LT3582/LT3582-5/LT3582-12

19

3582512fb

Maximum Load Currents: Use one of the following equa-

tions to estimate the maximum output load current for the

positive and negative output voltages:

I

OUTP

=

V

IN(MIN)

V

OUTP

⎛

⎝

⎜

⎞

⎠

⎟

• I

PK

–

T

OFF _MIN

•(V

OUTP

+ 0.5 – V

IN(MIN)

)

2•L

⎛

⎝

⎜

⎞

⎠

⎟

•0.8η

or I

OUTN

=

V

IN(MIN)

V

IN(MIN)

+|V

OUTN

|

⎛

⎝

⎜

⎜

⎞

⎠

⎟

⎟

• I

PK

–

T

OFF _MIN

•(|V

OUTN

| +0.5)

2•L

⎛

⎝

⎜

⎞

⎠

⎟

•0.8η

where:

V

OUT

= Regulation voltage

V

IN(MIN)

= Minimum input voltage.

I

PK

= Peak inductor current. See the

Peak

Current Rating

section. Use minimum

I

LIMIT

rating for these calculations.

η = Power conversion effi ciency (about 88%

for Boost or 78% for Inverting)

T

OFF_MIN

= Minimum switch off time. Typically 100ns

for Boost and 125ns for Inverting.

I

OUT

= Output load current

For example, if V

OUTP

= 10V, V

OUTN

= –10V, V

IN

= 5V, and

L = 4.7H then I

OUTP

= 117mA and I

OUTN

= 105mA.

Note: The 155mA (Typ) current limit of the output dis-

connect PMOS (see Electrical Characteristics) may limit

maximum I

OUTP

unless CAPP is shorted to V

OUTP

. See the

Improving Boost Converter Effi ciency

section.

Maximum Slew Rate: Lower inductance causes higher

current slew rates which can lead to current limit over-

shoot. Choose an inductance higher than L

MIN

to limit

the overshoot:

L

MIN

= V

IN(MAX)

• 0.2µH

where V

IN(MAX)

is the maximum input voltage. Using the

previous example V

IN

= 3V, L

MIN

= 0.6H.

Capacitor Selection

The small size and low ESR of ceramic capacitors makes

them suitable for most LT3582 series applications. X5R

and X7R types are recommended because they retain their

capacitance over wider voltage and temperature ranges

than other types such as Y5V or Z5U. A 4.7F input capaci-

tor and a 2.2F to 10F output capacitor are suffi cient for

most LT3582 series applications. Always use a capacitor

with a suffi cient voltage rating. Many capacitors rated at

2.2F to 10F, particularly 0805 or 0603 case sizes, have

greatly reduced capacitance at the desired output voltage.

Generally a 1206 capacitor will be adequate. A 0.22F to

1F capacitor placed on the CAPP node is recommended

to fi lter the inductor current while the larger 2.2F to 10F

placed on the V

OUTP

and V

OUTN

nodes will give excellent

transient response and stability. Avoid placing large value

capacitors (generally > 6.8F) on both CAPP and V

OUTP

.

This confi guration can be less stable since it creates two

poles, one at the CAPP pin and the other at the V

OUTP

pin, which can be near each other in frequency. Table 4

shows a list of several capacitor manufacturers. Consult

the manufacturers for more detailed information and for

their entire selection of related parts.

