NB3H63143G

www.onsemi.com

18

APPLICATION GUIDELINES

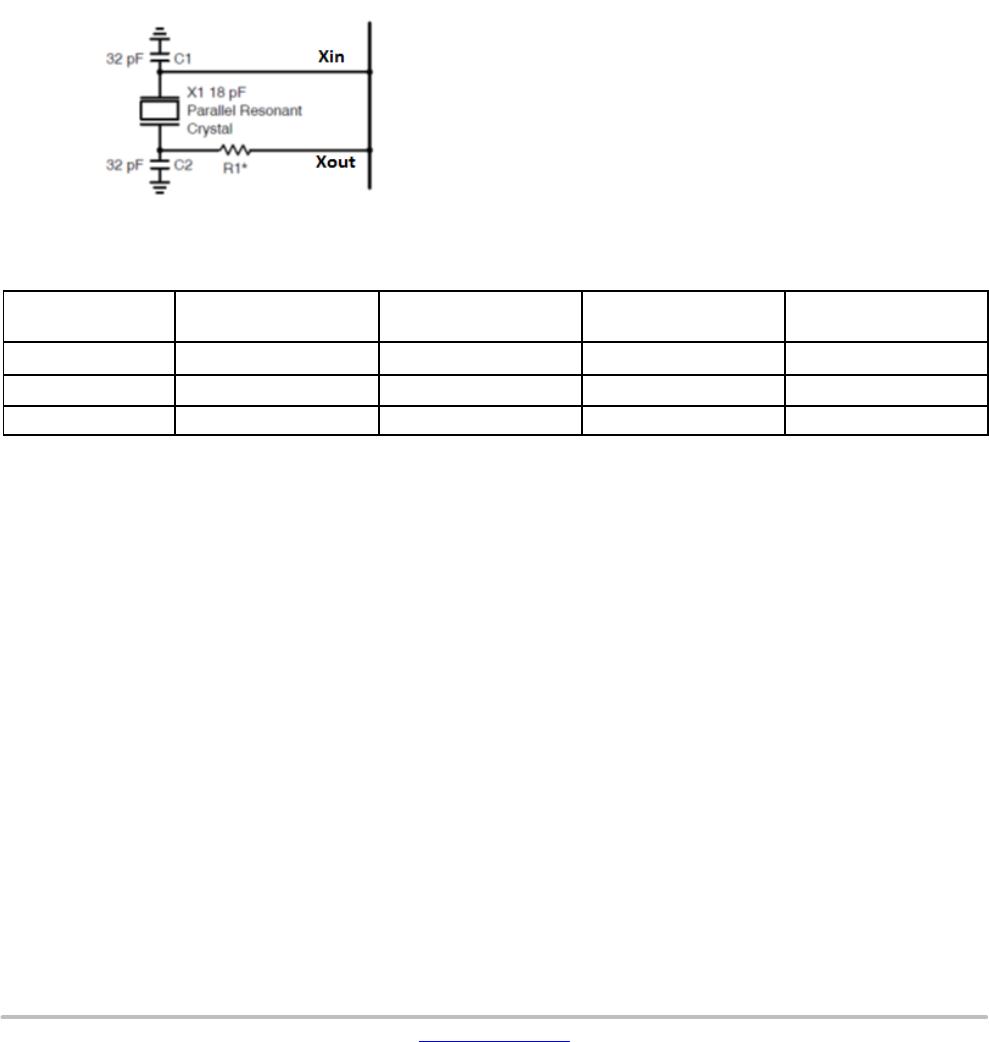

Crystal Input Interface

Figure 16 shows the NB3H63143G device crystal

oscillator interface using a typical parallel resonant

fundamental mode crystal. A parallel crystal with loading

capacitance CL = 18 pF would use C1 = 32 pF and C2 =

32 pF as nominal values, assuming 4 pF of stray capacitance

per line.

C

L

+

(

C1 ) Cstray

)

ń2; C1 + C2

The frequency accuracy and duty cycle skew can be

fine−tuned by adjusting the C1 and C2 values. For example,

increasing the C1 and C2 values will reduce the operational

frequency. Note R1 is optional and may be 0 W.

