Data Sheet AD7873

Rev. F | Page 15 of 28

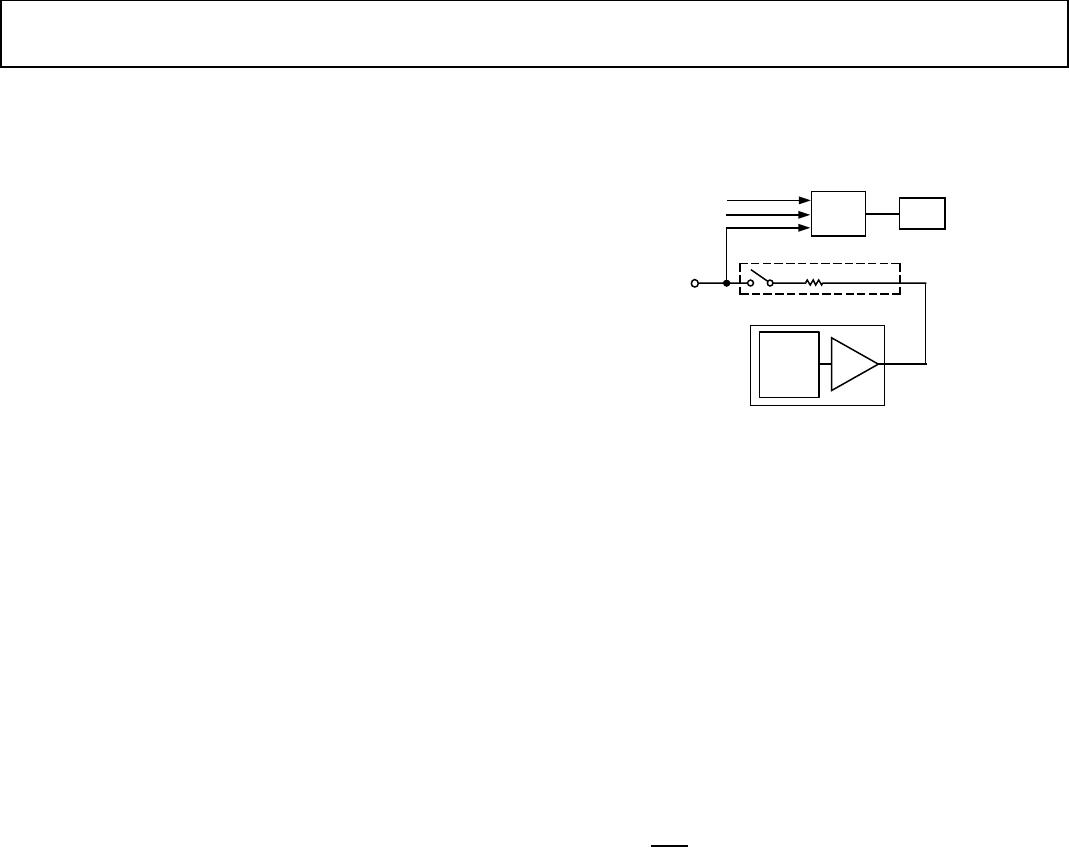

Acquisition Time

The track-and-hold amplifier enters tracking mode on the

falling edge of the fifth DCLK after the start bit is detected (see

Figure 35). The time required for the track-and-hold amplifier

to acquire an input signal depends on how quickly the 37 pF

input capacitance is charged. With zero source impedance on

the analog input, three DCLK cycles are always sufficient to

acquire the signal to the 12-bit level. With a source impedance

(R

IN

) on the analog input, the actual acquisition time required is

calculated using the formula:

( )

pF37Ω1004.8 ×+×=

IN

ACQ

Rt

where R

IN

is the source impedance of the input signal, and 100 Ω,

37 pF is the input RC. Depending on the frequency of DCLK

used, three DCLK cycles may or may not be sufficient to acquire

the analog input signal with various source impedance values.

Touch Screen Settling

In some applications, external capacitors could be required

across the touch screen to filter noise associated with it, for

example, noise generated by the LCD panel or backlight

circuitry. The value of these capacitors causes a settling time

requirement when the panel is touched. The settling time

typically appears as a gain error. There are several methods for

minimizing or eliminating this issue. The problem can be that

the input signal, reference, or both, have not settled to their

final value before the sampling instant of the ADC. Additionally,

the reference voltage could still be changing during the conversion

cycle. One option is to stop or slow down the DCLK for the

required touch screen settling time. This allows the input and

reference to stabilize for the acquisition time, resolving the issue

for both single-ended and differential modes.

