15

FN8172.4

August 29, 2006

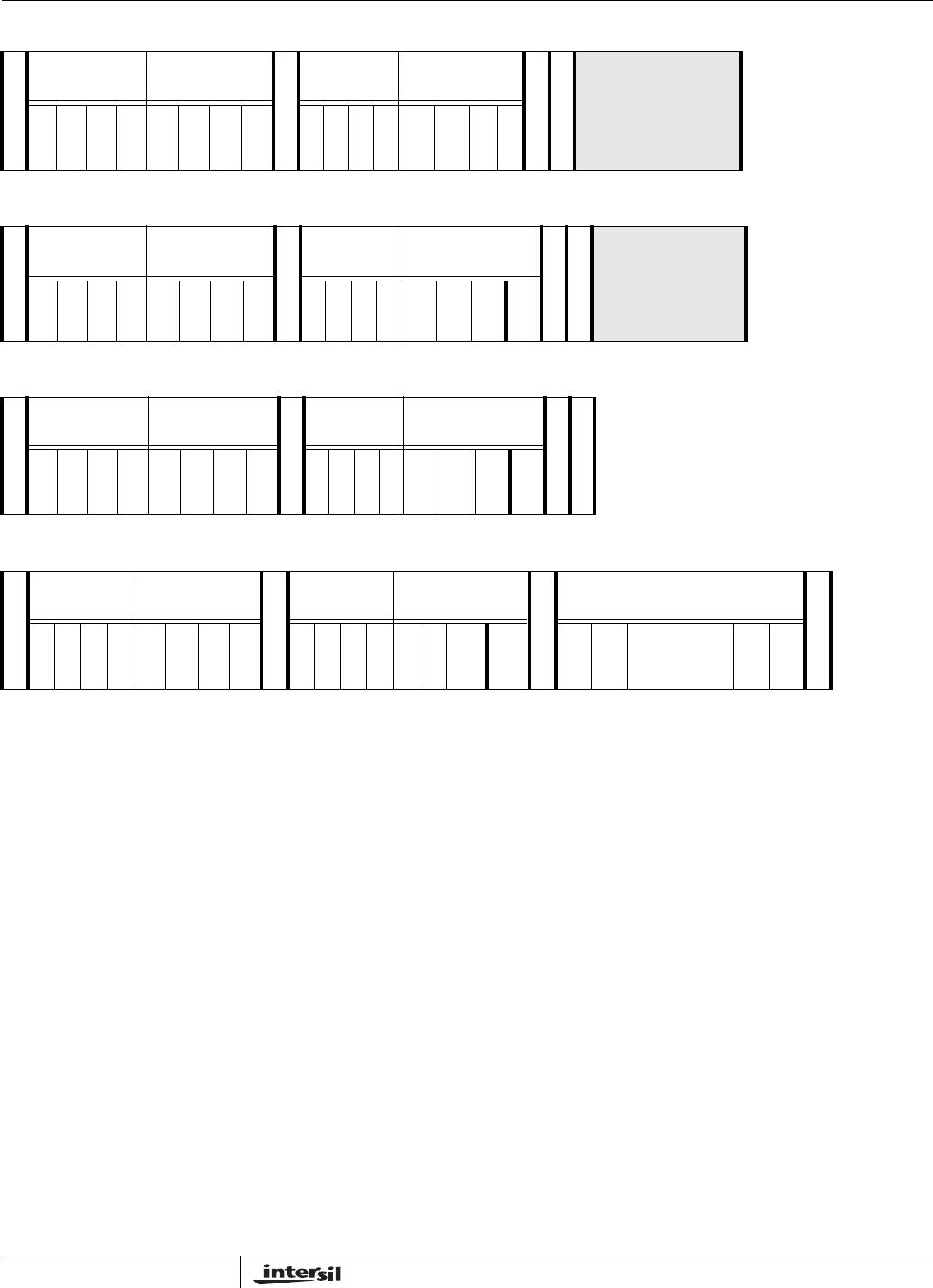

ABSOLUTE MAXIMUM RATINGS

Temperature under bias .................... -65°C to +135°C

Storage temperature ......................... -65°C to +150°C

Voltage on SDA, SCL or any address input

with respect to V

SS

................................. -1V to +7V

Voltage on V+ (referenced to V

SS

)........................ 10V

Voltage on V- (referenced to V

SS

)........................-10V

(V+) - (V-) ..............................................................12V

Any V

H

/R

H

..............................................................V+

Any V

L

/R

L

.................................................................V-

Lead temperature (soldering, 10s) .................. +300°C

I

W

(10s) ..............................................................±6mA

COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only; the functional operation of

the device (at these or any other conditions above

those listed in the operational sections of this

specification) is not implied. Exposure to absolute

maximum rating conditions for extended periods may

affect device reliability.

