AD7859/AD7859L

REV. A

–21–

CALIBRATION SECTION

Calibration Overview

The automatic calibration that is performed on power-up

ensures that the calibration options covered in this section are

not required in a significant number of applications. A calibra-

tion does not have to be initiated unless the operating condi-

tions change (CLKIN frequency, analog input mode, reference

voltage, temperature, and supply voltages). The AD7859/

AD7859L has a number of calibration features that may be

required in some applications, and there are a number of advan-

tages in performing these different types of calibration. First, the

internal errors in the ADC can be reduced significantly to give

superior dc performance; and second, system offset and gain er-

rors can be removed. This allows the user to remove reference

errors (whether it be internal or external reference) and to make

use of the full dynamic range of the AD7859/AD7859L by ad-

justing the analog input range of the part for a specific system.

There are two main calibration modes on the AD7859/AD7859L,

self-calibration and system calibration. There are various op-

tions in both self-calibration and system calibration as outlined

previously in Table IV. All the calibration functions are initi-

ated by writing to the control register and setting the STCAL

bit to 1.

The duration of each of the different types of calibration is given

in Table IX for the AD7859 with a 4 MHz master clock. These

calibration times are master clock dependent. Therefore the

calibration times for the AD7859L (CLKIN = 1.8 MHz) are

larger than those quoted in Table IX.

Table IX. Calibration Times (AD7859 with 4 MHz CLKIN)

Type of Self-Calibration or System Calibration Time

Full 31.25 ms

Gain + Offset 6.94 ms

Offset 3.47 ms

Gain 3.47 ms

Calibration on Power-On

The calibration on power-on is initiated by the first CONVST

pulse after the AV

DD

and DV

DD

power on. From the CONVST

pulse the part internally sets a 32/72 ms (4 MHz/1.8 MHz

CLKIN) timeout. This time is large enough to ensure that the

internal reference has settled before the calibration is performed.

However, if an external reference is being used, this reference

must have stabilized before the automatic calibration is initiated.

This first

CONVST pulse also triggers the BUSY signal high,

and once the 32/72 ms has elapsed, the BUSY signal goes low.

