24AA65/24LC65/24C65

DS21073K-page 6 © 2008 Microchip Technology Inc.

3.6 Device Addressing

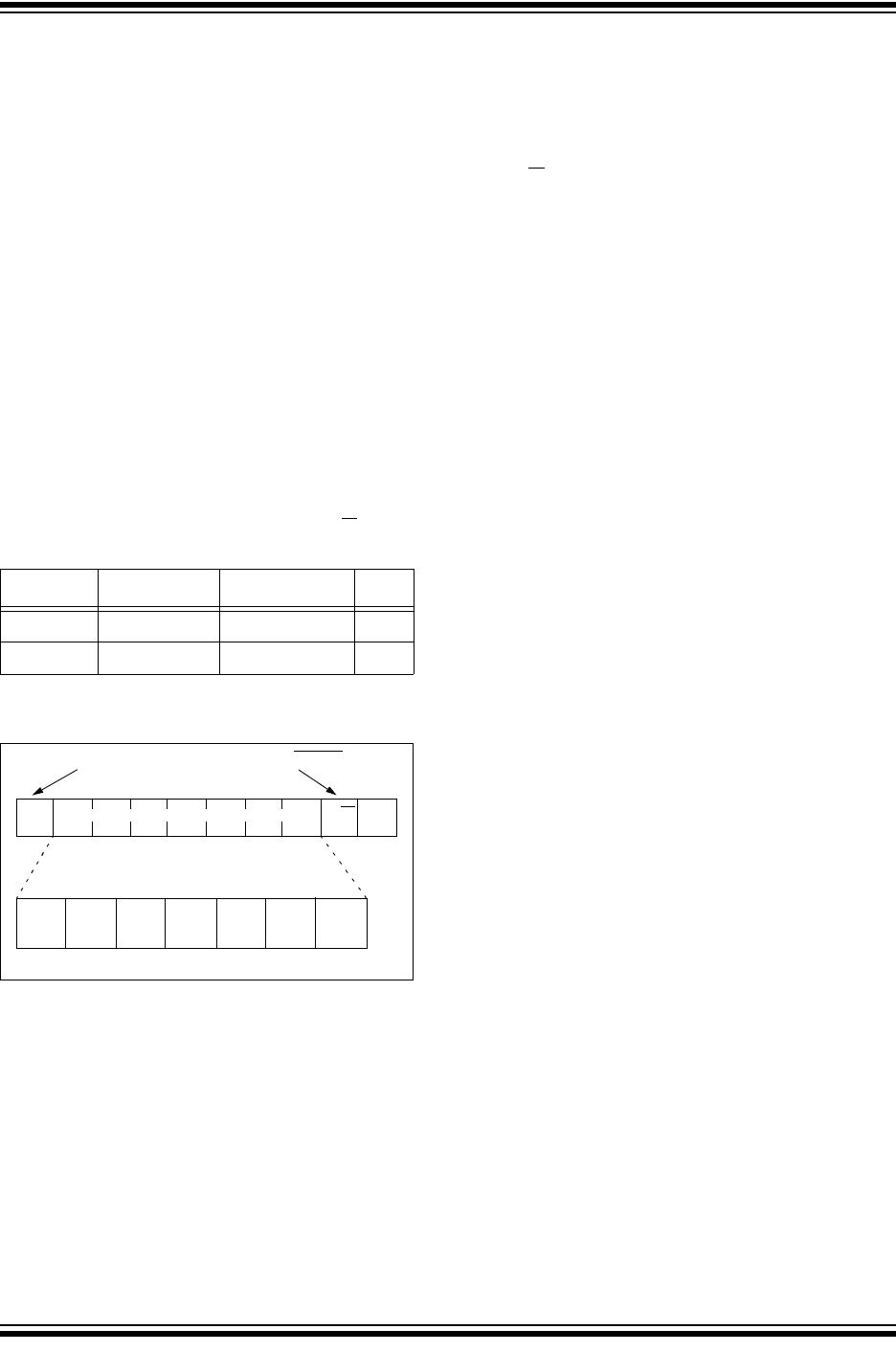

A control byte is the first byte received following the

Start condition from the master device. The control byte

consists of a four-bit control code, for the 24XX65 this

is set as ‘1010’ binary for read and write operations.

The next three bits of the control byte are the device

select bits (A2, A1, A0). They are used by the master

device to select which of the eight devices are to be

accessed. These bits are in effect the three Most

Significant bits of the word address. The last bit of the

control byte defines the operation to be performed.

When set to a one a read operation is selected, when

set to a zero a write operation is selected. The next two

bytes received define the address of the first data byte

(Figure 4-1). Because only A12..A0 are used, the

upper three address bits must be zeros. The Most

Significant bit of the Most Significant Byte is transferred

first. Following the Start condition, the 24XX65

monitors the SDA bus checking the device type

identifier being transmitted. Upon receiving a ‘1010’

code and appropriate device select bits, the slave

device (24XX65) outputs an Acknowledge signal on the

SDA line. Depending upon the state of the R/W

bit, the

24XX65 will select a read or write operation.

