AMIS−30522, NCV70522

http://onsemi.com

18

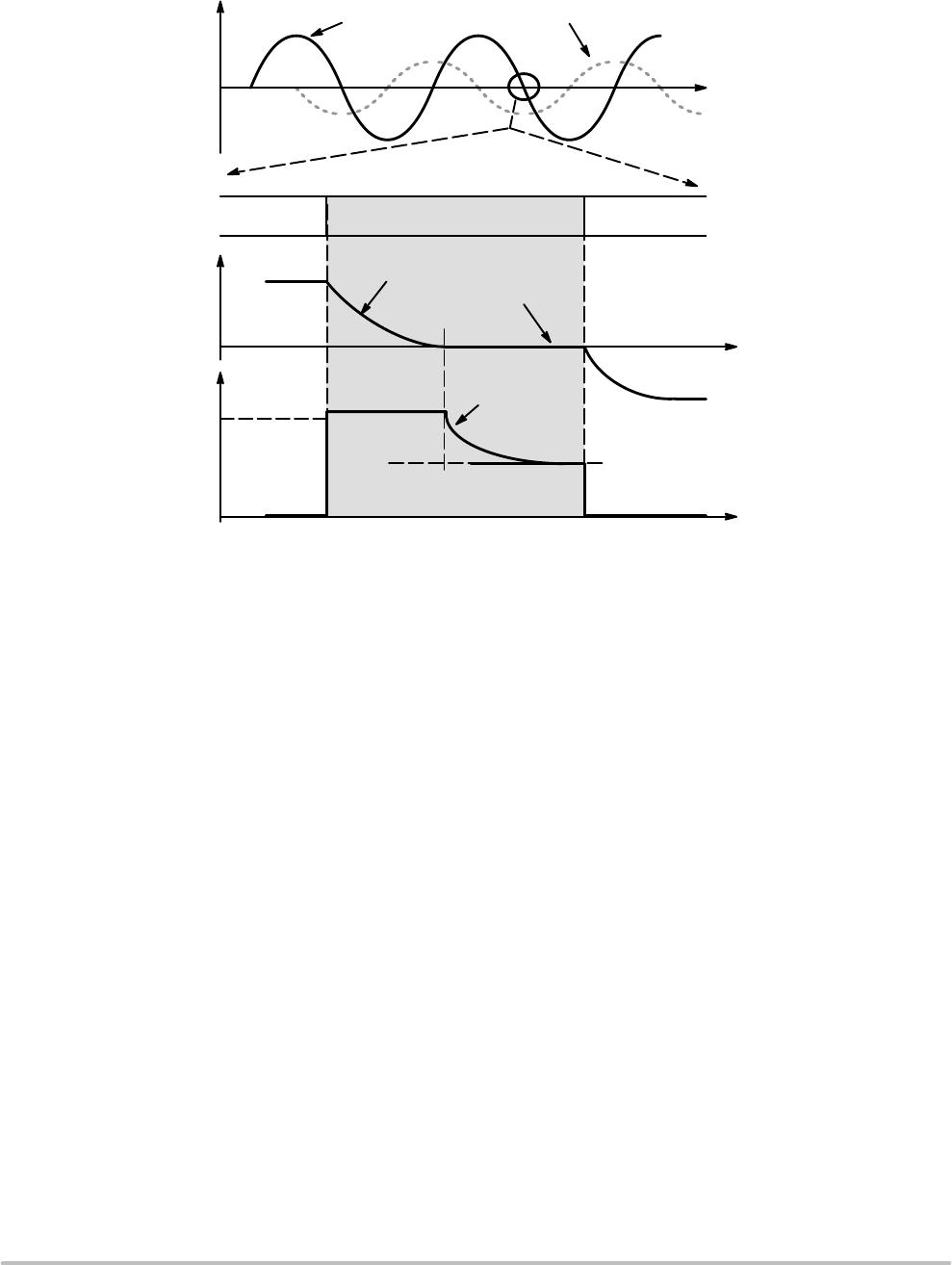

PWMsh

SLAT

SLA−Pin

last

retained

retain last sample

previous output is

buf

Ssh Sh

Ch

Csh

SLAT

NOT (Icoil=0)

Icoil=0

PWMsh

SLA−Pin

div2

div4

t

t

Figure 14. Timing Diagram of SLA−Pin

SLAT = 1 => SLA−pin is “transparent” during

V

BEMF

sampling @ Coil Current Zero

Crossing. SLA−pin is updated “real−time”.

SLAT = 0 => SLA−pin is not “transparent”

during V

BEMF

sampling @ Coil Current Zero

Crossing. SLA−pin is updated when leaving

current−less state.

V

COIL

V

COIL

V

BEMF

sample

is

kept at SLA pin

Icoil=0

Warning, Error Detection and Diagnostics Feedback

Thermal Warning and Shutdown

When Junction temperature rises above T

TW

, the thermal

warning bit <TW> is set (Table 16 SPI Status Register 0). If

junction temperature increases above thermal shutdown

level, then the circuit goes in “Thermal Shutdown” mode

(<TSD>) and all driver transistors are disabled (high

impedance) (Table 16 SPI Status Register 2). The conditions

to reset flag <TSD> is to be at a temperature lower than T

TW

and to clear the <TSD> flag by reading it using any SPI read

command.

Overcurrent Detection

The overcurrent detection circuit monitors the load

current in each activated output stage. If the load current

exceeds the overcurrent detection threshold, then the

overcurrent flag is set and the drivers are switched off to

reduce the power dissipation and to protect the integrated

circuit. Each driver transistor has an individual detection bit

in the Table 16 SPI Status Registers 1 and SPI Status

Register 2 (<OVCXij> and <OVCYij>). Error condition is

latched and the microcontroller needs to clear the status bits

to reactivate the drivers.

Note: Successive reading the SPI Status Registers 1 and 2 in

case of a short circuit condition, may lead to damage to the

drivers.

Open Coil Detection

Open coil detection is based on the observation of 100%

duty cycle of the PWM regulator. If in a coil 100% duty cycle

is detected for longer than 32 ms the appropriate status bit in

the SPI status register is set (<OPENX> or <OPENY>).

(Table 16: SPI Status Register 0).

When the resistance of a motor coil is very large and the

battery voltage is low, it can happen that the motor driver is

not able to deliver the requested current to the motor. Under

these conditions the PWM controller duty cycle will be

100% and after 32 ms, the error pin and <OPENX>,

<OPENY> will flag this situation (motor current is kept

alive). This feature can be used to test if the operating

conditions (supply voltage, motor coil resistance) still allow

reaching the requested coil−current or else the coil−current

should be reduced.