At this point the next

CONVST pulse that is applied initiates

the automatic full self-calibration. This

CONVST pulse again

triggers the BUSY signal high, and after 32/72 ms (4 MHz/

1.8 MHz CLKIN), the calibration is completed and the BUSY

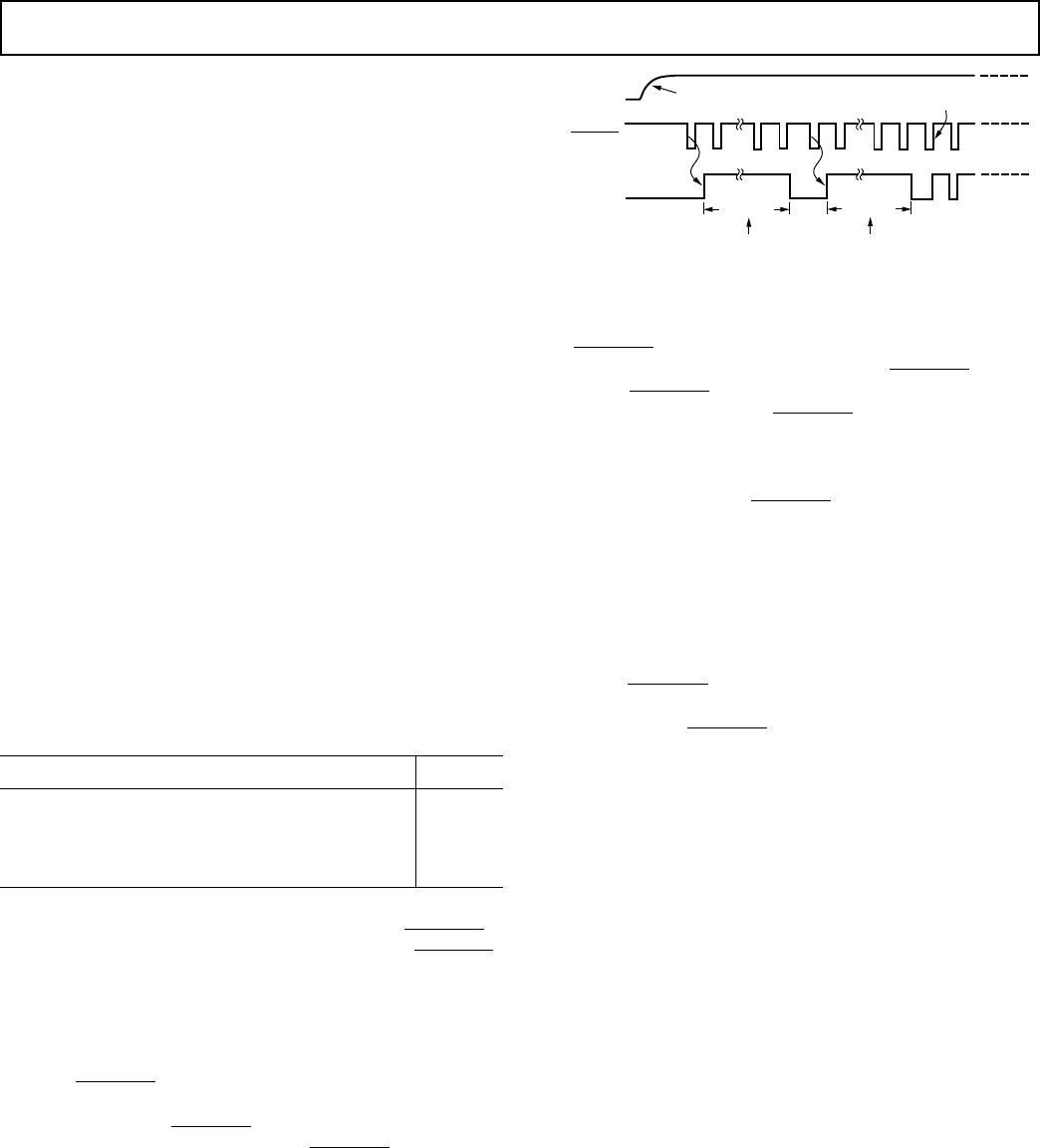

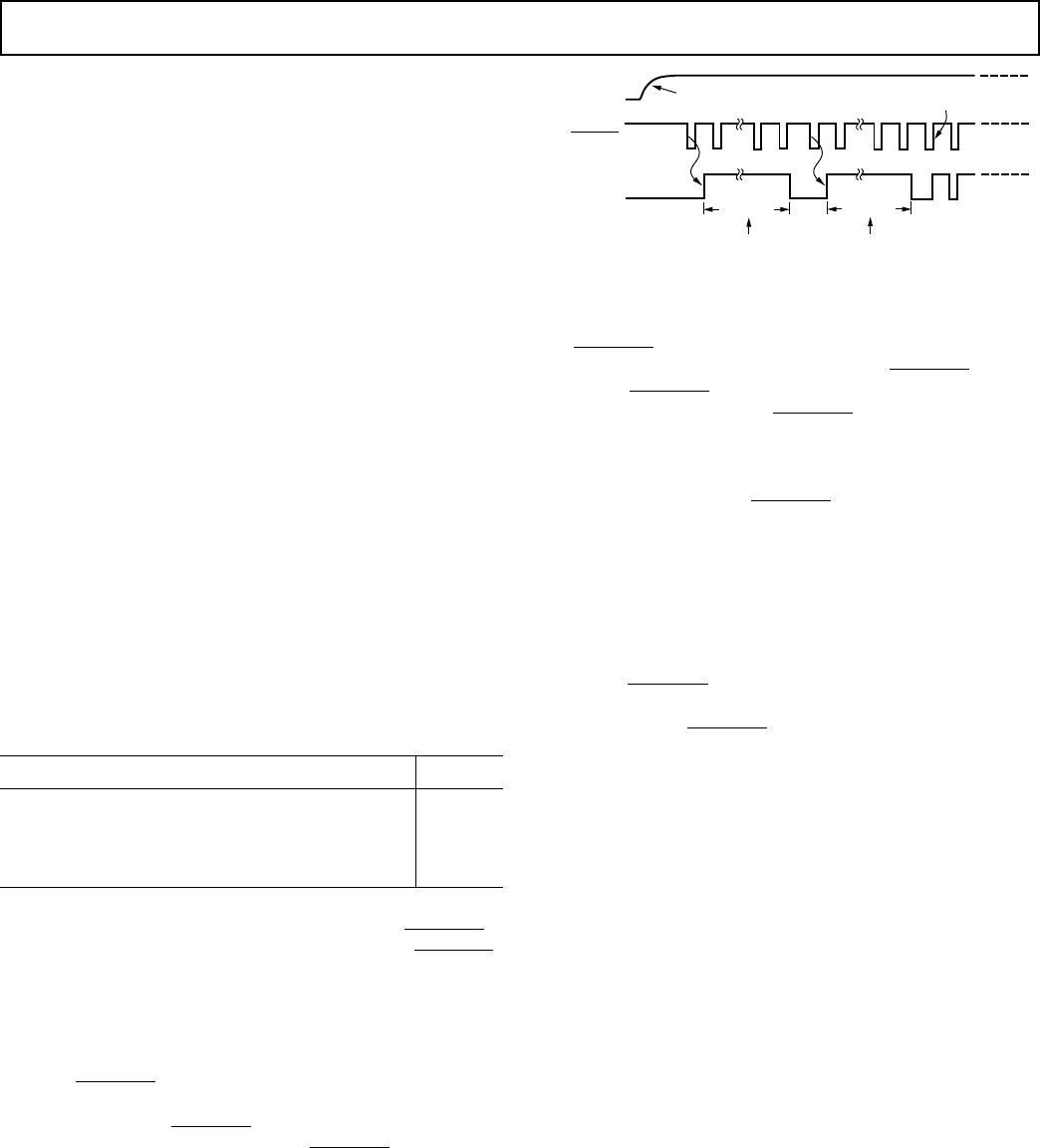

signal goes low. This timing arrangement is shown in Figure 28.

The times in Figure 28 assume a 4 MHz/1.8 MHz CLKIN signal.

AV

DD

= DV

DD

CONVST

BUSY

POWER-ON

32/72ms

32/72ms

TIMEOUT PERIOD AUTOMATIC

CALIBRATION

DURATION

CONVERSION IS INITIATED

ON THIS EDGE

Figure 28. Timing Arrangement for Autocalibration on

Power-On

The CONVST signal is gated with the BUSY internally so that

as soon as the timeout is initiated by the first

CONVST pulse all

subsequent

CONVST pulses are ignored until the BUSY signal

goes low, 32/72 ms later. The

CONVST pulse that follows after

the BUSY signal goes low initiates a full self-calibration. This

takes a further 32/72 ms. After calibration, the part is accurate

to the 12-bit level and the specifications quoted on the data

sheet apply; all subsequent

CONVST pulses initiate conver-

sions. There is no need to perform another calibration unless

the operating conditions change or unless a system calibration is

required.

This autocalibration at power-on is disabled if the user writes to

the control register before the autocalibration is initiated. If the

control register write operation occurs during the first 32/72 ms

timeout period, then the BUSY signal stays high for the 32/72

ms and the

CONVST pulse that follows the BUSY going low

