MAX1710/MAX1711/MAX1712

High-Speed, Digitally Adjusted

Step-Down Controllers for Notebook CPUs

______________________________________________________________________________________ 19

The actual microfarad capacitance value required relates

to the physical size needed to achieve low ESR, as well

as to the chemistry of the capacitor technology. Thus, the

capacitor is usually selected by ESR and voltage rating

rather than by capacitance value (this is true of tantalums,

OS-CONs, and other electrolytics).

When using low-capacity filter capacitors such as ceram-

ic or polymer types, capacitor size is usually determined

by the capacity needed to prevent the overvoltage pro-

tection circuit from being tripped when transitioning from

a full-load to a no-load condition. The capacitor must be

large enough to prevent the inductor’s stored energy from

launching the output above the overvoltage protection

threshold. Generally, once enough capacitance is added

to meet the overshoot requirement, undershoot at the ris-

ing load edge is no longer a problem (see also V

SAG

equation under Design Procedure).

With integrators disabled, the amount of overshoot due to

stored inductor energy can be calculated as:

where I

PEAK

is the peak inductor current. To absolutely

minimize the overshoot, disable the integrator first, since

the inherent delay of the integrator can cause extra “run-

on” switching cycles to occur after the load change.

Output Capacitor Stability Considerations

Stability is determined by the value of the ESR zero rela-

tive to the switching frequency. The point of instability is

given by the following equation:

For a typical 300kHz application, the ESR zero frequency

must be well below 95kHz, preferably below 50kHz.

Tantalum and OS-CON capacitors in widespread use at

the time of publication have typical ESR zero frequencies

of 15kHz. In the design example used for inductor selec-

tion, the ESR needed to support 50mVp-p ripple is

50mV/3.5A = 14.2mΩ. Three 470µF/4V Kemet T510 low-

ESR tantalum capacitors in parallel provide 15mΩ max

ESR. Their typical combined ESR results in a zero at

14.1kHz, well within the bounds of stability.

Don’t put high-value ceramic capacitors directly across

the fast feedback inputs (FB to GND) without taking pre-

cautions to ensure stability. Large ceramic capacitors

can have a high ESR zero frequency and cause erratic,

unstable operation. However, it’s easy to add enough

series resistance by placing the capacitors a couple of

inches downstream from the junction of the inductor and

FB pin (see the All-Ceramic-Capacitor Application sec-

tion).

Unstable operation manifests itself in two related but dis-

tinctly different ways: double-pulsing and fast-feedback

loop instability.

Double-pulsing occurs due to noise on FB or because

the ESR is so low that there isn’t enough voltage ramp in

the output voltage (FB) signal. This “fools” the error com-

parator into triggering a new cycle immediately after the

400ns minimum off-time period has expired. Double-

pulsing is more annoying than harmful, resulting in noth-

ing worse than increased output ripple. However, it can

indicate the possible presence of loop instability, which

is caused by insufficient ESR.

Loop instability can result in oscillations at the output

after line or load perturbations that can trip the overvolt-

age protection latch or cause the output voltage to fall

below the tolerance limit.

The easiest method for checking stability is to apply a

very fast zero-to-max load transient (see MAX1710

Evaluation Kit manual) and carefully observe the output

voltage ripple envelope for overshoot and ringing. It

can help to simultaneously monitor the inductor current

with an AC current probe. Don’t allow more than one

cycle of ringing after the initial step-response under- or

overshoot.

Input Capacitor Selection

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents.

