By TE Connectivity 389

A multi-conductor cable is a cable that consists of multiple conductors, usually metallic wires. These conductors can be arranged in parallel inside the cable and separated and protected by insulation and shielding. Multi-conductor cables are commonly used to transmit multiple signals or power in one cable, and are suitable for various applications, from low frequency to high frequency, and from low speed to high speed.

The number of conductors in a multi-conductor cable can vary as required, usually with more than two conductors. Each conductor has its own place inside the cable and is isolated by proper insulation to prevent interference and short circuits between currents. In addition, in order to reduce the influence of external electromagnetic interference on the signal, multi-conductor cables can also have different types of shielding.

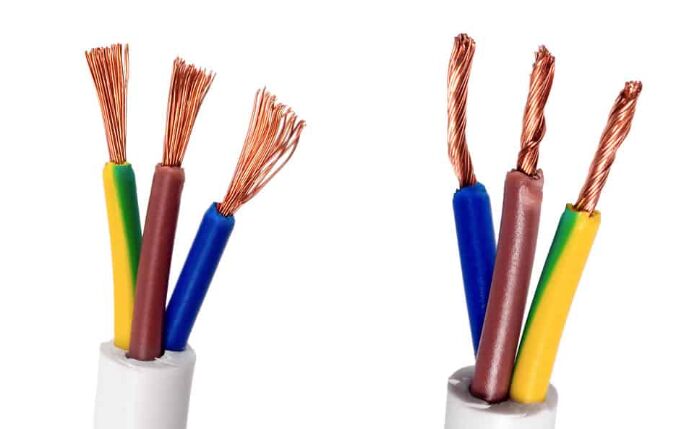

Multi-conductor cables usually consist of more than two conductors. The number of conductors can vary depending on the needs of the application, from a few to dozens. The conductors of multi-conductor cables are usually metallic wires such as copper or aluminum. Metal conductors have good electrical conductivity and mechanical strength and are suitable for various signal transmission and power distribution needs.

Each conductor is wrapped in an insulation layer to prevent current interference and short circuits between different conductors. Insulating materials can be PE, PVC, PP, etc.

To reduce the impact of external electromagnetic interference on the signal, multi-conductor cables can have different types of shielding. The shielding layer can be metal foil, woven wire mesh, etc. The shield helps prevent interfering signals from entering the cable, and also prevents signals carried by the cable from interfering with the outside environment.

The conductors of multi-conductor cables are usually arranged in parallel inside the cable, and each conductor has its own insulation layer. Multi-conductor cables may also have an outer sheath on the overall exterior to protect the conductors and insulation.

Multi-conductor cables are widely used in various fields and applications such as communications, data transmission, power distribution, instrumentation, automotive electronics, medical equipment and industrial control, etc. Depending on the requirements of the application, the number of conductors, insulation material, shielding method, etc. of the cable may vary.

When selecting multi-conductor cables, factors such as signal type, transmission distance, environmental conditions, electromagnetic interference, and anti-interference ability need to be considered. Choosing the right cable helps ensure the stability and quality of signal transmission.

Ⅰ. Working principle of multi-conductor cable

Electric Power Distribution: In power distribution, multi-conductor cables are used to transmit power from power stations to homes, industrial equipment, or other electrical consuming equipment. Each conductor is responsible for transmitting one phase of current (such as phase A, phase B and phase C in a three-phase power system). Through multiple conductors arranged in parallel, the cable can effectively transmit three-phase power to meet various load requirements.

Data transmission: In computer networking and data transmission, multi-conductor cables are used to connect computers, servers and network equipment. Each conductor can transmit different data signals, supporting high-speed data transmission. Insulation and shielding help ensure the quality and stability of data transmission.

Communication: In the field of communication, multi-conductor cables are used to transmit various signals such as telephone, network, audio and video signals. Different conductors can be used to carry different types of signals, and insulation helps prevent interference between signals. The shielding layer can reduce the impact of external electromagnetic interference on the signal.

