LTC3550-1

13

35501f

OPERATIO

U

600mA Step-Down Regulator

The LTC3550-1 regulator uses a constant frequency, cur-

rent mode step-down architecture. Both the top (P-channel

MOSFET) and bottom (N-channel MOSFET) switches are

internal. During normal operation, the internal top power

MOSFET is turned on each cycle when the oscillator sets

the RS latch, and is turned off when the current com-

parator, I

COMP

, resets the RS latch. The peak inductor

current at which I

COMP

resets the RS latch, is controlled

by the output of error amplifi er EA. When the load current

increases, it causes a slight decrease in the output voltage

(V

OUT

), relative to the internal reference, which in turn

causes the EA amplifi er’s output voltage to increase until

the average inductor current matches the new load cur-

rent. While the top MOSFET is off, the bottom MOSFET is

turned on until either the inductor current starts to reverse,

as indicated by the current reversal comparator I

RCMP

, or

the beginning of the next clock cycle.

Burst Mode

®

Operation

The LTC3550-1 buck regulator is capable of Burst Mode

operation in which the internal power MOSFETs operate

intermittently based on load current demand.

In Burst Mode operation, the peak current of the inductor is

set to approximately 200mA regardless of the output load.

Each burst event can last from a few cycles at light loads

to almost continuously cycling with short sleep intervals

at moderate loads. In between these burst events, the

power MOSFETs and any unneeded circuitry are turned

off, reducing the quiescent current to 20µA. In this sleep

state, the load current is being supplied solely from the

output capacitor. As the output voltage droops, the EA

amplifi er’s output rises above the sleep threshold signaling

the BURST comparator to trip and turn the top MOSFET

on. This process repeats at a rate that is dependent on

the load demand.

Dropout Operation

As the input supply voltage decreases to a value approach-

ing the output voltage, the duty cycle increases toward the

maximum on-time. Further reduction of the supply voltage

forces the main switch to remain on for more than one cycle

until it reaches 100% duty cycle. The output voltage will

then be determined by the input voltage minus the voltage

drop across the P-channel MOSFET and the inductor.

An important detail to remember is that at low input supply

voltages, the R

DS(ON)

of the P-channel switch increases

(see Typical Performance Characteristics). Therefore,

the user should calculate the power dissipation when the

LTC3550-1 is used at 100% duty cycle with low input

voltage (See Thermal Considerations in the Applications

Information section).

Battery Charger Power Source Selection

The LTC3550-1 can charge a battery from either the wall

adapter input or the USB port input. The charger automati-

cally senses the presence of voltage at each input. If both

power sources are present, the charger defaults to the wall

adapter source provided suffi cient power is present at the

DCIN input. “Suffi cient power” is defi ned as:

• Supply voltage is greater than the UVLO threshold.

• Supply voltage is greater than the battery voltage by

50mV (180mV rising, 50mV falling).

The open drain power status outputs (

⎯

P

⎯

W

⎯

R and USBPWR)

indicate which power source has been selected. Table 1

describes the behavior of these status outputs.

