AMIS−30522, NCV70522

http://onsemi.com

11

FUNCTIONAL DESCRIPTION

H−Bridge Drivers

A full H−bridge is integrated for each of the two stator

windings. Each H−bridge consists of two low−side and two

high−side N−type MOSFET switches. Writing logic ‘0’ in

bit <MOTEN> disables all drivers (High−Impedance).

Writing logic ‘1’ in this bit enables both bridges and current

can flow in the motor stator windings.

In order to avoid large currents through the H−bridge

switches, it is guaranteed that the top− and bottom switches

of the same half−bridge are never conductive

simultaneously (interlock delay).

A two−stage protection against shorts on motor lines is

implemented. In a first stage, the current in the driver is

limited. Secondly, when excessive voltage is sensed across

the transistor, the transistor is switched−off.

In order to reduce the radiated/conducted emission,

voltage slope control is implemented in the output switches.

The output slope is defined by the gate−drain capacitance of

output transistor and the (limited) current that drives the

gate. There are two trimming bits for slope control (See

Table 12 SPI Control Parameter Overview EMC[1:0]).

The power transistors are equipped with so−called “active

diodes”: when a current is forced through the transistor

switch in the reverse direction, i.e. from source to drain, then

the transistor is switched on. This ensures that most of the

current flows through the channel of the transistor instead of

through the inherent parasitic drain−bulk diode of the

transistor.

Depending on the desired current range and the

micro−step position at hand, the R

DS(on)

of the low−side

transistors will be adapted such that excellent current−sense

accuracy is maintained. The R

DS(on)

of the high−side

transistors remain unchanged, see also the DC−parameter

table for more details.

PWM Current Control

A PWM comparator compares continuously the actual

winding current with the requested current and feeds back

the information to a digital regulation loop. This loop then

generates a PWM signal, which turns on/off the H−bridge

switches. The switching points of the PWM duty−cycle are

synchronized to the on−chip PWM clock.

The frequency of the PWM controller can be doubled to

reduce the over−all current−ripple with a factor of two.

To further reduce the emission, an artificial jitter can be

added to the PWM frequency. (see Table 12, SPI Control

Register 1). The PWM frequency will not vary with changes

in the supply voltage. Also variations in motor−speed or

load−conditions of the motor have no effect. There are no

external components required to adjust the PWM frequency.