Instrumental Measurements: In instrumental measurements, multi-conductor cables are used to transmit various measurement signals such as temperature, pressure and voltage signals. Different conductors can be used to connect different types of sensors in order to monitor and measure various physical quantities.

Ⅱ. Performance of multi-conductor cables in high frequency applications

1. Phase stability: In some high-frequency applications, such as radio frequency (RF) communications, phase stability is very important. Cable design and material selection can affect phase stability.

2. Signal attenuation: High-frequency signals will experience attenuation during transmission because the conductors and insulating materials of the cable will cause losses to the high-frequency signals. Therefore, in high-frequency applications, selecting low-loss cable materials and designs is key.

3. Impedance matching: In high-frequency applications, the characteristic impedance of the cable needs to match the connected equipment and transmission lines. Impedance mismatch can cause signal reflections and losses, reducing signal quality.

4. Material selection: The material of the cable, including conductors, insulation materials, shielding materials and outer sheaths, will affect its performance in high-frequency applications. For example, copper conductors are often used in high-frequency applications because of their lower resistance and losses.

5. High temperature resistance: Cables in high-frequency applications usually operate in high-temperature environments, so the cables need to have good high-temperature resistance to ensure stable operation for a long time.

6. Transmission rate: High-frequency applications usually require high-speed data transmission, so the transmission rate of the cable is very important. The cable's transmission characteristics, electromagnetic interference suppression capabilities, and signal-to-noise ratio all affect transmission rate performance.

7. Shielding effect: In high-frequency applications, electromagnetic interference has a more significant impact on signals. Therefore, the shielding effect of the cable is crucial to prevent external interference from entering the cable and affecting the signal quality.

8. Bandwidth: High-frequency applications require larger bandwidth to transmit broadband signals. The bandwidth of a cable determines whether it can support the transmission of high-frequency signals.

Ⅲ. Application of multi-conductor cables

1. Communication: Multi-conductor cables are used to transmit various communication signals, such as telephone, network, audio and video signals. They are widely used in telephone lines, optical fiber communications, television cable transmission and other fields.

2. Medical equipment: Multi-conductor cables are used in medical equipment to transmit various signals, such as those in vital sign monitoring, imaging equipment, and surgical instruments.

3. Data transmission: In computer networks, data centers and servers, multi-conductor cables are used to connect computers, switches, routers and other network devices to transmit data and realize network communication.

4. Sensor network: In the Internet of Things (IoT) and sensor network, multi-conductor cables are used to connect various sensors to transmit the collected data to the data acquisition and processing unit.

5. Power distribution: Multi-conductor cables are used to distribute electrical energy from power stations, substations or power sources to homes, industrial equipment, buildings and other electrical equipment. They have applications in both low voltage and high voltage power systems.

6. Audio and video transmission: Multiconductor cables are used for connections between audio and video equipment, such as audio systems, televisions, cameras, and audio、ideo recording equipment.

7. Automotive electronics: In automobiles, multi-conductor cables are used to connect various electronic devices and sensors, such as engine control units, dashboards, audio systems, and security systems.

8. Industrial control: In industrial automation and control systems, multi-conductor cables are used to connect sensors, actuators, PLCs (programmable logic controllers) and other control equipment for automation and monitoring.

9. RF application: Multi-conductor cables are used to transmit high-frequency signals in radio frequency communications, radar systems and microwave equipment.

Ⅳ. The difference between multi-conductor cables and single-conductor cables

1. Structure

Multi-Conductor Cable: A multi-conductor cable consists of multiple conductors (usually metallic wires) that are usually arranged in parallel on the inside of the cable and are separated and protected by insulation and shielding. The number of conductors can vary as required, usually there are more than two conductors.

Single Conductor Cable: A single conductor cable consists of only one conductor, usually a single metallic wire, and not multiple conductors arranged in parallel.

2. Electromagnetic interference

Multi-conductor cables: Multi-conductor cables usually have better electromagnetic shielding capabilities, which can reduce the impact of external electromagnetic interference on the signal. This is because their shielding and insulation better protect multiple conductors.