The other option is to operate the AD7873 in differential mode

only for the touch screen, and program the AD7873 to keep

the touch screen drivers on and not go into power-down

(PD0 = PD1 = 1). Several conversions could be required,

depending on the settling time required and the AD7873 data

rate. Once the required number of conversions have been made,

the AD7873 can then be placed in a power-down state on the

last measurement. The last method is to use the 15-DCLK cycle

mode, maintaining the touch screen drivers on until it is

commanded by the processor to stop.

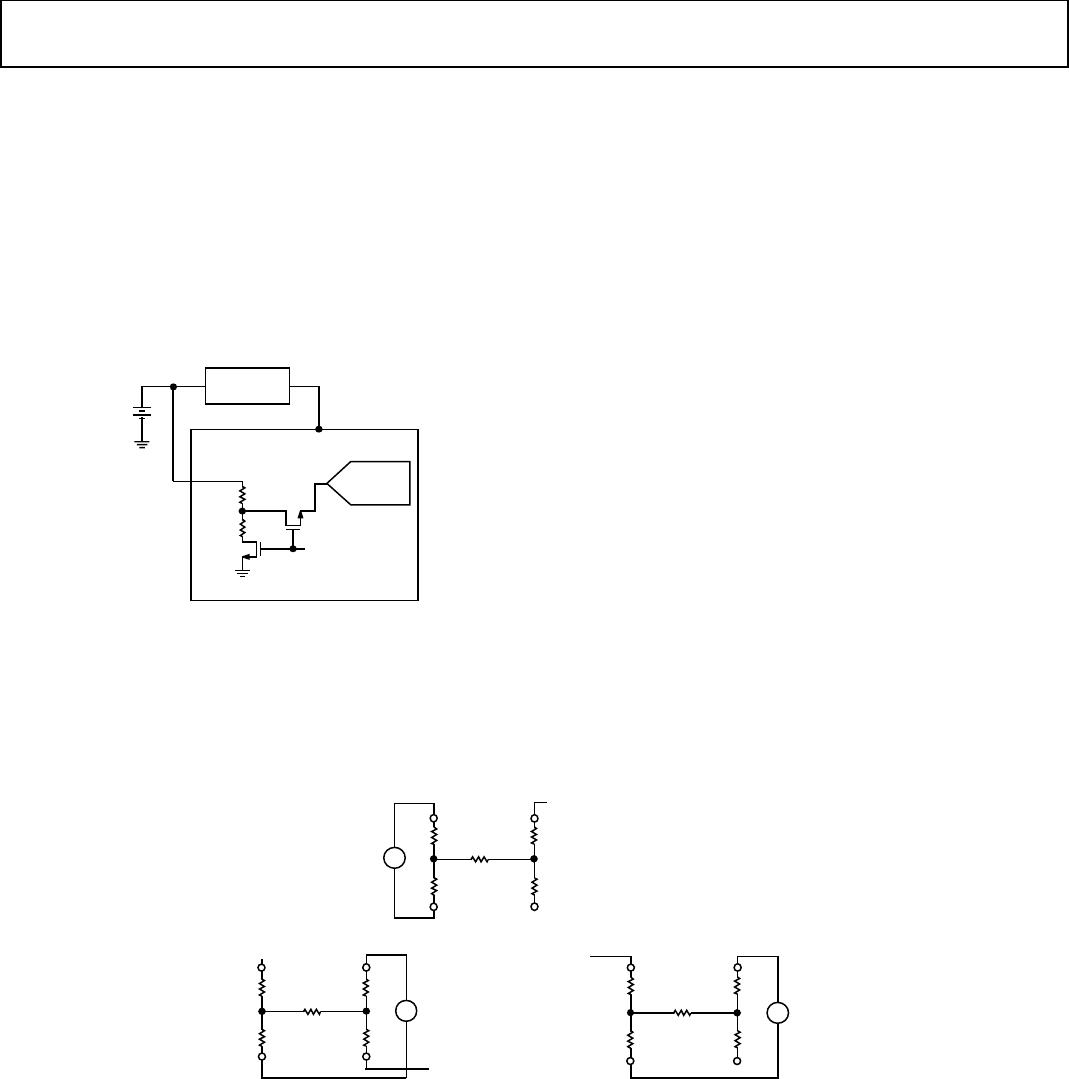

Internal Reference

The AD7873 has an internal reference voltage of 2.5 V. The

internal reference is available on the V

REF

pin for external use in

the system; however, it must be buffered before it is applied

elsewhere. The on-chip reference can be turned on or off with

the power-down address, PD1 = 1 (see Table 8 and Figure 27).

