LTC4213

17

4213f

The selected MOSFET V

GS

absolute maximum rating should

meet the LTC4213 maximum ∆V

GSMAX

of 8V.

Other MOSFET criteria such as V

BDSS

, I

DMAX

, and R

DSON

should be reviewed. Spikes and ringing above maximum

operating voltage should be considered when choosing

V

BDSS

. I

DMAX

should be greater than the current limit. The

maximum operating load current is determined by the

R

DSON

value. See the section on “Calculating Current

Limit” for details.

Supply Requirements

The LTC4213 can be powered from a single supply or dual

supply system. The load supply is connected to the

SENSEP pin and the drain of the external MOSFET. In the

single supply case, the V

CC

pin is connected to the load

supply, preferably with an RC filter. With dual supplies,

V

CC

is connected to an auxiliary bias supply V

AUX

where

V

AUX

voltage should be greater or equal to the load supply

voltage. The load supply voltage must be capable of

sourcing more current than the circuit breaker limit. If the

load supply current limit is below the circuit breaker trip

current, the LTC4213 may not react when the output

overloads. Furthermore, output overloads may trigger

UVLO if the load supply has foldback current limit in a

single supply system.

V

IN

Transient and Overvoltage Protection

Input transient spikes are commonly observed whenever

the LTC4213 responds to overload. These spikes can be

large in amplitude, especially given that large decoupling

capacitors are absent in hot swap environments. These

short spikes can be clipped with a transient suppressor of

adequate voltage and power rating. In addition, the LTC4213

can detect a prolonged overvoltage condition. When

APPLICATIO S I FOR ATIO

WUU

U

point 6 should be within the circuit breaker limits. Other-

wise, the system fails to start and the circuit breaker trips

immediately after arming. In most applications additional

external gate capacitance is not required unless C

LOAD

is

large and startup becomes problematic. If an external gate

capacitor is employed, its capacitance value should not be

excessive unless it is used with a series resistor. This is

because a big gate capacitor without resistor slows down

the GATE turn off during a fault. An alternative method

would be a stepped I

SEL

pin to allow a higher current limit

during startup.

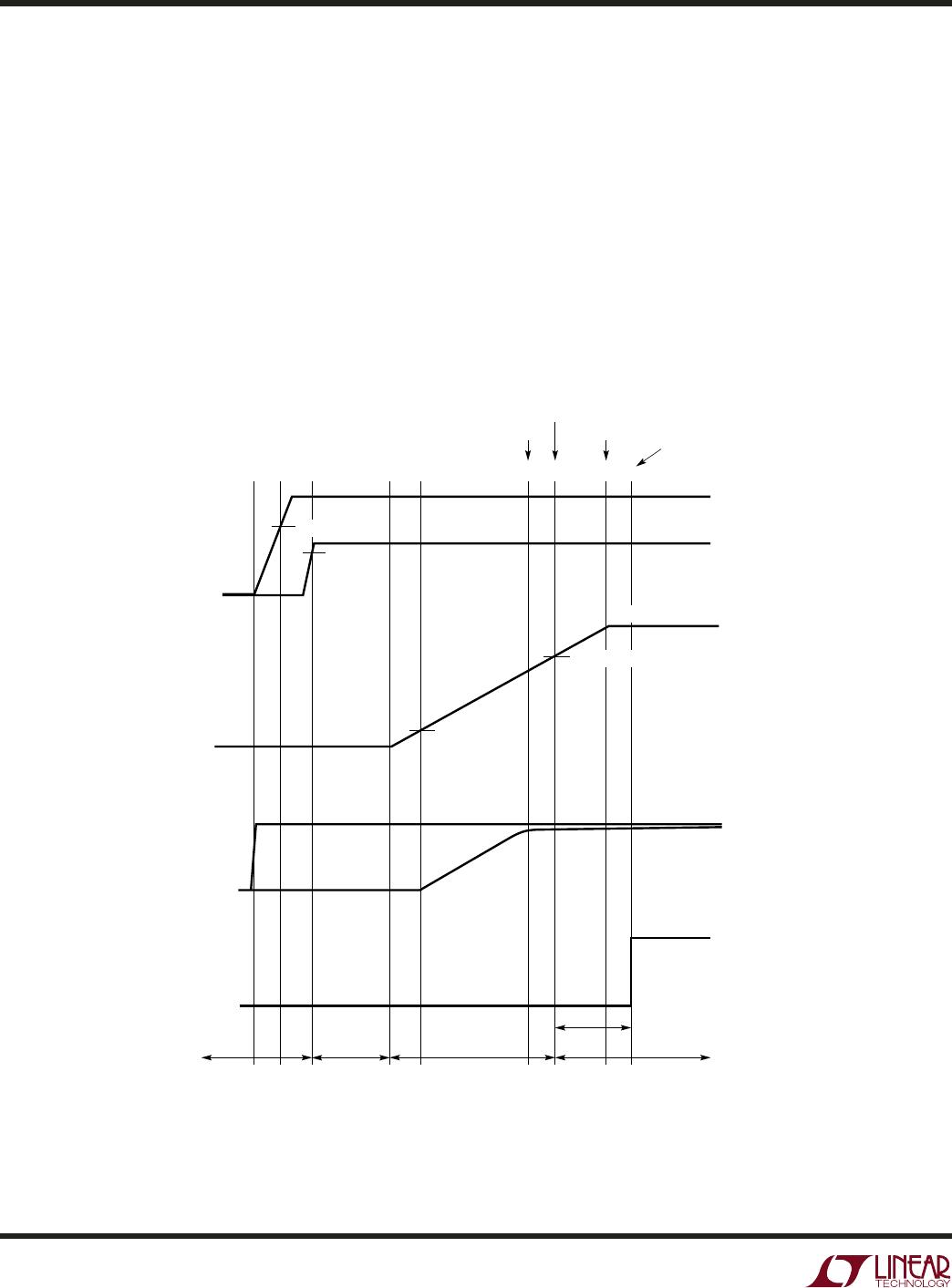

In the event of output short circuit or a severe overload, the

load supply can collapse during GATE ramp up due to load

supply current limit. The chosen MOSFET must withstand

this possible brief short circuit condition before time

point 6 where the circuit breaker is allowed to trip. Bench

short circuit evaluation is a practical verification of a

reliable design. To have current limit while powering a

MOSFET into short circuit conditions, it is preferred that

the load supply sequences to turn on after the circuit

breaker is armed as described in an earlier section.

Power-Off Cycle

The system can be powered off by toggling the ON pin low.

When ON is brought below 0.76V for 5µs, the GATE and

READY pins are pulled low. The system resets when ON is

brought below 0.4V for 80µs.

MOSFET Selection

The LTC4213 is designed to be used with logic (5V) and

sub-logic (3V) MOSFETs for V

CC

potentials above 2.97V

with ∆V

GSMAX

exceeding 4.5V. For a V

CC

supply range

between 2.3V and 2.97V, sub-logic MOSFETs should be

used as the minimum ∆V

GSMAX

is less than 4.5V.