Single-conductor cables: Single-conductor cables generally do not have strong electromagnetic shielding capabilities because they contain only one conductor and are more susceptible to external electromagnetic interference.

3. Purpose

Multi-Conductor Cables: Multi-conductor cables are primarily used to transmit multiple signals or power in the same cable. They are commonly used in a variety of applications including communications, data transmission, power distribution, instrumentation, automotive electronics, medical equipment, and industrial control.

Single Conductor Cable: Single conductor cables are usually used for the transmission of a single signal or power connection. They may be used in power distribution, wire and cable, to connect a single device or in a specific application.

4. Specific applications

Multi-Conductor Cables: Multi-conductor cables are typically used in applications that require the transmission of multiple signals in the same cable, or where more complex circuitry is required. They are commonly found in communications, data transmission, and multi-signal sensor systems.

Single Conductor Cable: Single conductor cables are typically used for simple power distribution, single signal transmission, low cost applications, or specific applications that do not require multiple conductors.

Ⅴ. Shield type of multi-conductor cable

1. Spiral shielding

Is a type of cable shield that is braided from a helical layer of metal foil or wire. Spiral shielding is common in multi-conductor cables to reduce the effect of external electromagnetic interference on the signal.

Spiral shields are usually made of a thin layer of metal foil or wire that is spirally wrapped around a conductor to form a continuous shield. The shielding density can be varied as needed, and high-density shielding can provide better shielding effect.

Spiral shielding effectively isolates a conductor from external electromagnetic fields by wrapping a metal shield around the conductor. This can reduce the influence of external electromagnetic interference on the signal in the conductor, thereby improving the quality and reliability of the signal. Compared to other shield types, spiral shields offer higher flexibility because the metal shield is thin and bendable. This allows the cable to be installed and used more easily in applications that require bending or movement.

Spiral shields are often used in applications that require the transmission of high frequency signals, such as RF communications, audio and video transmission, etc. They can effectively reduce external electromagnetic interference and ensure the quality of high-frequency signals. Spiral shielded cables are commonly used in audio and video connections such as sound systems, audio/ideo equipment, televisions, and cameras.

2. Aluminum foil shielding

Is a type of cable shielding that is usually made of a thin layer of aluminum foil that goes either around the conductors of the cable or over the insulation. Aluminum foil is a thin, flexible metal material commonly used for shielding. It has good electrical conductivity and electromagnetic shielding properties.

Aluminum foil shielding can be placed around the conductors of the cable or over the insulation, depending on the specific design. In some cases, it can be used with braided shields for enhanced shielding effectiveness. Typically, foil shields are grounded to enhance their shielding effectiveness. Grounding removes unwanted electromagnetic energy to the ground, reducing interference with the signal.

Due to its excellent high frequency shielding properties, aluminum foil shielded cables are very common in RF and microwave applications such as satellite communications, radar systems and communication antennas. Aluminum foil shielding is also used in electromagnetic compatibility testing and equipment to reduce electromagnetic radiation and electromagnetic susceptibility to ensure the normal operation of equipment in the electromagnetic environment.

3. Braided shielding

Is a type of cable shield usually constructed of a woven wire mesh, such as copper or aluminum. Braided shielding is widely used in the construction of cables and wires to reduce the effect of external electromagnetic interference on the signal.

Braided shields are constructed of woven wire mesh, usually made of copper or aluminum. Braided wire mesh is tightly wrapped around the conductors of the cable or over the insulation. The shielding density of braided shielding can be varied according to needs, and high-density braided shielding can provide stronger shielding effect.

In industrial control and automation applications, braided shielded cables are used to connect sensors, actuators and control equipment to reduce the impact of electromagnetic interference on control systems.

4. Composite shielding

It is a type of cable shielding that combines several different types of shielding technologies to provide a stronger shielding effect to reduce the impact of external electromagnetic interference on the signal. Composite shielded cables typically have multiple layers of shielding including aluminum foil, braided shielding, or other types of shielding. These layers can be stacked on top of each other to provide higher shielding density and performance.

