8308I Data Sheet

©2015 Integrated Device Technology, Inc December 10, 201510

APPLICATION INFORMATION

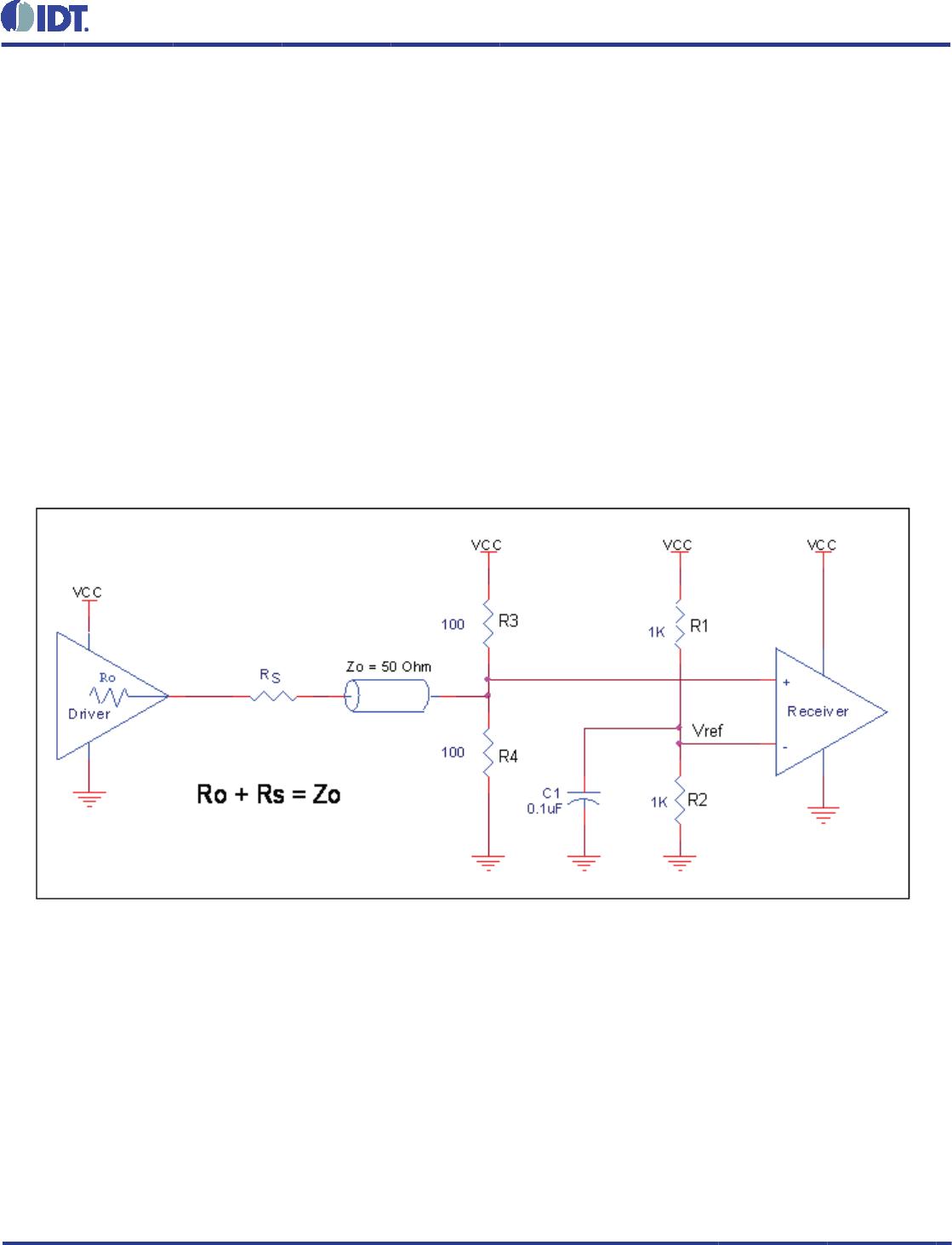

Figure 1 shows how a differential input can be wired to accept single

ended levels. The reference voltage V

REF

= V

DD

/2 is generated by

the bias resistors R1 and R2. The bypass capacitor (C1) is used to

help fi lter noise on the DC bias. This bias circuit should be located

as close to the input pin as possible. The ratio of R1 and R2 might

need to be adjusted to position the V

REF

in the center of the input

voltage swing. For example, if the input clock swing is 2.5V and V

DD

= 3.3V, R1 and R2 value should be adjusted to set V

REF

at 1.25V.

The values below are for when both the single-ended swing and V

DD

are at the same voltage. This confi guration requires that the sum of

the output impedance of the driver (Ro) and the series resistance

(Rs) equals the transmission line impedance. In addition, matched

termination at the input will attenuate the signal in half. This can be

done in one of two ways. First, R3 and R4 in parallel should equal the

FIGURE 1. RECOMMENDED SCHEMATIC FOR WIRING A DIFFERENTIAL INPUT TO ACCEPT SINGLE-ENDED LEVELS

WIRING THE DIFFERENTIAL INPUT TO ACCEPT SINGLE ENDED LEVELS

transmission line impedance. For most 50 applications, R3 and R4

can be 100Ω. The values of the resistors can be increased to reduce

the loading for slower and weaker LVCMOS driver. When using

single ended signaling, the noise rejection benefi ts of differential

signaling are reduced. Even though the differential input can handle

full rail LVCMOS signaling, it is recommended that the amplitude

be reduced. The datasheet specifi es a lower differential amplitude,

however this only applies to differential signals. For single-ended

applications, the swing can be larger, however V

IL

cannot be less

than -0.3V and V

IH

cannot be more than V

DD

+ 0.3V. Though some of

the recommended components might not be used, the pads should

be placed in the layout. They can be utilized for debugging purposes.

The datasheet specifi cations are characterized and guaranteed by

using a differential signal.