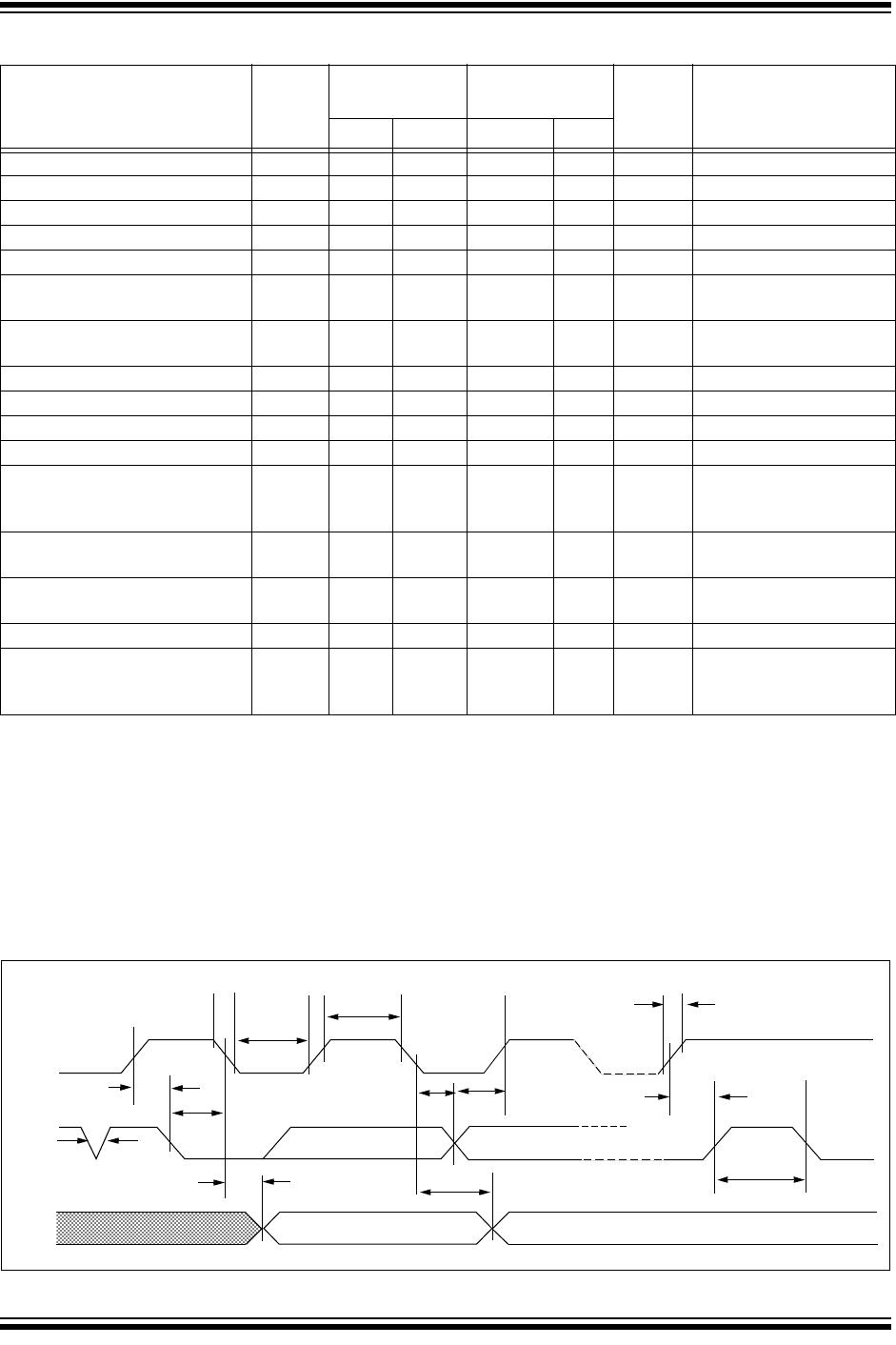

FIGURE 3-2: CONTROL BYTE

ALLOCATION

4.0 WRITE OPERATION

4.1 Byte Write

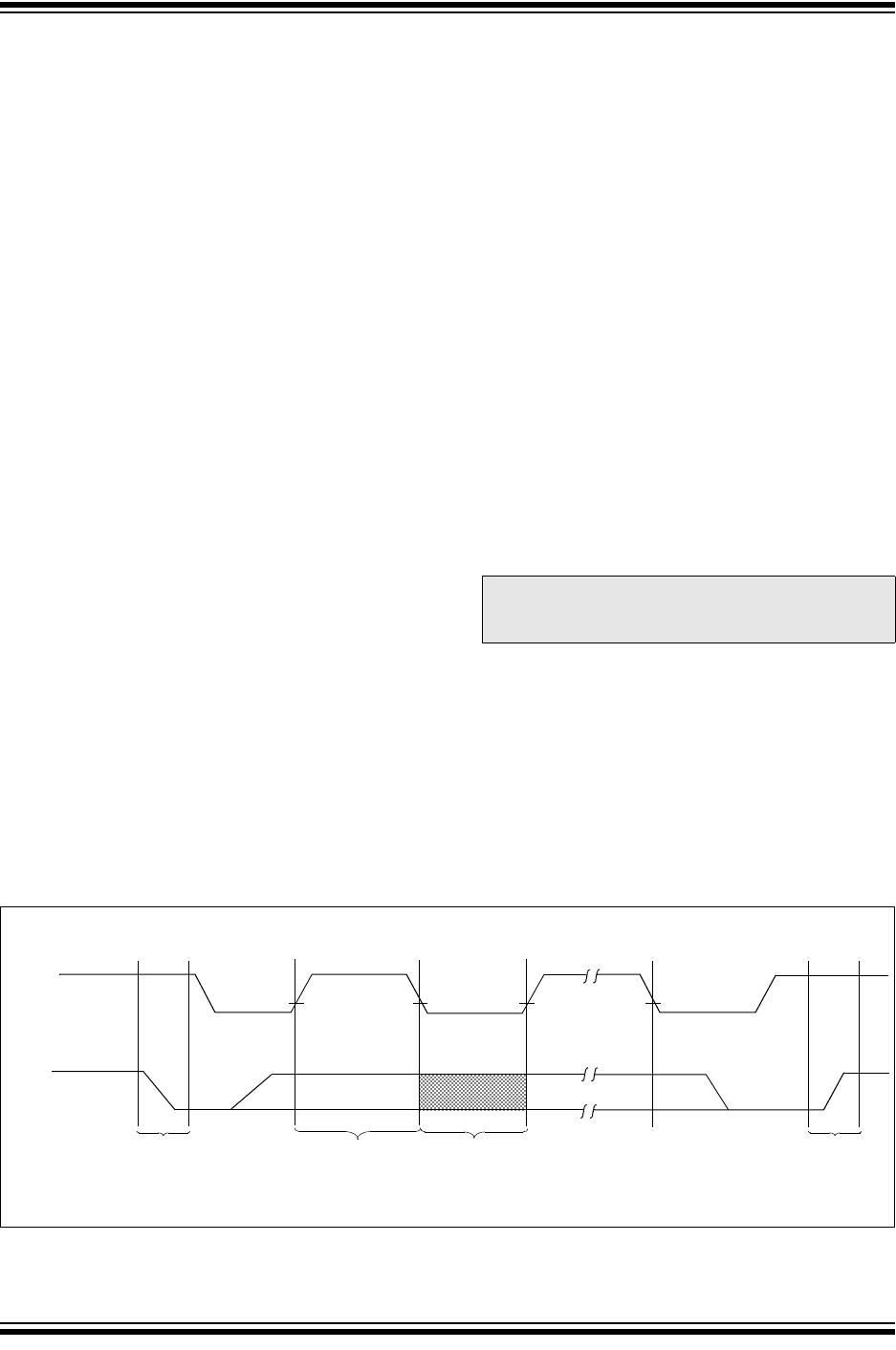

Following the Start condition from the master, the con-

trol code (four bits), the device select (three bits), and

the R/W bit which is a logic low, is placed onto the bus

by the master transmitter. This indicates to the

addressed slave receiver (24XX65) that a byte with a

word address will follow after it has generated an

Acknowledge bit during the ninth clock cycle. There-

fore, the next byte transmitted by the master is the

high-order byte of the word address and will be written

into the Address Pointer of the 24XX65. The next byte

is the Least Significant Address Byte. After receiving

another Acknowledge signal from the 24XX65, the

master device will transmit the data word to be written

into the addressed memory location. The 24XX65

acknowledges again and the master generates a Stop

condition. This initiates the internal write cycle, and

during this time the 24XX65 will not generate

Acknowledge signals (Figure 4-1).

