© 2009 Microchip Technology Inc. Preliminary DS22131C-page 9

25LCXXX

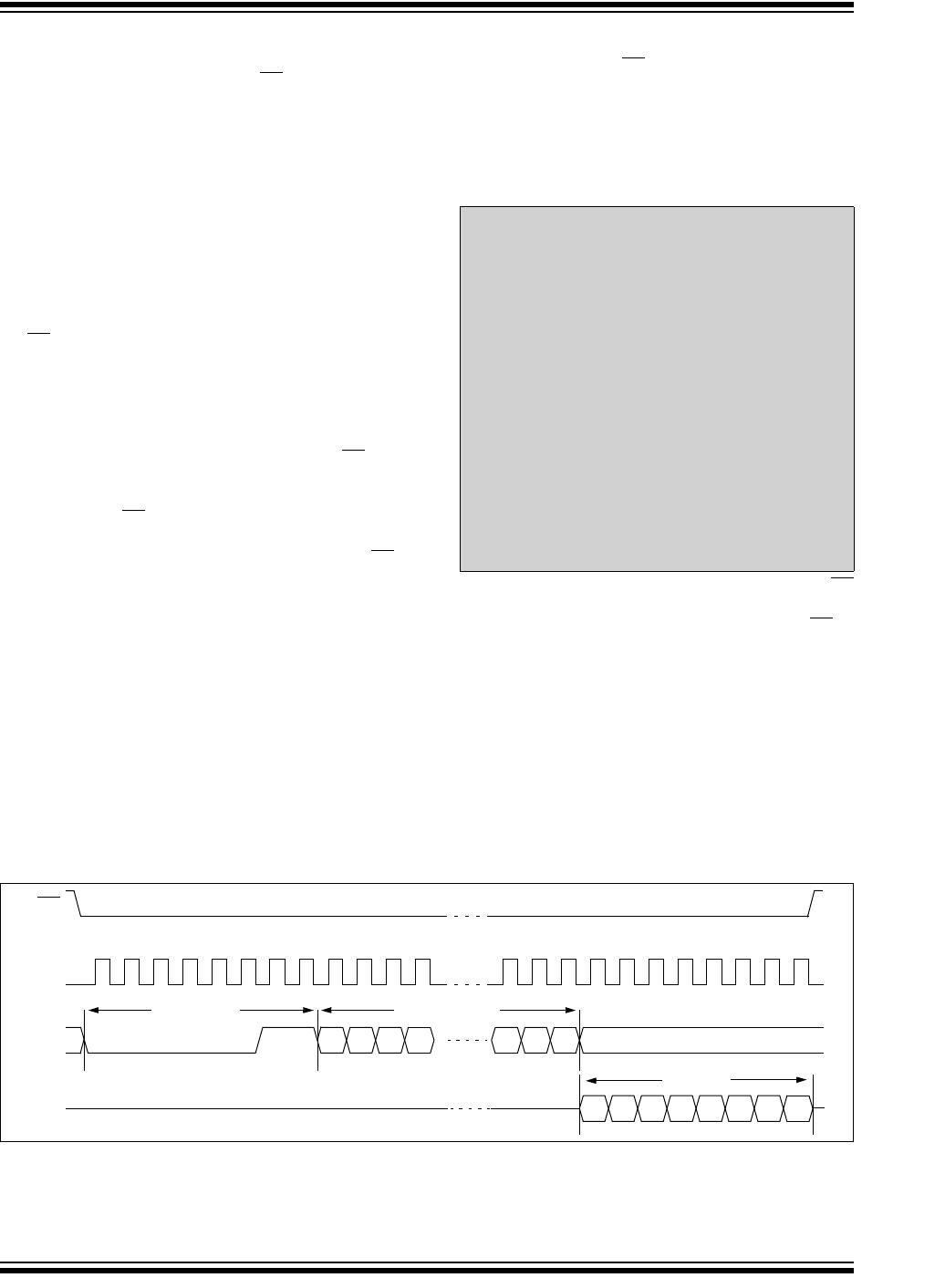

3.2 Read Sequence

The device is selected by pulling CS low. The 8-bit

READ instruction is transmitted to the 25LCXXX fol-

lowed by the 16-bit address. After the correct READ

instruction and address are sent, the data stored in the

memory at the selected address is shifted out on the

SO pin. The data stored in the memory at the next

address can be read sequentially by continuing to pro-

vide clock pulses. The internal Address Pointer is auto-

matically incremented to the next higher address after

each byte of data is shifted out. When the highest

address is reached, the address counter rolls over to

address 0000h allowing the read cycle to be continued

indefinitely. The read operation is terminated by raising

the CS

pin (Figure 3-1).

3.3 Write Sequence

Prior to any attempt to write data to the 25LCXXX, the

write enable latch must be set by issuing the WREN

instruction (Figure 3-4). This is done by setting CS low

and then clocking out the proper instruction into the

25LCXXX. After all eight bits of the instruction are

transmitted, the CS

must be brought high to set the

write enable latch. If the write operation is initiated

immediately after the WREN instruction without CS

being brought high, the data will not be written to the

array because the write enable latch will not have been

properly set.

Once the write enable latch is set, the user may

proceed by setting the CS

low, issuing a WRITE instruc-

tion, followed by the 16-bit address, and then the data

to be written. Depending upon the density, a page of

data that ranges from 16 bytes to 64 bytes can be sent

to the device before a write cycle is necessary. The only

restriction is that all of the bytes must reside in the

same page.

For the data to be actually written to the array, the CS

must be brought high after the Least Significant bit (D0)

of the n

th

data byte has been clocked in. If CS is

brought high at any other time, the write operation will

not be completed. Refer to Figure 3-2 and Figure 3-3

for more detailed illustrations on the byte write

sequence and the page write sequence, respectively.

While the write is in progress, the STATUS register may

be read to check the status of the WPEN, WIP, WEL,

BP1 and BP0 bits (Figure 3-6). A read attempt of a

memory array location will not be possible during a

write cycle. When the write cycle is completed, the

write enable latch is reset.

FIGURE 3-1: READ SEQUENCE

Note: Page write operations are limited to writing

bytes within a single physical page,

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buffer size (or

‘page size’) and, end at addresses that are

integer multiples of page size – 1. If a

Page Write command attempts to write

across a physical page boundary, the

result is that the data wraps around to the

beginning of the current page (overwriting

data previously stored there), instead of

being written to the next page as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.

SO

SI

SCK

CS

0 234567891011 21222324252627282930311

0100000115 14 13 12 210

76543210

Instruction 16-bit Address

Data Out

High-Impedance