does not initiate a full self-calibration. It initiates a conversion

and all subsequent

CONVST pulses initiate conversions as well.

If the control register write operation occurs when the automatic

full self-calibration is in progress, then the calibration is not be

aborted; the BUSY signal remains high until the automatic full

self-calibration is complete.

Self-Calibration Description

There are four different calibration options within the self-

calibration mode. There is a full self-calibration where the

DAC, internal offset, and internal gain errors are removed.

There is the (Gain + Offset) self-calibration which removes the

internal gain error and then the internal offset errors. The inter-

nal DAC is not calibrated here. Finally, there are the self-offset

and self-gain calibrations which remove the internal offset errors

and the internal gain errors respectively.

The internal capacitor DAC is calibrated by trimming each of

the capacitors in the DAC. It is the ratio of these capacitors to

each other that is critical, and so the calibration algorithm en-

sures that this ratio is at a specific value by the end of the cali-

bration routine. For the offset and gain there are two separate

capacitors, one of which is trimmed during offset calibration

and one of which is trimmed during gain calibration.

In Bipolar Mode the midscale error is adjusted by an offset cali-

bration and the positive full-scale error is adjusted by the gain

calibration. In Unipolar Mode the zero-scale error is adjusted

by the offset calibration and the positive full-scale error is ad-

justed by the gain calibration.