Composite shielded cables may use a number of different materials to construct the shield, such as aluminum foil, copper foil, braided wire mesh, etc. Such a composite structure can provide more comprehensive shielding in different frequency ranges. Like other shielding types, composite shielding is usually grounded to enhance its shielding effect, expelling unnecessary electromagnetic energy to the ground and reducing signal interference.

5. Surround shielding

Is a type of cable shielding that differs from other types of shielding. It usually consists of a thin layer of foil or wire wrapped around each conductor of the cable, rather than the entire outside of the cable. Surround shielding is characterized by wrapping a layer of metal foil or wire around each conductor (usually insulated), rather than covering the entire outside of the cable. This means that each conductor has its own shield.

The shield is usually separated from the conductors by a layer of insulating material to ensure that the conductors do not interfere with each other. This also helps reduce the capacitance of the cable. At the connection end, it is usually necessary to connect each shield to the grounding system of the cable to ensure the effectiveness of the shield.

6. Composite insulation shielding

It is a type of cable shielding that combines a variety of different shielding technologies and insulation materials to provide a higher level of shielding and insulation to ensure the quality and reliability of signals within the cable.

Composite insulated shielded cables typically include multiple insulation layers made of different materials to provide better cable insulation. Composite insulation shields usually also include one or more shielding layers, such as aluminum foil, copper foil, braided shielding, or other types of shielding to reduce the effect of external electromagnetic interference on the signal.

This cable combines insulation and shielding to provide high performance in several ways. The insulation helps prevent signal leakage and interference between cables. Composite insulated shielded cables are often used in demanding applications sensitive to signal quality and electromagnetic interference, especially in high frequency, radio frequency, audio and video fields, such as audio production, sound system, RF communication, etc.

Ⅵ. Electromagnetic interference and anti-interference ability of multi-conductor cables

1. Shielding type: Different types of multi-conductor cables can use different types of shielding, such as spiral shielding, aluminum foil shielding, braided shielding or composite shielding. Different shielding types have different shielding properties, some of which can provide better EMI suppression.

2. High frequency and radio frequency applications: High frequency and radio frequency applications are generally more susceptible to electromagnetic interference, so multi-conductor cables require stronger shielding and anti-interference capabilities in these applications. Aluminum foil, braided shields, and composite shields generally perform better in high frequency and radio frequency applications.

3. Shielding density: The higher the shielding density, the stronger the resistance of the cable to external electromagnetic interference. High-density shielding can effectively prevent external electromagnetic fields from entering the cable and reduce interference to signals.

4. Environmental conditions: Cables may behave differently under different electromagnetic environmental conditions. For example, in an industrial environment, there are a large number of sources of electromagnetic interference, and cables need stronger anti-interference capabilities.

5. Grounding: The shielding of the cable usually needs to be grounded to enhance its anti-interference ability. Good grounding can exclude unnecessary electromagnetic energy to the ground and reduce interference to signals.

6. Cable length: The length of the cable will also affect its electromagnetic interference and anti-interference ability. Longer cables may be more susceptible to interference, so stronger shielding may be required.

Ⅶ. Precautions for maintenance and installation of multi-conductor cables

1. Precautions for installation

Proper Connectors and Connections: Use proper cable connectors and connectors to ensure stable and reliable connections. Check connections regularly to make sure they are not loose or corroded.

Route cables correctly: When installing cables, ensure that the conductor arrangement and cable layout are as designed. Proper alignment and placement can help reduce electromagnetic interference and signal crosstalk.

Protecting cables: Use cable jackets (cable sheaths) to protect cables from physical damage and environmental influences such as water, chemicals, and UV rays.

Avoid tight bend radii: Different types of cables have different minimum bend radii requirements. Make sure not to bend the cable beyond its minimum allowable bend radius to prevent damage to the insulation and conductors.

