DS3882

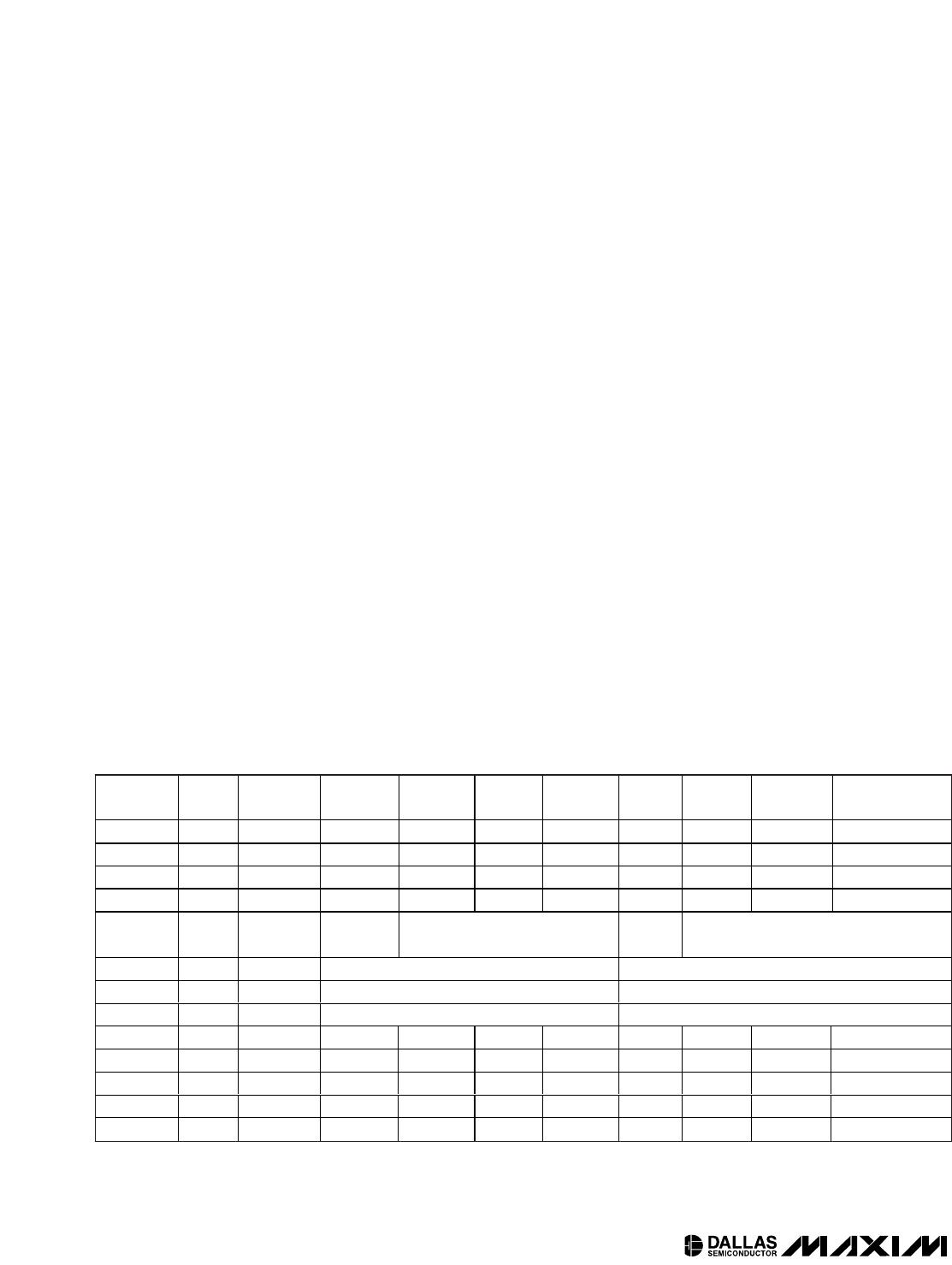

Figure 8 shows a flowchart of how the DS3882 controls

and monitors each lamp. The steps are as follows:

1) Supply Check—The lamps do not turn on unless the

DS3882 supply voltage is above 4.3V and the volt-

age at the supply voltage monitors, SVML and SVMH,

are respectively above 2.0V and below 2.0V.

2) Strike Lamp—When both the DS3882 and the DC

inverter supplies are at acceptable levels, the

DS3882 attempts to strike each enabled lamp. The

DS3882 slowly ramps up the MOSFET gate duty

cycle until the lamp strikes. The controller detects

that the lamp has struck by detecting current flow in

the lamp, detected by the LCMn pin. If during the

strike ramp, the maximum allowable voltage is

reached on the OVDn pin, the controller stops

increasing the MOSFET gate duty cycle to keep from

overstressing the system. The DS3882 goes into a

fault handling state (step 4) if the lamp has not struck

after the timeout period as defined by the LST0 and

LST1 control bits in the SSP1 register. If an overvolt-

age event is detected during the strike attempt, the

DS3882 disables the MOSFET gate drivers and go

into the fault handling state.

3) Run Lamp—Once the lamp is struck, the DS3882

adjusts the MOSFET gate duty cycle to optimize the

lamp current. The gate duty cycle is always con-

strained to keep the system from exceeding the

maximum allowable lamp voltage. The lamp current

sampling rate is user-selectable using the LSR0 and

LSR1 bits in CR2. If lamp current ever drops below the

lamp out reference point for the period as defined by

the LST0 and LST1 control bits in the SSP1 register,

then the lamp is considered extinguished. In this case,

the MOSFET gate drivers are disabled and the device

moves to the fault handling stage.

4) Fault Handling—During fault handling, the DS3882

performs an optional (user-selectable) automatic

retry to attempt to clear all faults except a lamp over-

current. The automatic retry makes 14 additional

attempts to rectify the fault before declaring the

channel in a fault state and permanently disabling

the channel. Between each of the 14 attempts, the

controller waits 1024 lamp cycles. In the case of a

lamp overcurrent, the DS3882 instantaneously

declares the channel to be in a fault state and per-

manently disables the channel. The DS3882 can be

configured to disable all channels if one or more

channels enter a fault state or it can be configured to

disable only the channel where the fault occurred.

Once a fault state is entered, the channel remains in

that state until one of the following occurs:

• V

CC

drops below the UVLO threshold.

• The SVML or SVMH thresholds are crossed.

• The PDN pin goes high.

• The PDNE software bit is written to a logic 1.

• The channel is disabled by the CH1D or CH2D

control bit.

Dual-Channel Automotive CCFL Controller

16 ____________________________________________________________________