Figure 16. Crystal Interface Loading

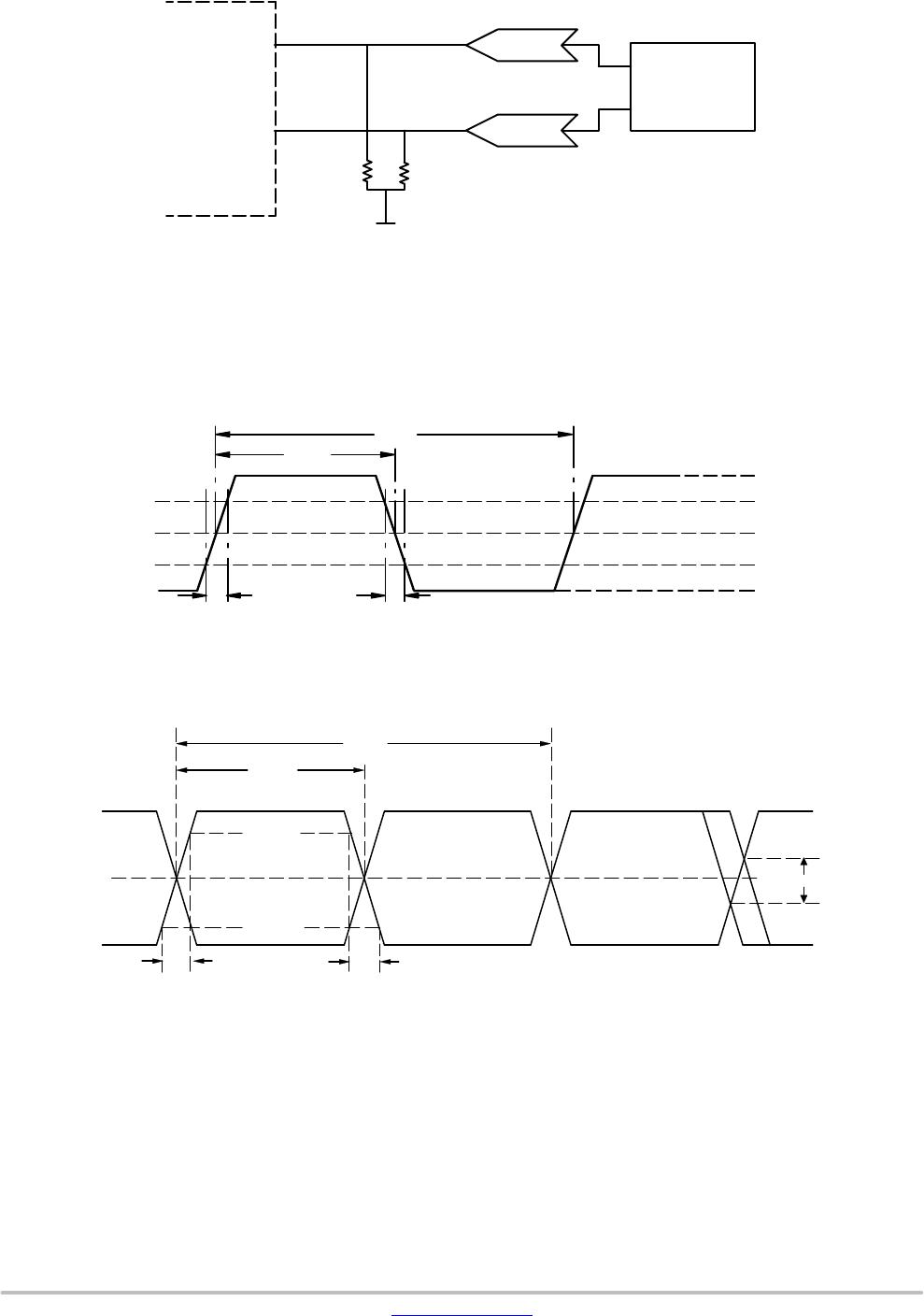

Output Interface and Terminations

The NB3H63143G consists of a unique Multi Standard

Output Driver to support LVCMOS/LVTTL, LVPECL,

LVDS, HCSL and CML standards. Termination techniques

required for each of these standards are different to ensure

proper functionality. From the device it is possible to switch

off one output driver and turn on another output driver using

the SEL[1:0] pins as part of the Configuration Settings. The

required termination changes must be considered and taken

care of by the system designer.

LVCMOS/LVTTL Interface

LVCMOS/LVTTL output swings rail−to−rail up to

VDDO supply (minimum 1.8 V) and can drive up to 15 pF

load at higher drive stengths. The output buffer’s drive is

programmable up to four steps, though the drive current will

depend on the step setting as well as the VDDO supply

voltage. (See Figure 17 and Table 8). Drive strength must be

configured high for driving higher loads. The slew rate of the

clock signal increases with higher output current drive for

the same load. The software lets the user choose the load

drive current value per LVCMOS/LVTTL output based on

the VDDO supply selected.