Avoid Pull: Avoid applying excessive pull or tension during installation to prevent conductor breakage or insulation damage.

2. Maintenance

Maintenance records: Record the maintenance history of the cable, including installation dates, maintenance activities and test results. This helps identify and resolve problems promptly.

Periodic inspection: Periodically inspect the appearance of the cable, including the sheath and connections, to ensure there is no visible damage or wear.

Temperature Control: When using cables in high or low temperature environments, make sure the cables can withstand the required operating temperature range.

Keep it Clean: Keep your cables clean to avoid the buildup of sediment and dirt, which can cause poor heat dissipation or damage to the cables.

Be aware of electromagnetic interference: For applications that require resistance to electromagnetic interference, ensure that the cable's shielding system and grounding system are functioning properly to minimize external interference.

Regular testing: Perform regular cable testing, including resistance, insulation resistance and shielding effectiveness testing, to ensure normal cable performance.

Fire and explosion protection measures: For certain applications, such as hazardous areas or flammable gas environments, take appropriate fire and explosion protection measures to ensure the safety of the cable.

Ⅷ.Signal transmission characteristics of multi-conductor cables

Phase Stability: In some applications, the phase stability of a signal is very important, especially in RF and microwave applications. Multi-conductor cables generally provide good phase stability, ensuring that the signal phase remains consistent.

Transmission Loss: Transmission loss is the energy lost when a signal is transmitted in a cable. It is usually measured in decibels (dB) and is related to cable length, frequency and cable characteristics. The lower the transmission loss, the better the signal transmission performance of the cable.

Frequency Response: The frequency response of a multi-conductor cable refers to its ability to transmit signals of different frequencies. Frequency response is typically measured in terms of the cable's impedance characteristics and signal attenuation. Some cables may perform better in certain frequency ranges and perform worse at other frequencies.

Cable Capacitance and Inductance: Multi-conductor cables have certain capacitance and inductance, which affects the signal transmission speed and frequency response. Lower cable capacitance and inductance generally facilitate the transmission of high frequency signals.

Signal Distortion: Signal distortion includes time domain and frequency domain distortion of the signal, usually due to signal transmission delay, waveform deformation or harmonics. Cable design and characteristics can affect the degree of signal distortion.

Signal Attenuation: Signal attenuation is the degree to which a signal weakens during transmission in a cable. It is related to the characteristics, frequency and length of the cable. High frequency signals are generally more susceptible to attenuation.

Crosstalk: Crosstalk is the undesirable effect of signals on one conductor on signals on other conductors in multi-conductor cables. Cable design and shielding type can reduce the occurrence of crosstalk.

EMC: The design and shielding of a multi-conductor cable often affects its susceptibility to external electromagnetic interference and thus electromagnetic compatibility.

Frequently Asked Questions

1. What are the conductor arrangements of multi-conductor cables?

Common conductor arrangements include side-by-side arrangement, multi-layer arrangement, concentric conductor arrangement, spiral arrangement, twisted arrangement, and beam arrangement.

2. What are the price and cost factors for multi-conductor cables?

The specifications of the cable include the number of conductors, the cross-sectional area of the conductors, the length of the cable, and the type of shielding. Larger gauge or more complex cables are usually more expensive. The specification of the cable will also be influenced by the needs of the application, so it may need to be customized according to specific needs. The material a cable is made of has a significant impact on its cost. The cost of conductors, insulation, jacket material, shielding, etc. all contribute to the total cost of the cable. Specialty or high-performance materials are usually more expensive.

3. How to choose a suitable multi-conductor cable?

Identify application needs, select cable type, determine required cable specifications and performance characteristics, determine cable length, and layout to ensure cables are long enough and will not bend or otherwise be unduly stressed during installation.

4. What are the standards and specifications for multi-conductor cables?

TIA publishes standards related to communications and networking cables, including standards for Ethernet, telephony, and data center cables. IEC is an international organization that formulates electrical and electronic standards. It publishes many standards related to cables, including standards for cable design, materials, testing and performance.