4.2 Page Write

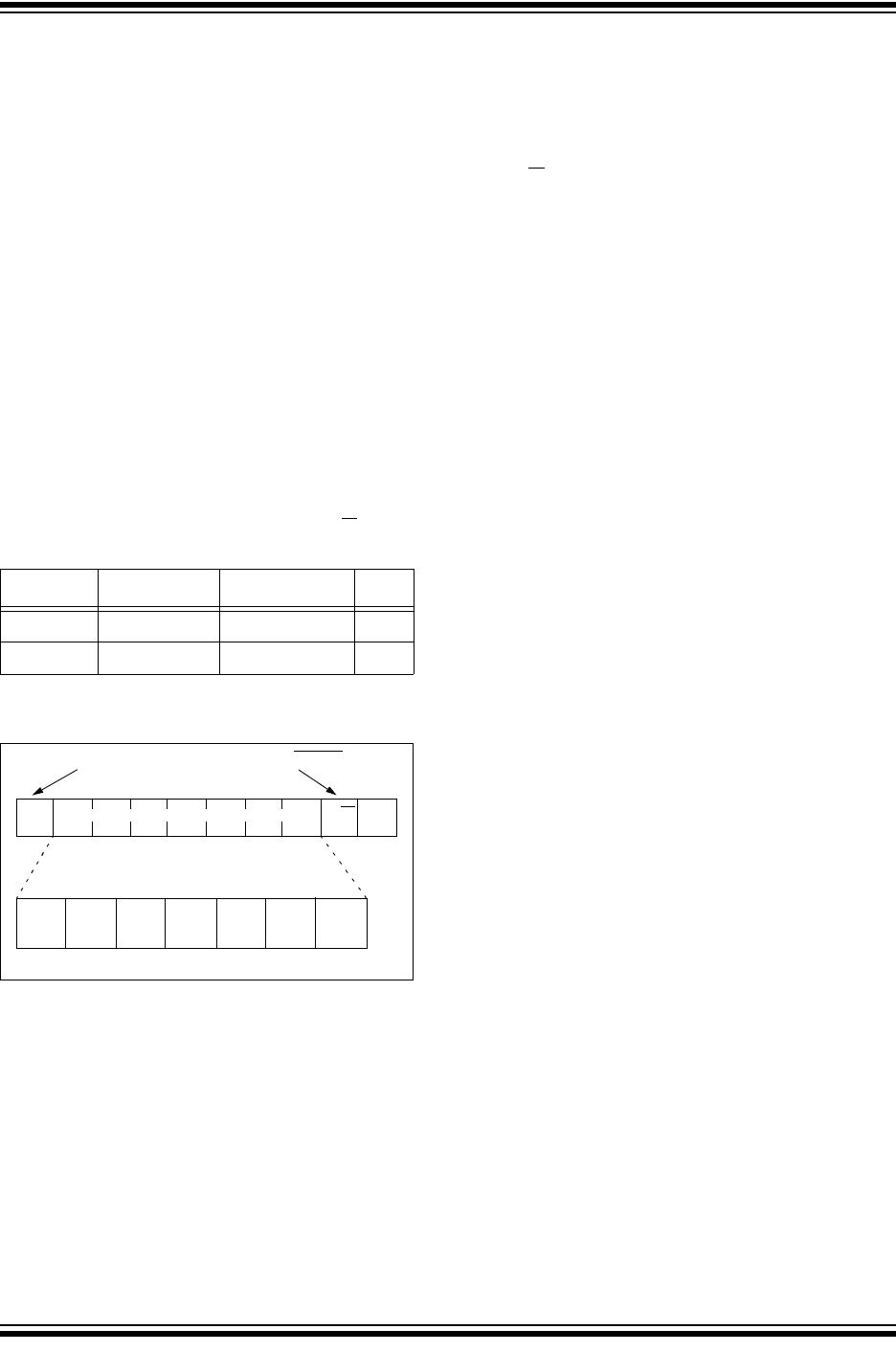

The write control byte, word address and the first data

byte are transmitted to the 24XX65 in the same way as

in a byte write. But instead of generating a Stop

condition, the master transmits up to eight pages of

eight data bytes each (64 bytes total), which are

temporarily stored in the on-chip page cache of the

24XX65. They will be written from the cache into the

EEPROM array after the master has transmitted a Stop

condition. After the receipt of each word, the six lower

order Address Pointer bits are internally incremented by

one. The higher order seven bits of the word address

remain constant. If the master should transmit more

than eight bytes prior to generating the Stop condition

(writing across a page boundary), the address counter

(lower three bits) will roll over and the pointer will be

incremented to point to the next line in the cache. This

can continue to occur up to eight times or until the cache

is full, at which time a Stop condition should be

generated by the master. If a Stop condition is not

received, the cache pointer will roll over to the first line

(byte 0) of the cache, and any further data received will

overwrite previously captured data. The Stop condition

can be sent at any time during the transfer. As with the

byte write operation, once the Stop condition is received

an internal write cycle will begin. The 64-byte cache will

continue to capture data until a Stop condition occurs or

the operation is aborted (Figure 4-2).

Operation Control Code Device Select R/W

Read 1010 Device Address 1

Write 1010 Device Address 0

SLAVE ADDRESS

1010A2 A1 A0

R/W A

START READ/WRITE