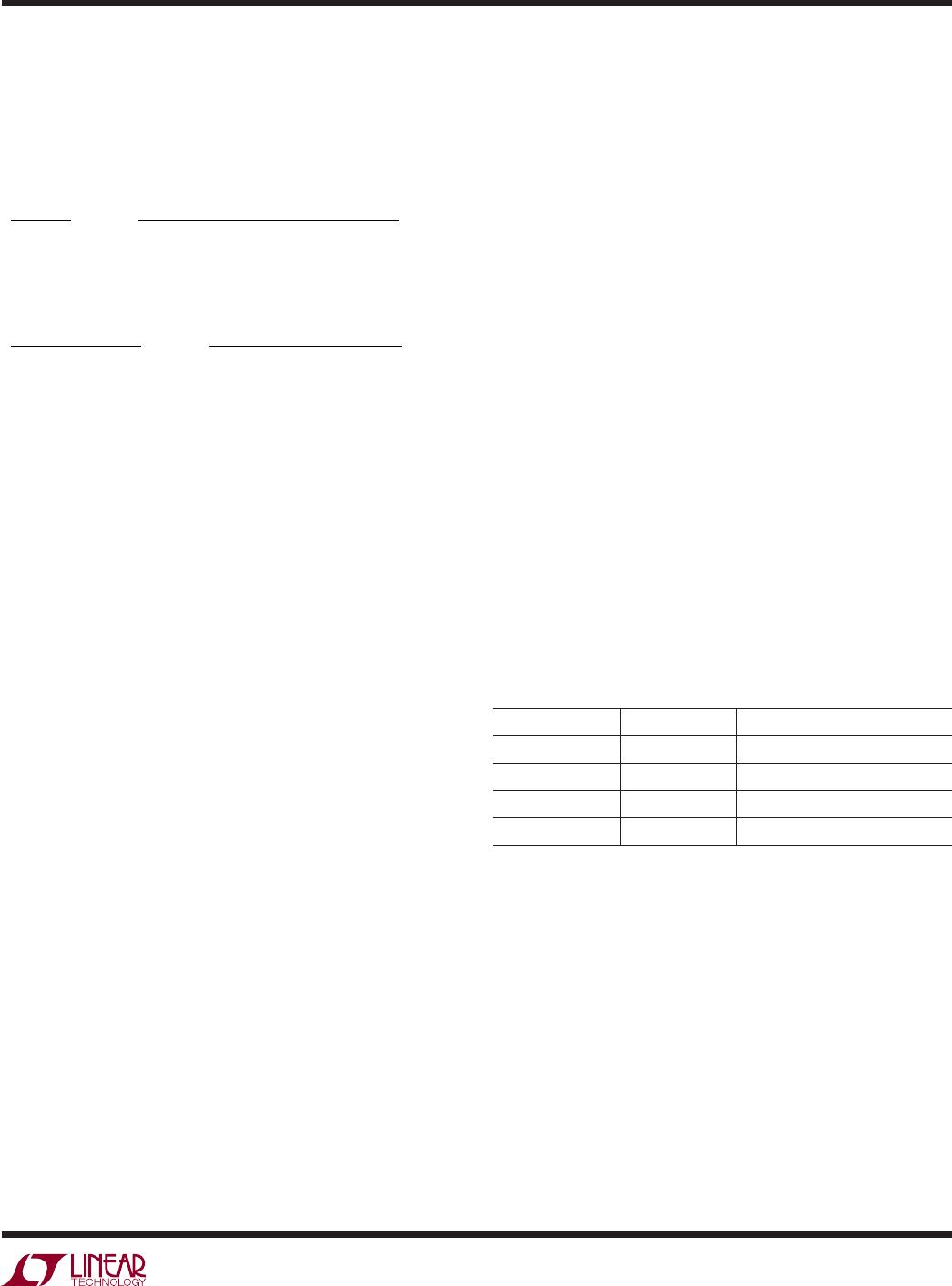

Table 4. Ceramic Capacitor Manufacturers

MANUFACTURER PHONE URL

Kemet 408-986-0424 www.kemet.com

Murata 814-237-1431 www.murata.com

Taiyo Yuden 408-573-4150 www.t-yuden.com

TDK 847-803-6100 www.tdk.com

Diode Selection

Schottky diodes, with their low forward voltage drops and

fast switching speeds, are recommended for use with the

LT3582 series. The Diodes Inc. B0540WS is a very good

choice in a small SOD-323 package. This diode is rated to

handle an average forward current of 500mA and performs

well across a wide temperature range. Schottky diodes

with very low forward voltage drops are also available.

These diodes may improve effi ciency at moderate and cold

temperatures, but will likely reduce effi ciency at higher

temperatures due to excessive reverse leakage currents.

APPLICATIONS INFORMATION