of a concern because

it is not active during the conversion cycle.

While a digital input signal is in the range 0.5V to V

CC

–0.5V, the CMOS input receiver may draw additional

current from the power supply. Due to the nature of CMOS

logic, a slow transition within this voltage range may cause

an increase in the power supply current drawn by the

converter, particularly in the low power operation mode

within the SLEEP state. Thus, for low power consumption

it is highly desirable to provide relatively fast edges for the

two digital input pins SCK and CS, and to keep the digital

input logic levels at V

CC

or GND.

At the same time, during the CONVERT state, undershoot

and/or overshoot of fast digital signals connected to the

LTC2450-1 pins may affect the conversion result. Under-

shoot and overshoot can occur because of an impedance

mismatch at the converter pin combined with very fast

transition times. This problem becomes particularly diffi cult

when shared control lines are used and multiple refl ec-

tions may occur. The solution is to carefully terminate all

transmission lines close to their characteristic impedance.

Parallel termination is seldom an acceptable option in low

power systems so a series resistor between 27Ω and 56Ω

placed near the driver may eliminate this problem. The

actual resistor value depends upon the trace impedance

and connection topology. An alternate solution is to reduce

the edge rate of the control signals, keeping in mind the

concerns regarding slow edges mentioned above.

Particular attention should be given to confi gurations in

which a continuous clock signal is applied to SCK pin dur-

ing the CONVERT state. While LTC2450-1 will ignore this

signal from a logic point of view the signal edges may create

unexpected errors depending upon the relation between

its frequency and the internal oscillator frequency. In such

a situation it is benefi cial to use edge rates of about 10ns

and to limit potential undershoot to less than 0.3V below

GND and overshoot to less than 0.3V above V

CC

.

Noisy external circuitry can potentially impact the output

under 2-wire operation. In particular, it is possible to get

the LTC2450-1 into an unknown state if an SCK pulse is

missed or noise triggers an extra SCK pulse. In this situ-

ation, it is impossible to distinguish SDO = 1 (indicating

conversion in progress) from valid “1” data bits. As such,

CPOL = 1 is recommended for the 2-wire mode. The user

should look for SDO = 0 before reading data, and look

for SDO = 1 after reading data. If SDO does not return a

“0” within the maximum conversion time (or return a “1”

after a full data read), generate 16 SCK pulses to force a

new conversion.

Driving V

CC

and GND

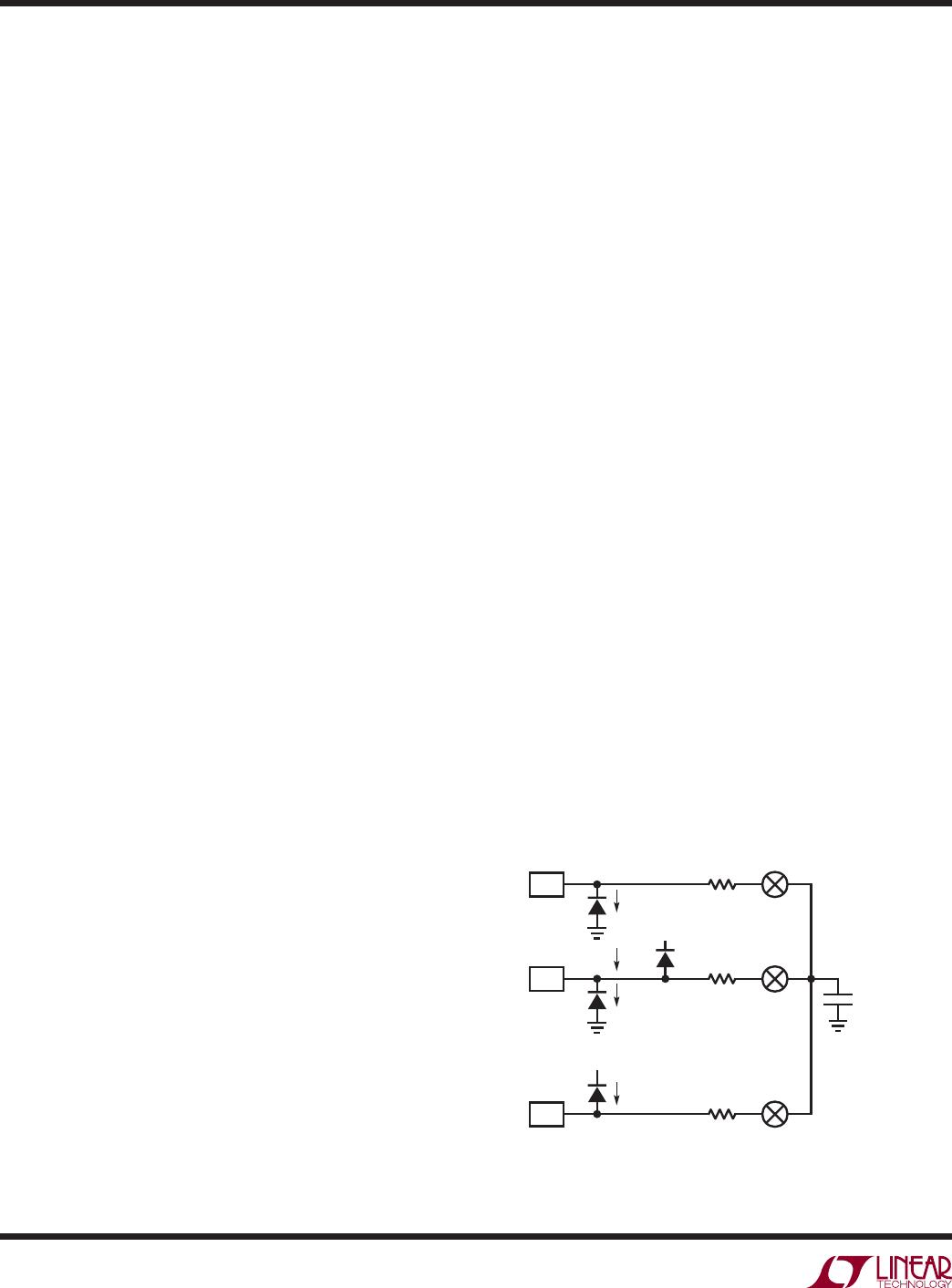

The V

CC

and GND pins of the LTC2450-1 converter are

directly connected to the positive and negative reference

voltages, respectively. A simplifi ed equivalent circuit is

shown in Figure 14.

The power supply current passing through the parasitic

layout resistance associated with these common pins will

modify the ADC reference voltage and thus negatively affect

the converter accuracy. It is thus important to keep the

V

CC

and GND lines quiet, and to connect these supplies

through very low impedance traces.

In relation to the V

CC

and GND pins, the LTC2450-1 com-

bines internal high frequency decoupling with damping

Figure 14. LTC2450-1 Analog Pins Equivalent Circuit

V

CC

I

LEAK

R

SW

(TYP)

15k

C

EQ

(TYP)

0.35pF

INTERNAL SWITCHING FREQUENCY = 4 MHz

R

SW

(TYP)

15k

R

SW

(TYP)

15k

V

IN

I

LEAK

I

LEAK

GND

I

LEAK

V

CC

V

CC

V

CC

24501 F14