LT3757/LT3757A

17

3757afd

applicaTions inForMaTion

For the bulk C component, which also contributes 1% to

the total ripple:

C

OUT

≥

I

O(MAX)

0.01• V

OUT

• f

The output capacitor in a boost regulator experiences high

RMS ripple currents, as shown in Figure 6. The RMS ripple

current rating of the output capacitor can be determined

using the following equation:

I

RMS(COUT)

≥I

O(MAX)

•

D

MAX

1− D

MAX

Multiple capacitors are often paralleled to meet ESR

requirements. Typically, once the ESR requirement is

satisfied, the capacitance is adequate for filtering and has

the required RMS current rating. Additional ceramic capaci-

tors in parallel are commonly used to reduce the effect of

parasitic inductance in the output capacitor, which reduces

high frequency switching noise on the converter output.

Boost Converter: Input Capacitor Selection

The input capacitor of a boost converter is less critical

than the output capacitor, due to the fact that the inductor

is in series with the input, and the input current wave-

form is continuous. The input voltage source impedance

determines the size of the input capacitor, which is typi-

cally in the range of 10µF to 100µF. A low ESR capacitor

is recommended, although it is not as critical as for the

output capacitor.

The RMS input capacitor ripple current for a boost con-

verter is:

I

RMS(CIN)

