LT3082

11

3082f

APPLICATIONS INFORMATION

two equal inductors in parallel, but placing them in close

proximity gives the wires mutual inductance adding to

the self-inductance. The second and most effective way

to reduce overall inductance is to place both forward and

return current conductors (the input and GND wires) in

very close proximity. Two 30-AWG wires separated by

only 0.02", used as forward- and return-current conduc-

tors, reduce the overall self-inductance to approximately

one-fi fth that of a single isolated wire.

If wiring modifi cations are not permissible for the applica-

tions, including series resistance between the power supply

and the input of the LT3082 also stabilizes the application.

As little as 0.1 to 0.5, often less, is effective in damping

the LC resonance. If the added impedance between the

power supply and the input is unacceptable, adding ESR to

the input capacitor also provides the necessary damping of

the LC resonance. However, the required ESR is generally

higher than the series impedance required.

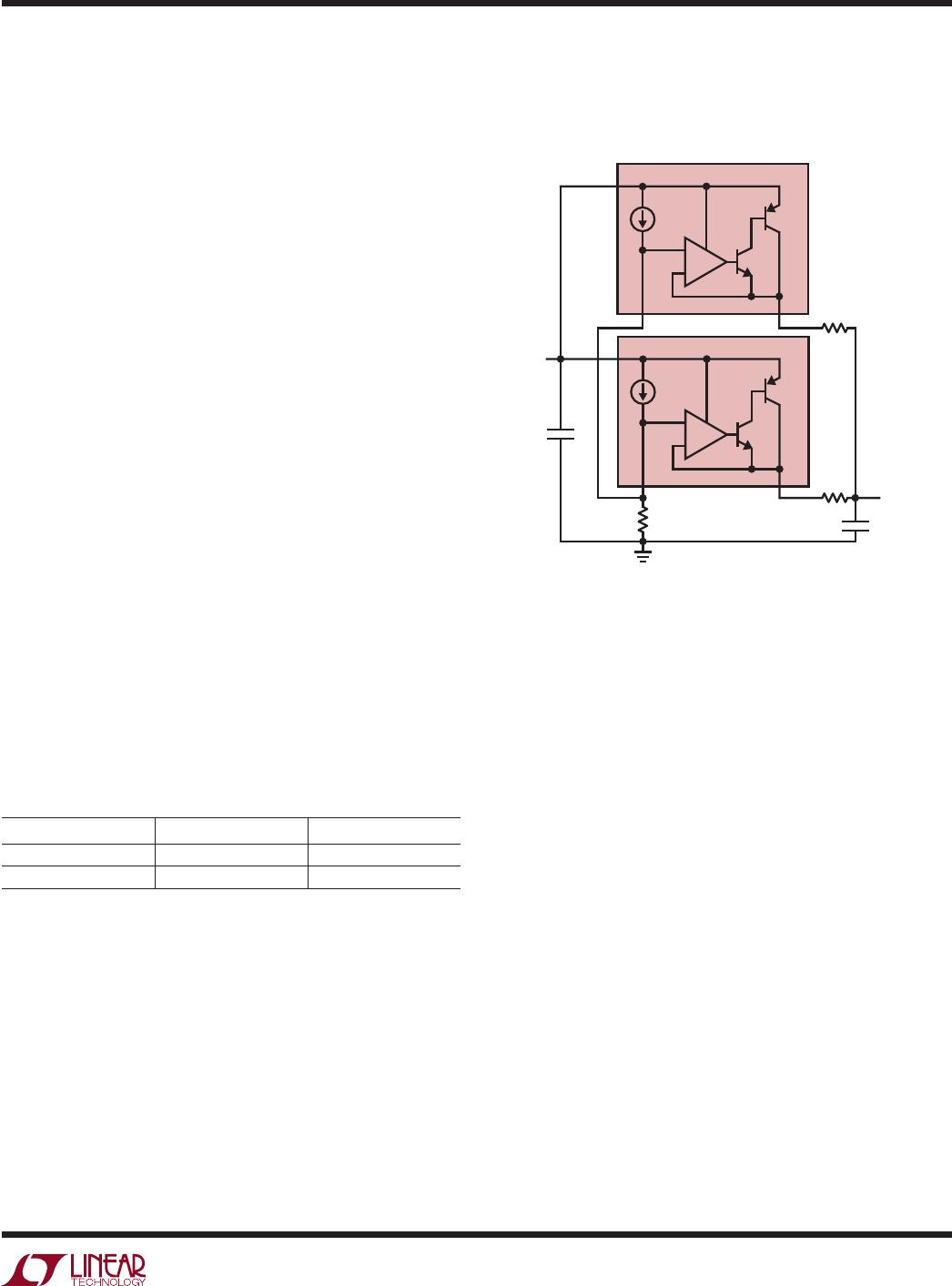

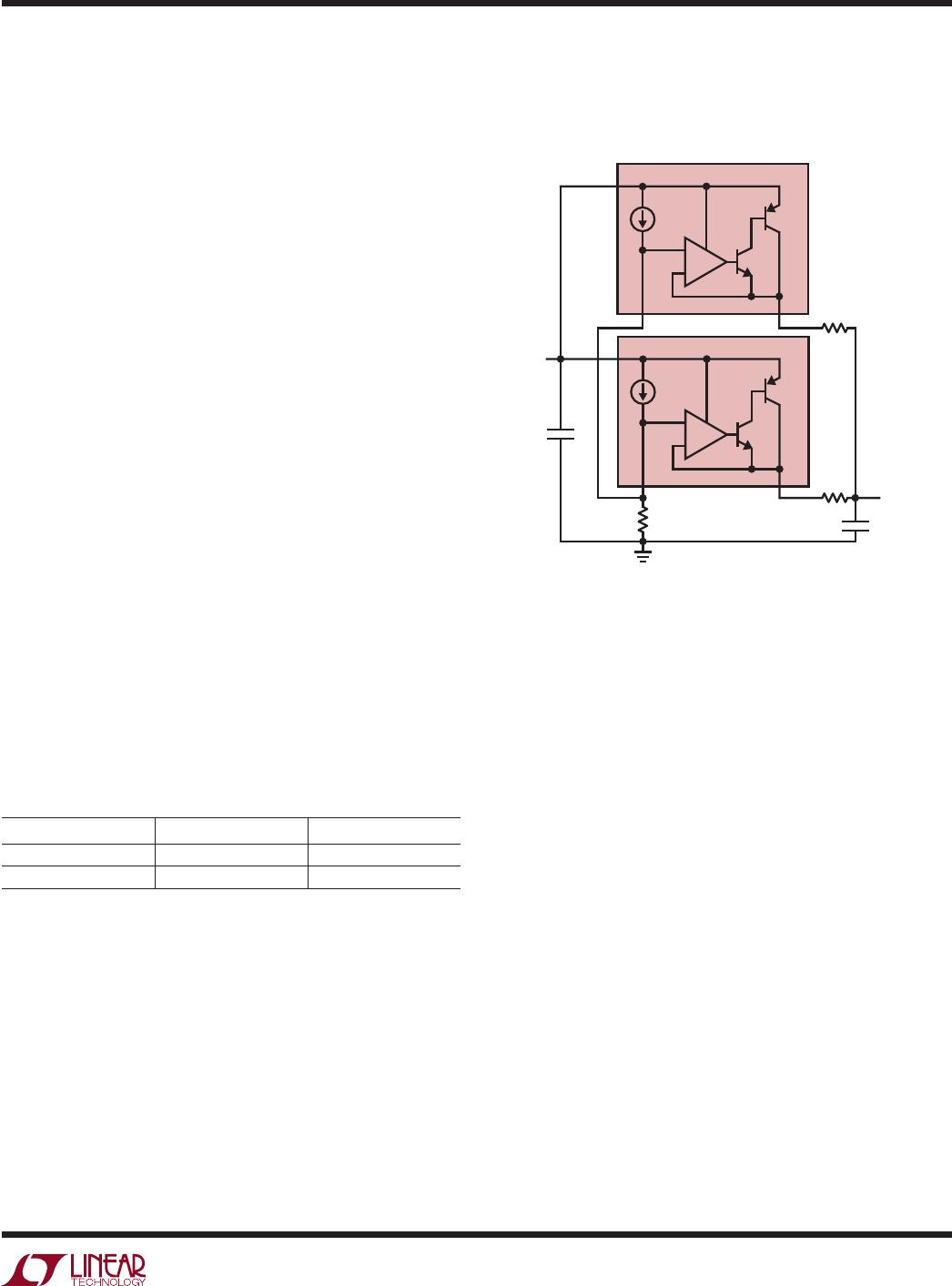

Paralleling Devices

Higher output current is obtained by paralleling multiple

LT3082s together. Tie the individual SET pins together and

tie the individual IN pins together. Connect the outputs in

common using small pieces of PC trace as ballast resistors

to promote equal current sharing. PC trace resistance in

m/inch is shown in Table 2. Ballasting requires only a

tiny area on the PCB.

Table 2. PC Board Trace Resistance

WEIGHT (oz) 10mil WIDTH 20mil WIDTH

1 54.3 27.1

2 27.1 13.6

Trace resistance is measured in m/in

The worst-case room temperature offset, only ±2mV

between the SET pin and the OUT pin, allows the use of

very small ballast resistors.

As shown in Figure 5, each LT3082 has a small 50m

ballast resistor, which at full output current gives better