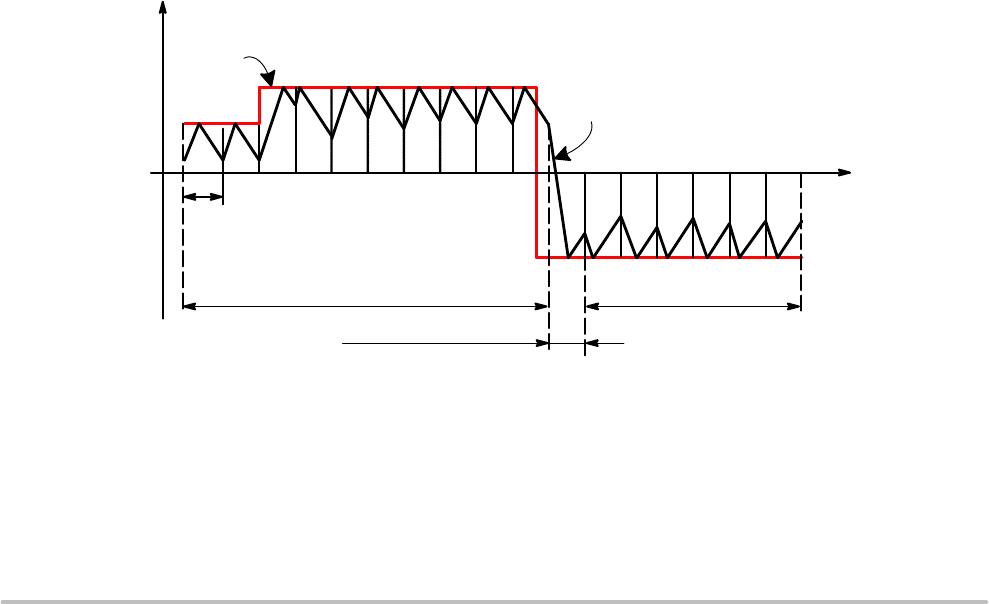

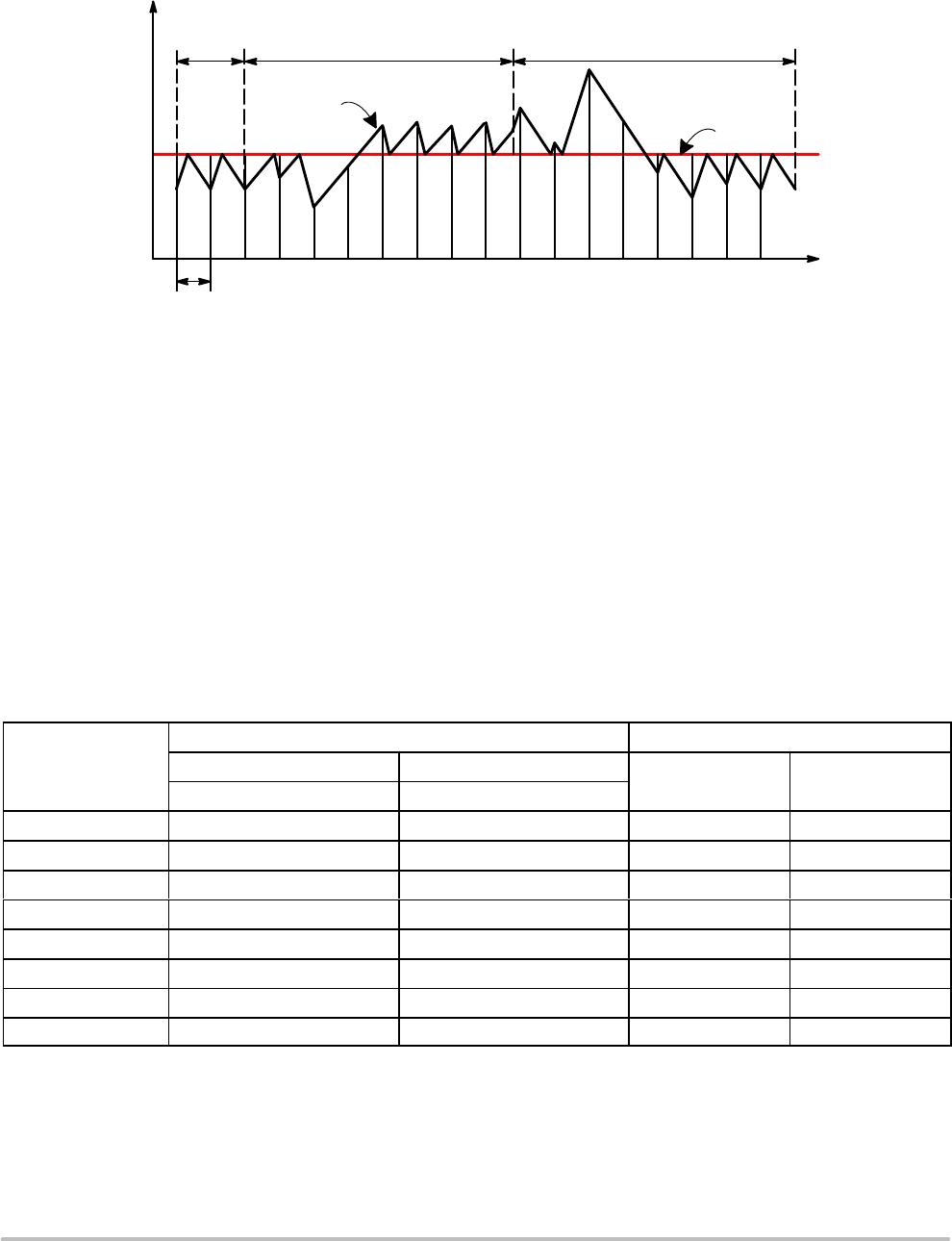

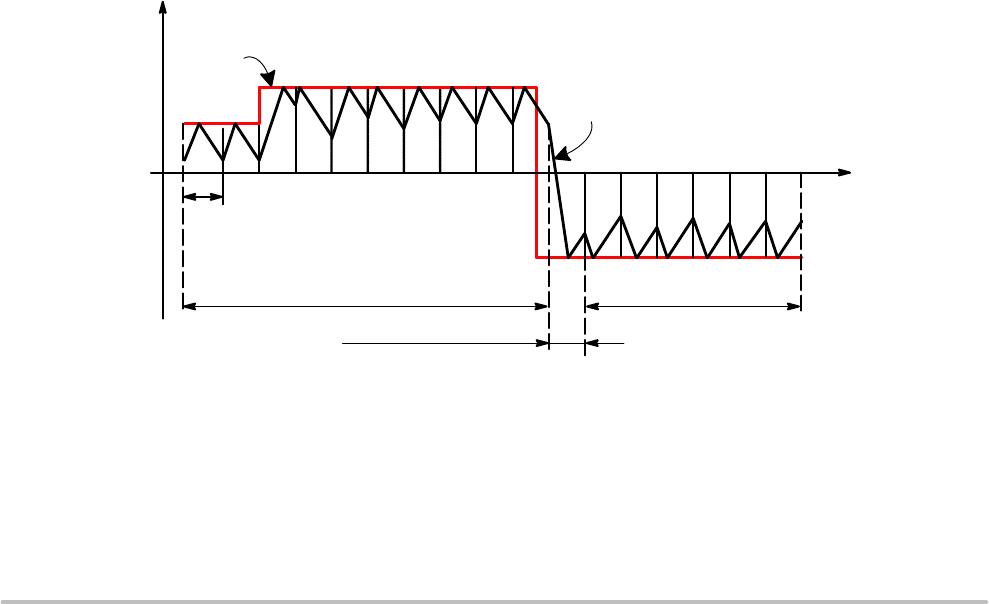

Automatic Forward & Slow−Fast Decay

The PWM generation is in steady−state using a

combination of forward and slow−decay. The absence of

fast−decay in this mode, guarantees the lowest possible

current−ripple “by design”. For transients to lower current

levels, fast−decay is automatically activated to allow

high−speed response. The selection of fast or slow decay is

completely transparent for the user and no additional

parameters are required for operation.

Icoil

0 t

Forward & Slow Decay

Actual value

Set value

Figure 7. Forward & Slow/Fast Decay PWM

T

PWM

Forward & Slow Decay

Fast Decay & Forward