Typically, the reference voltage is only used in single-ended

mode for battery monitoring, temperature measurement, and

for using the auxiliary input. Optimal touch screen performance

is achieved when using the differential mode. The power-up

time of the 2.5 V reference is typically 10 µs without a load;

however, a 0.1 µF capacitor on the V

REF

pin is recommended for

optimum performance because it affects the power-up time (see

Figure 20).

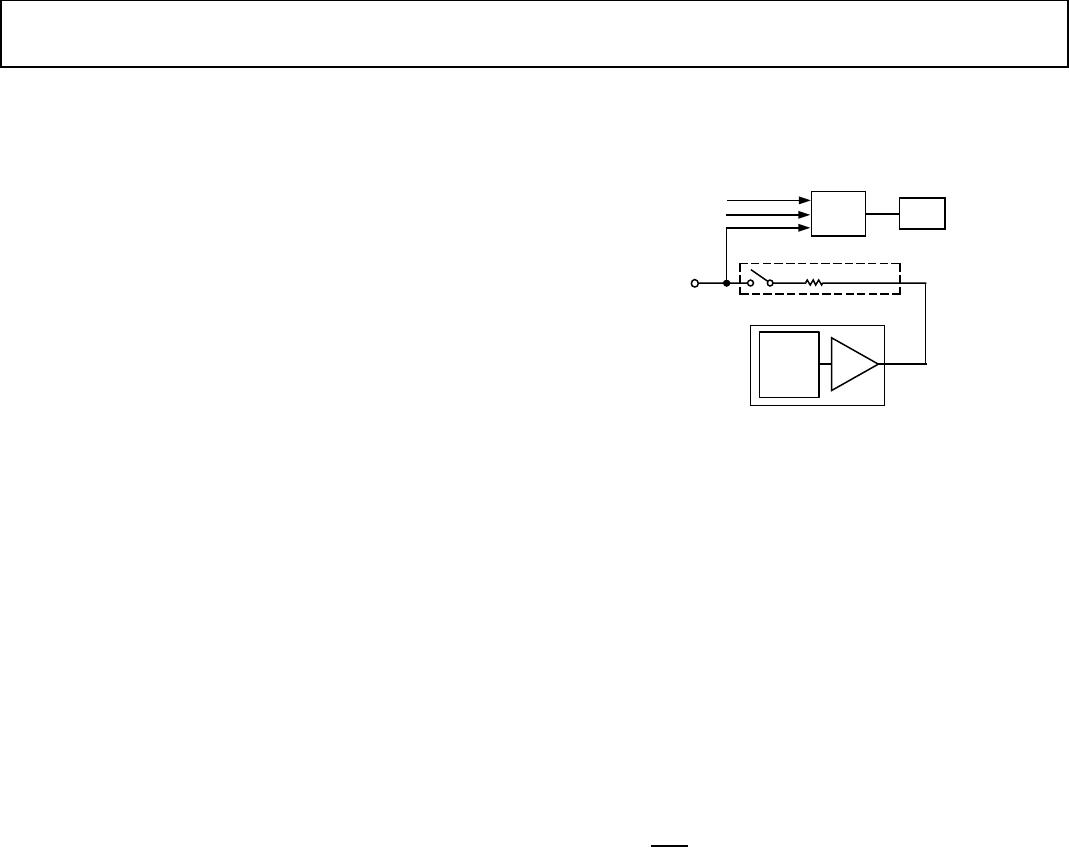

Figure 27. On-Chip Reference Circuitry

Reference Input

The voltage difference between +REF and −REF (see Figure 26)

sets the analog input range. The AD7873 operates with a refer-

ence input in the range of 1 V to +V

CC

. Figure 27 shows the

on-chip reference circuitry on the AD7873. The internal

reference on the AD7873 can be overdriven with an external

reference; for best performance, however, the internal reference

should be disabled when an external reference is applied,

because SW1 in Figure 27 opens on the AD7873 when the

internal reference is disabled. The on-chip reference always is

available at the V

REF

pin as long as the reference is enabled. The

input impedance seen at the V

REF

pin is approximately 260 Ω

when the internal reference is enabled. When it is disabled, the

input impedance seen at the V

REF

pin is in the GΩ region.