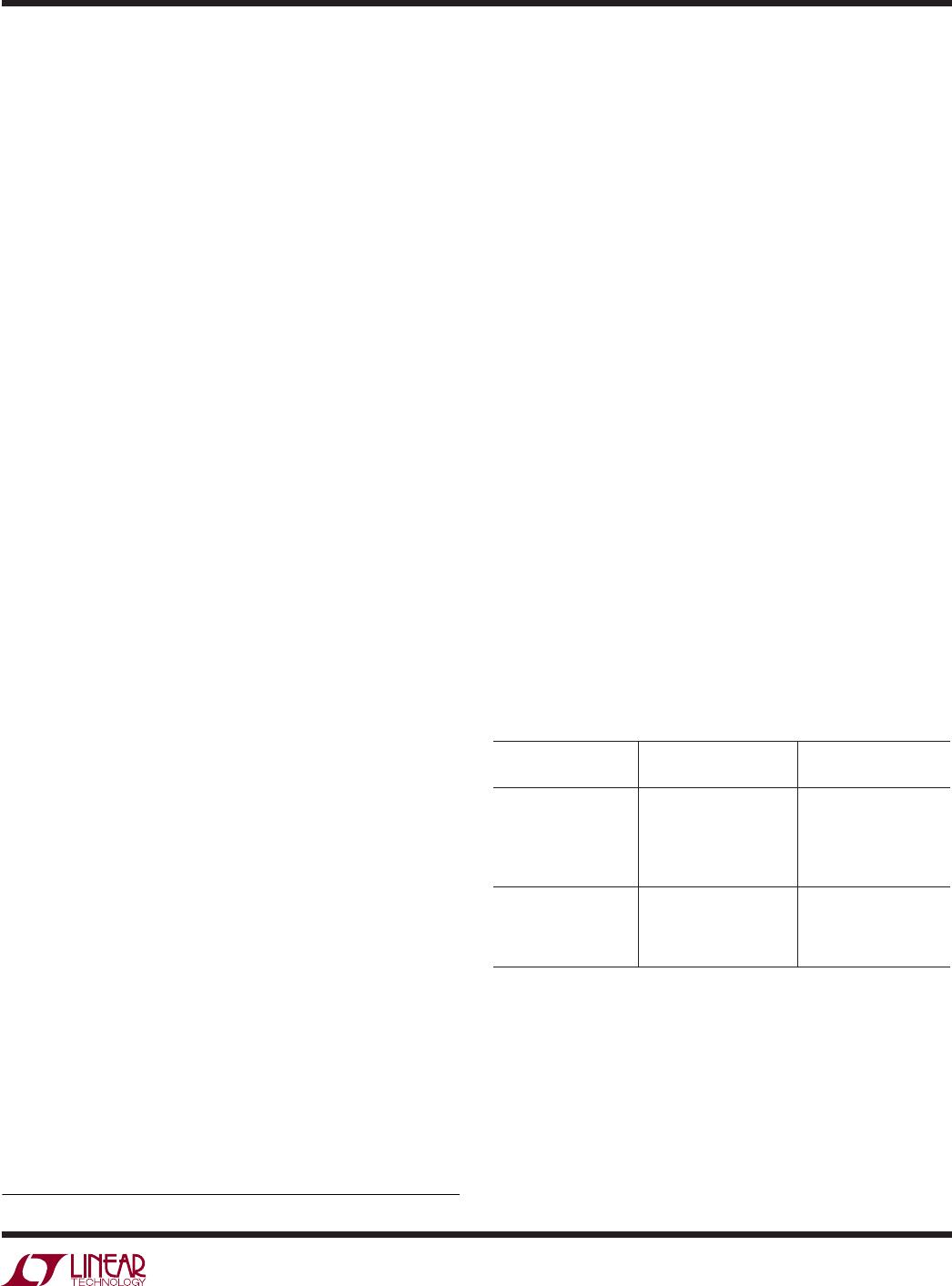

Table 1. Power Source Selection

V

USBIN

> 3.95V and

V

USBIN

> BAT + 50mV

V

USBIN

< 3.95V or

V

USBIN

< BAT + 50mV

V

DCIN

> 4.15V and

V

DCIN

> BAT + 50mV

Device Powered from

Wall Adapter Source;

USBIN Current < 25µA

⎯

P

⎯

W

⎯

R: LOW

USBPWR: LOW

Device Powered from

Wall Adapter Source

⎯

P

⎯

W

⎯

R: LOW

USBPWR: LOW

V

DCIN

< 4.15V or

V

DCIN

< BAT + 50mV

Device Powered from

USB Source;

⎯

P

⎯

W

⎯

R: LOW

USBPWR: Hi-Z

No Charging

⎯

P

⎯

W

⎯

R: Hi-Z

USBPWR: LOW

Status Indicators

The charge status output (

⎯

C

⎯

H

⎯

R

⎯

G) has two states: pull-

down and high impedance. The pull-down state indicates

that the LTC3550-1 is in a charge cycle. Once the charge

cycle has terminated or the LTC3550-1 is disabled, the

pin state becomes high impedance. The pull-down state

is strong enough to drive an LED and is capable of sink-

ing up to 10mA.

Burst Mode is a registered trademark of Linear Technology Corporation.