Nontantalum chemistries (ceramic, aluminum, or OS-

CON) are preferred due to their resistance to power-up

surge currents:

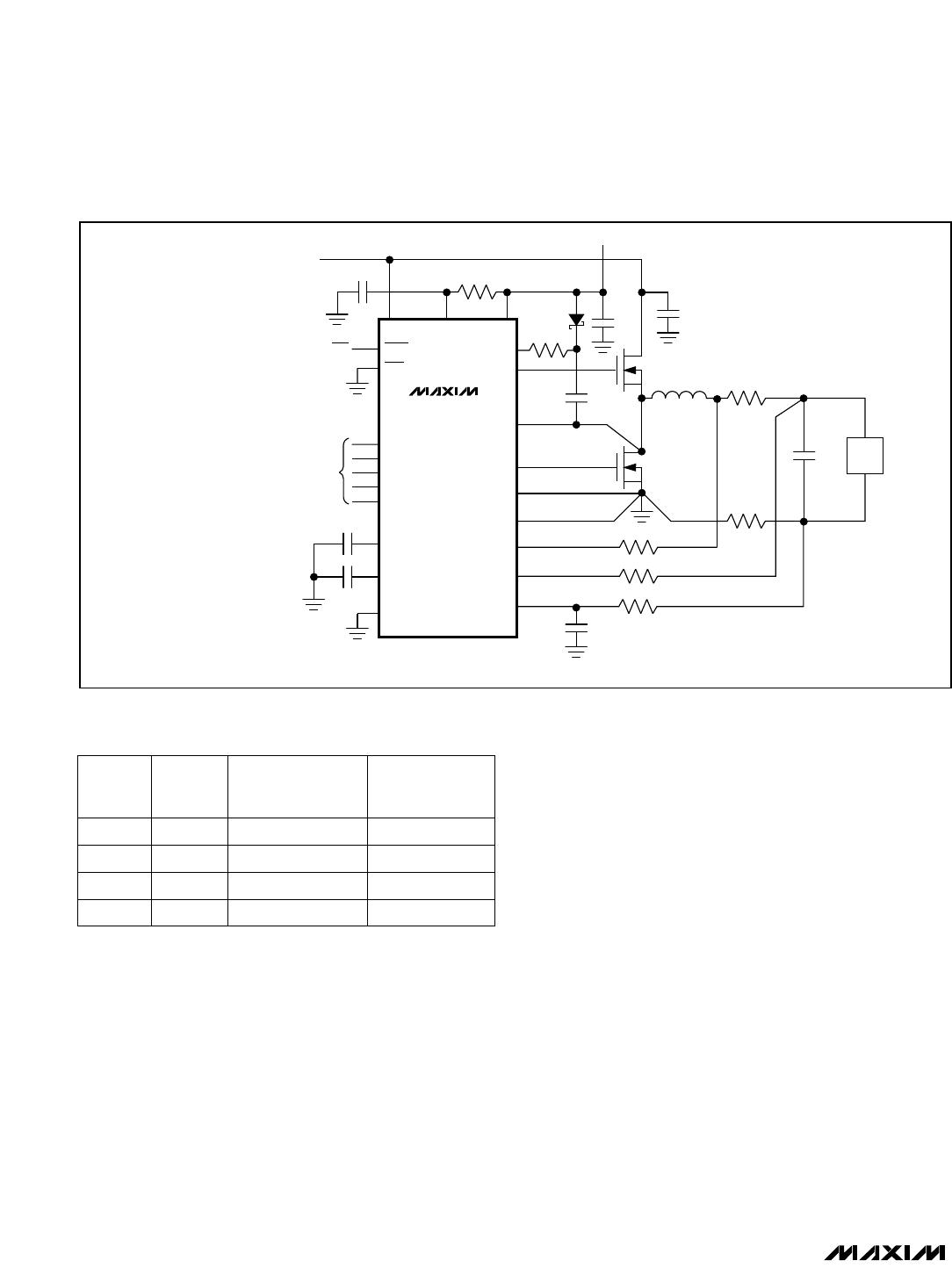

Power MOSFET Selection

Most of the following MOSFET guidelines focus on the

challenge of obtaining high load-current capability (>5A)

when using high-voltage (>20V) AC adapters. Low-cur-

rent applications usually require less attention.

For maximum efficiency, choose a high-side MOSFET

(Q1) that has conduction losses equal to the switching

losses at the optimum battery voltage (15V). Check to

ensure that the conduction losses at minimum input volt-

age don’t exceed the package thermal limits or violate

the overall thermal budget. Check to ensure that con-

duction losses plus switching losses at the maximum