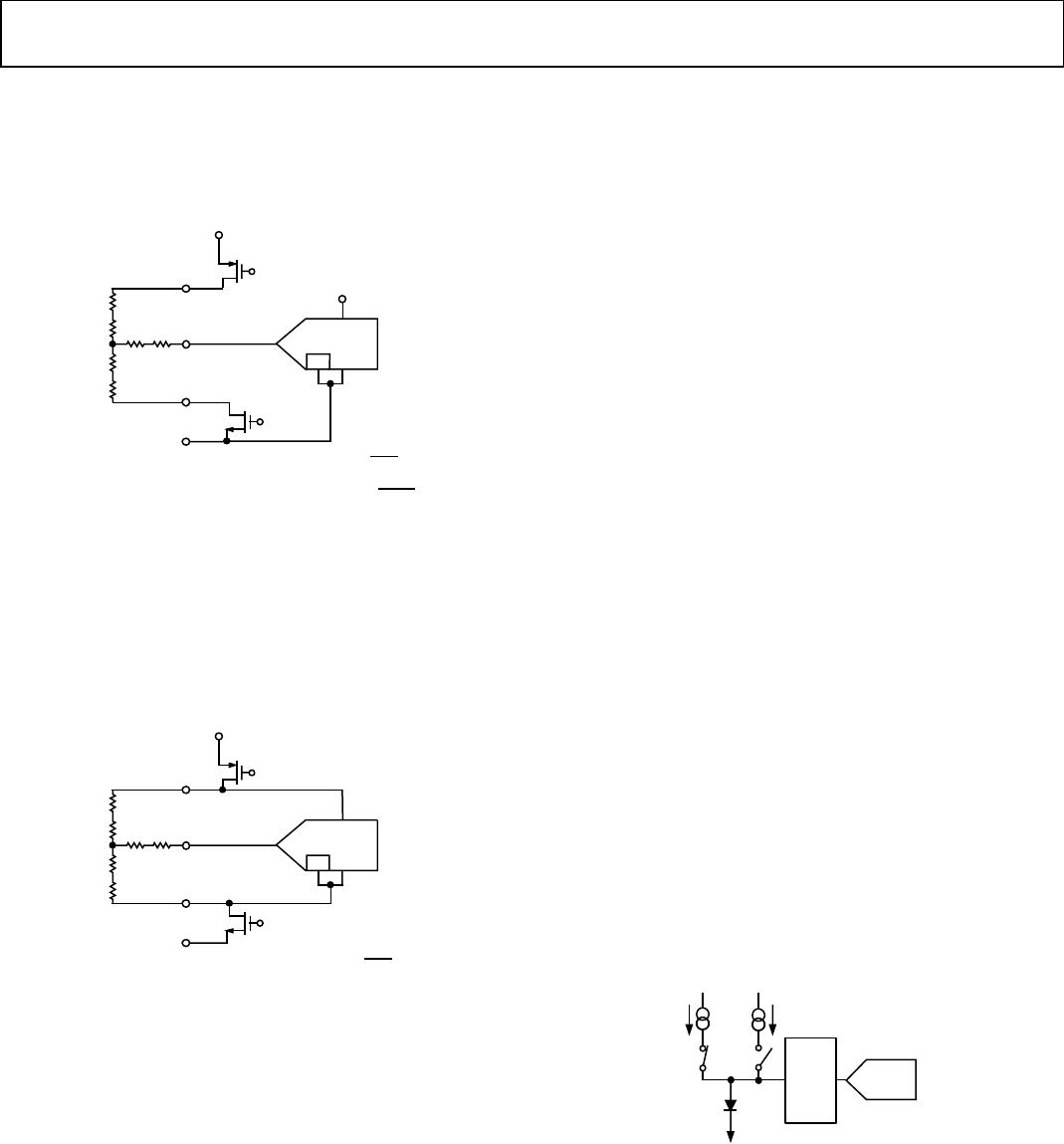

When making touch screen measurements, conversions can be

made in differential (ratiometric) mode or single-ended mode.

If the SER/

DFR

bit is set to 1 in the control register, then a

single-ended conversion is performed. Figure 28 shows the

configuration for a single-ended Y coordinate measurement.

The X+ input is connected to the analog-to-digital converter,

the Y+ and Y− drivers are turned on, and the voltage on X+ is

digitized. The conversion is performed with the ADC referenced

from GND to V

REF

. This V

REF

is either the on-chip reference or

the voltage applied at the V

REF

pin externally, and is determined

by the setting of the power management Bit PD0 and Bit PD1

(see Table 7). The advantage of this mode is that the switches

that supply the external touch screen can be turned off once the

acquisition is complete, resulting in a power savings. However,

the on resistance of the Y drivers affects the input voltage that

can be acquired. The full touch screen resistance could be in the

order of 200 Ω to 900 Ω, depending on the manufacturer. Thus,

if the on resistance of the switches is approximately 6 Ω, true

full-scale and zero-scale voltages cannot be acquired, regardless

of where the pen/stylus is on the touch screen. Note that the

minimum touch screen resistance recommended for use with

X+

Y+

V

REF

260Ω

SW1

3-TO-1

MUX

2.5V

REF

ADC

BUF

02164-027