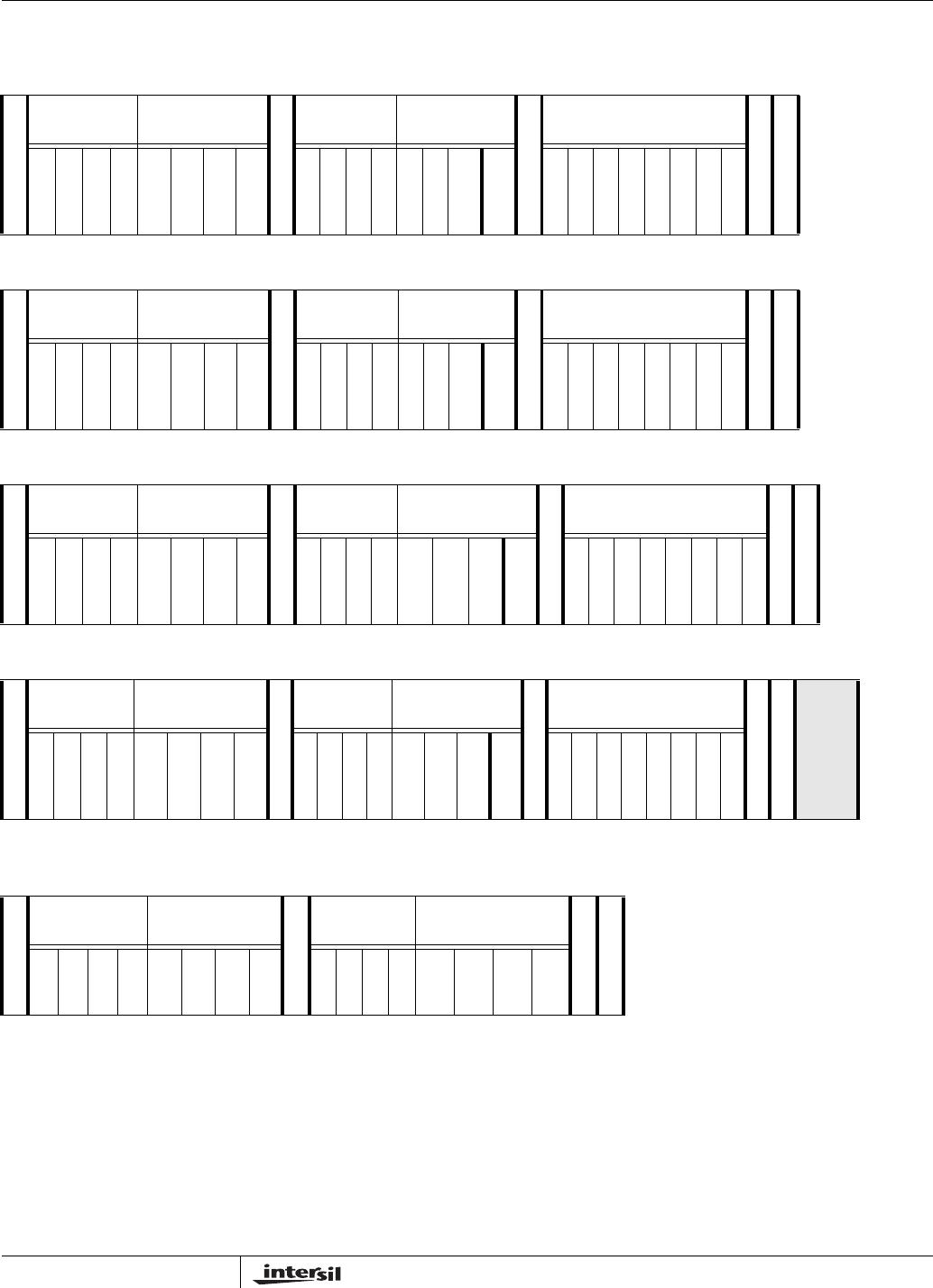

POTENTIOMETER CHARACTERISTICS (Over recommended operating conditions unless otherwise stated.)

Notes: (1) Absolute linearity is utilized to determine actual wiper voltage versus expected voltage as determined by wiper position when used as a

potentiometer.

(2) Relative linearity is utilized to determine the actual change in voltage between two successive tap positions when used as a

potentiometer. It is a measure of the error in step size.

(3) MI = RTOT / 255 or (R

H

- R

L

) / 255, single pot

(4) During power-up V

CC

> V

H

, V

L

, and V

W

.

(5) n = 0, 1, 2, …,255; m =0, 1, 2, …, 254.

RECOMMENDED OPERATING CONDITIONS

Temp Min. Max.

Commercial 0°C+70°C

Industrial -40°C+85°C

Device Supply Voltage (V

CC

)

(4)

Limits

X9268 5V ±10%

X9268-2.7 2.7V to 5.5V

V+ 2.7V to 5.5V

V- -2.7V to -5.5V

Symbol Parameter Test Conditions Min. Typ. Max. Unit

R

TOTAL

End to End Resistance T version 100 kΩ

R

TOTAL

End to EndResistance U version 50 kΩ

End to end resistance tolerance ±20 %

Power rating +25°C, each pot 50 mW

I

W

Wiper current ±3 mA

R

W

Wiper resistance I

W

= ± 1mA, V+ = 3V; V- = -3V 250 Ω

R

W

Wiper resistance I

W

= ± 1mA, V+ = 5V; V- = -5V 150 Ω

V+ Voltage on V+ Pin X9268 +4.5 +5.5 V

X9268-2.7 +2.7 +5.5

V- Voltage on V- Pin X9268 -5.5 -4.5 V

X9268 -2.7 -5.5 -2.7

V

TERM

Voltage on any V

H

/R

H

or V

L

/R

L

pin V- V+ V

Noise Ref: 1kHz -120 dBV

Resolution

(4)

0.4 %

Absolute linearity

(1)

V

w(n)(actual)

- V

w(n)(expected)

±1 MI

(3)

Relative linearity

(2)

V

w(n + 1)

- [V

w(n) + MI

]±0.6MI

(3)

Temperature coefficient of resistance ±300 ppm/°C

Ratiometric Temperature Coefficient ±20 ppm/°C

C

H

/C

L

/C

W

Potentiometer Capacitance See Circuit #3 10/10/25 pF

X9268