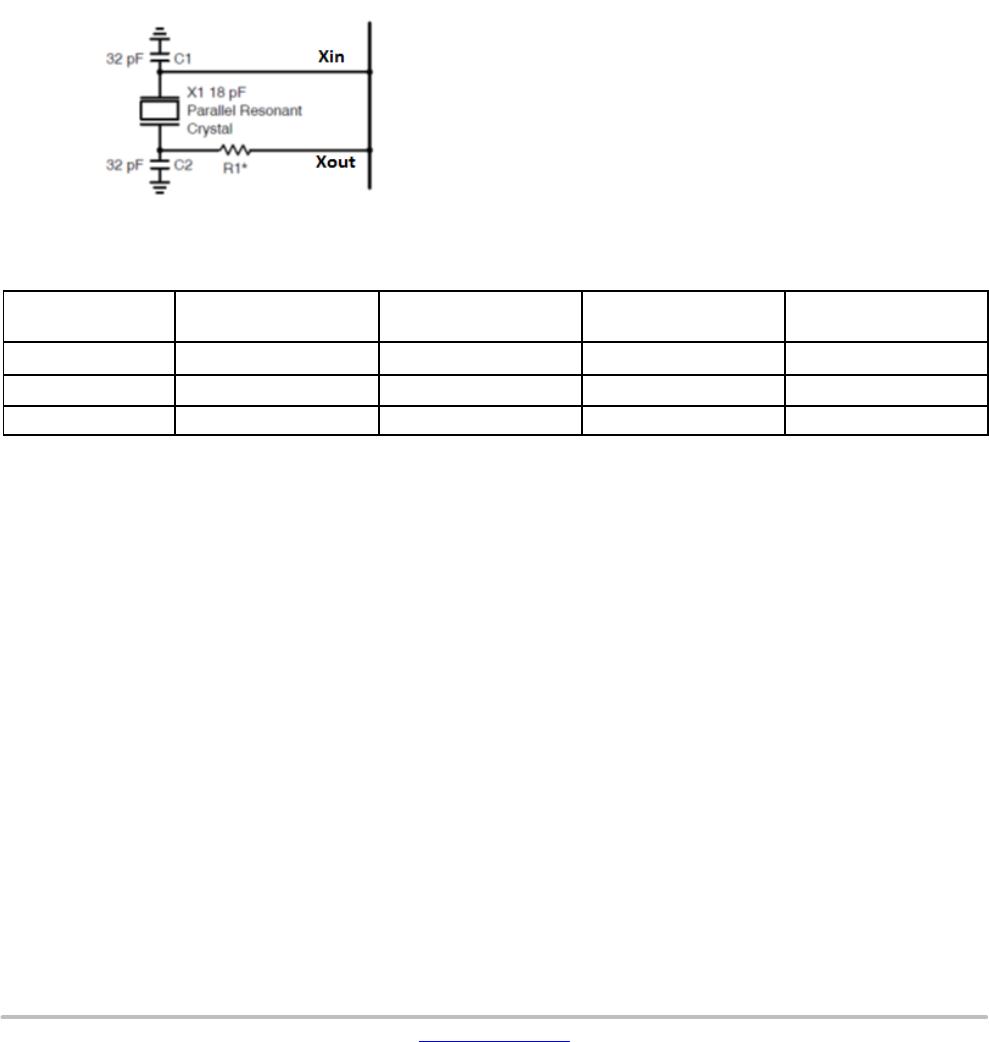

Table 8. LVCMOS/LVTTL DRIVE LEVEL SETTINGS

VDDO Supply

Load Current Setting 3

Max Load Current

Load Current Setting 2 Load Current Setting 1

Load Current Setting 0

Min Load Current

3.3 V 16 mA 12 mA 8 mA 4 mA

2.5 V 12 mA 8 mA 4 mA 2 mA

1.8 V 8 mA 4 mA 2 mA 1 mA

The IDDO current consists of the static current

component (varies with drive) and dynamic current

component. For any VDDO, the IDDO dynamic current

range per LVCMOS output can be approximated by the

following:

IDDO + f

out

*C

load

* VDDO

C

load

includes the load capacitor connected to the output,

the pin capacitor posed by the output pin (typically 5 pF) and

the cap load posed by the receiver input pin. C

load

= (CL +

C

pin

+ C

in

)

An optional series resistor Rs can be connected at the

output for impedance matching, to limit the overshoots and

ringings.