= 0.3 • ∆I

L

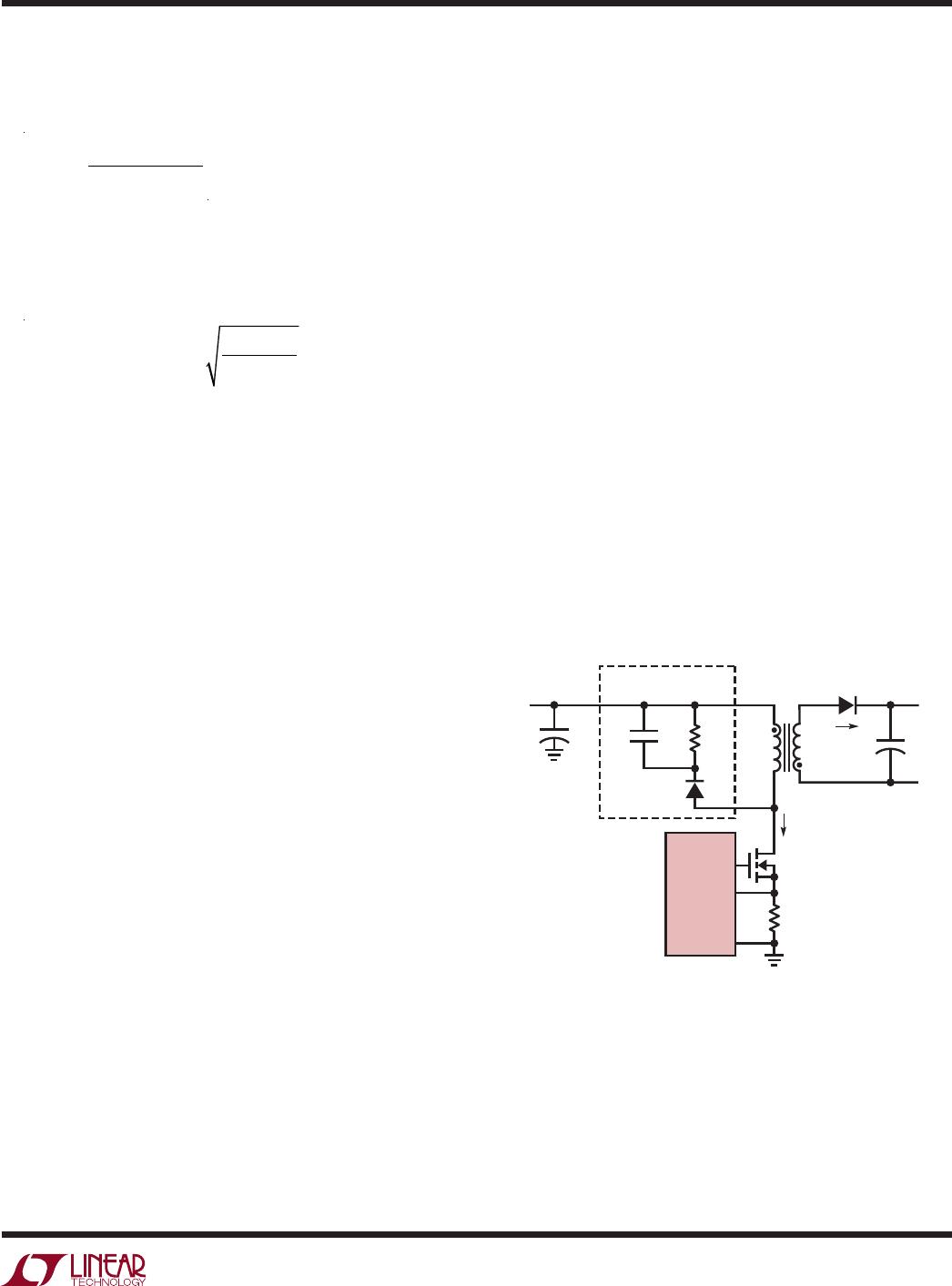

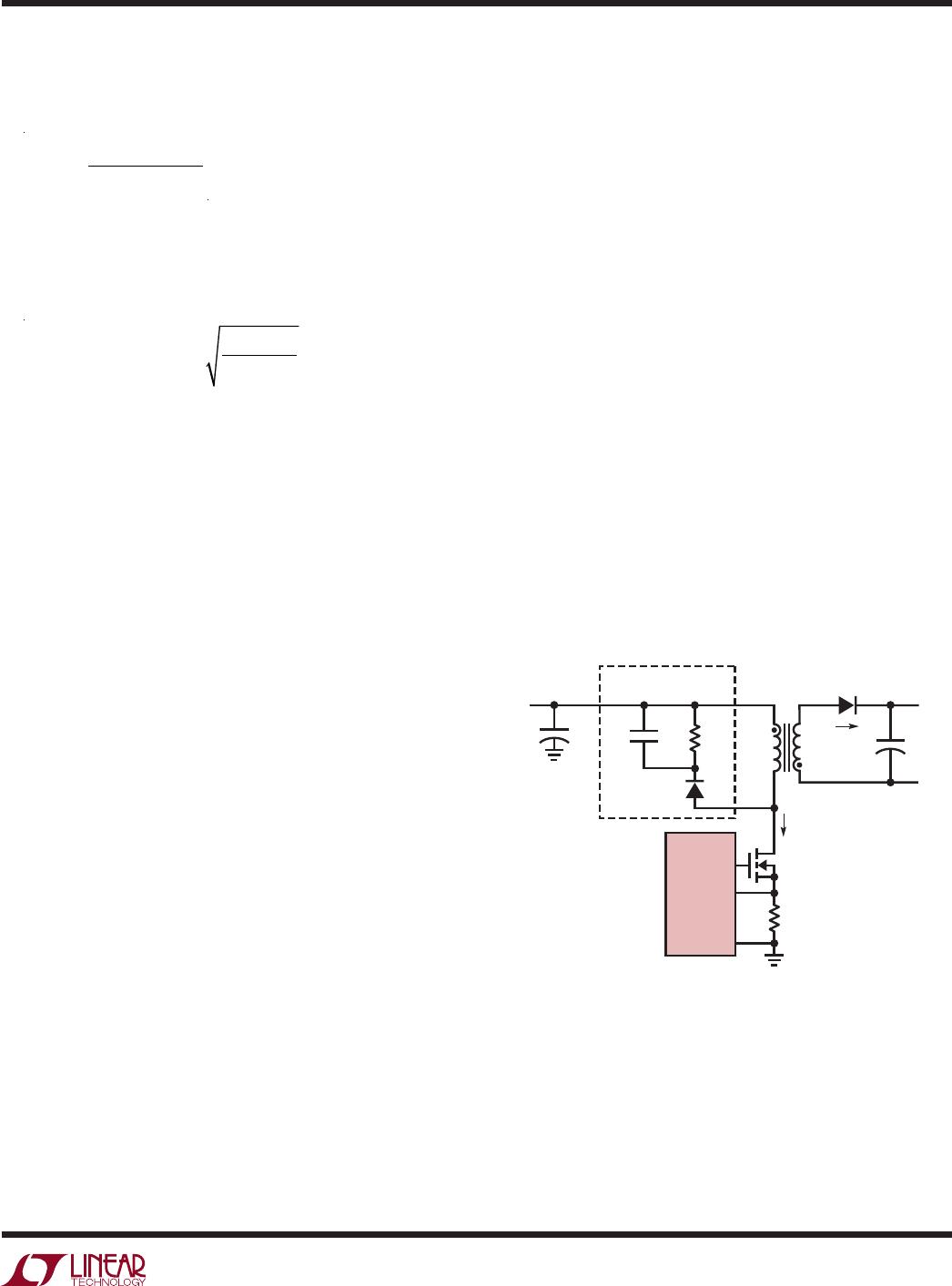

FLYBACK CONVERTER APPLICATIONS

The LT3757 can be configured as a flyback converter

for the applications where the converters have multiple

outputs, high output voltages or isolated outputs. Figure

7 shows a simplified flyback converter.

The flyback converter has a very low parts count for mul-

tiple

outputs, and with prudent selection of turns ratio, can

have high output/input voltage conversion ratios with a

desirable duty cycle. However, it has low efficiency due to

the high peak currents, high peak voltages and consequent

power loss. The flyback converter is commonly used for

an output power of less than 50W.

The flyback converter can be designed to operate either

in continuous or discontinuous mode. Compared to con-

tinuous mode, discontinuous mode has the advantage of

smaller transformer inductances and easy loop compen-

sation, and the disadvantage of higher peak-to-average

current and lower efficiency. In the high output voltage

applications, the flyback converters can be designed

to operate in discontinuous mode to avoid using large

transformers.

Figure 7. A Simplified Flyback Converter

R

SENSE

N

P

:N

S

V

IN

C

IN

C

SN

V

SN

L

P

D

SUGGESTED

RCD SNUBBER

I

D

I

SW

V

DS

3757 F06

GATE

GND

LT3757

SENSE

L

S

M

+

–

+

–

R

SN

D

SN

–

+

C

OUT