than 80% equalized sharing of the current. The external

resistance of 50m (25m for the two devices in paral-

lel) adds only about 10mV of output regulation drop at an

output of 0.4A. Even with an output voltage as low as 1V,

this adds only 1% to the regulation. Of course, paralleling

more than two LT3082s yields even higher output current.

Spreading the devices on the PC board also spreads the

heat. Series input resistors can further spread the heat if

the input-to-output difference is high.

Figure 5. Parallel Devices

SET

+

–

LT3082

10µA

50m

50m

IN

V

IN

4.8V TO

40V

V

OUT

, 3.3V

0.4A

OUT

10µF

1µF

165k

3082 F05

SET

+

–

LT3082

10µA

IN

OUT

Quieting the Noise

The LT3082 offers numerous noise performance advan-

tages. Every linear regulator has its sources of noise. In

general, a linear regulator’s critical noise source is the

reference. In addition, consider the error amplifi er’s noise

contribution along with the resistor divider’s noise gain.

Many traditional low noise regulators bond out the voltage

reference to an external pin (usually through a large value

resistor) to allow for bypassing and noise reduction. The

LT3082 does not use a traditional voltage reference like

other linear regulators. Instead, it uses a 10A reference

current. The 10A current source generates noise current

levels of 2.7pA/√Hz (0.7nA

RMS

over the 10Hz to 100kHz

bandwidth). The equivalent voltage noise equals the RMS

noise current multiplied by the resistor value.

The SET pin resistor generates spot noise equal to √4kTR

(k = Boltzmann’s constant, 1.38 • 10

–23

J/°K, and T is abso-

lute temperature) which is RMS summed with the voltage

noise If the application requires lower noise performance,

bypass the voltage/current setting resistor with a capacitor

to GND. Note that this noise-reduction capacitor increases

start-up time as a factor of the RC time constant.